Categories

- Ceramic Capacitors(2)

- 1

What are ceramic capacitors?

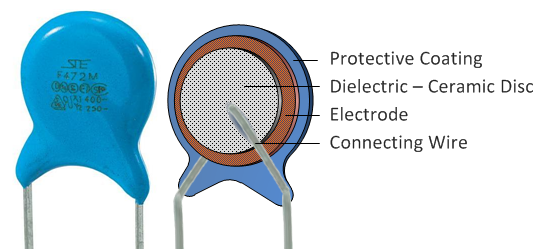

Ceramic capacitors use ceramic material as their insulator. This is one of the first materials used in capacitors because it insulates well. Some designs have been used in the past, but some, like ceramic tubular and barrier layer capacitors, have been replaced because they are too big, have unwanted effects, or don't work well. Today, the most common types of ceramic capacitors are the multi-layer ceramic capacitor (MLCC) and the ceramic disc capacitor. MLCCs are made using SMD technology and are produced at a rate of about 1 trillion units a year. They're popular because they're small, making them ideal for tight spaces.

These capacitors usually have capacitances of 1nF to 1µF, but can reach 100µF. Ceramic capacitors are small and can be used in alternating current (AC) circuits. They have a clean and efficient frequency response.

Applications for ceramic capacitors

MLCCs are the most widely produced capacitor in the electronics industry, so there are many applications for them. A resonant circuit in transmitter stations is an interesting high-precision, high-power application. Class 2 high-power capacitors are used in high-voltage laser power supplies, circuit breakers, and furnaces. SMD capacitors are used in printed circuit boards and high-density applications. Some are as small as a grain of sand. They are also used in DC-DC converters that put a lot of stress on the components. Ceramic capacitors can be used as general-purpose capacitors because they are not polarized and come in many types, sizes, and voltages. Many hobbyists use ceramic disc capacitors in brush DC motors to reduce RF noise.