What Temperature Sensor is & How It Works

Catalog

Description of Temperature SensorWhat do Temperature Sensors do?Uses of Temperature SensorsHow Temperature Sensors WorkTemperature Sensor ComponentsWhat are the classes and types of temperature sensors?Classes of Temperature SensorsTypes of Temperature SensorsNegative Temperature Coefficient (NTC) ThermistorWhat are the applications and benefits of temperature sensors?Benefits of Temperature SensorsHow to Choose the Right Temperature SensorEffective Temperature Control Using Temperature SensorsBalance the Cooling and Heating CapacityKeep Process Variables ConsistentUse the Correct Proportional ControllerConclusionDescription of Temperature Sensor

Terminal block accessories are little parts that help improve how terminal blocks work and keep things organized in electrical and electronic systems. Here's a quick rundown:

Temperature Sensors

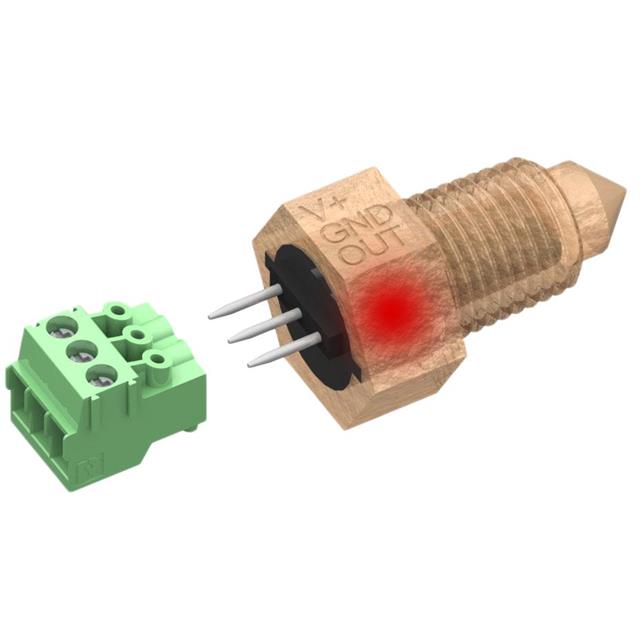

A temperature sensor is a simple gadget that measures temperature and changes it into something we can easily read. There are special kinds of sensors made for specific jobs, like checking the temperature in boreholes, soil, big concrete structures, or buildings.

What do Temperature Sensors do?

Temperature sensors basically measure how hot or cold something is. They work by using the voltage across a diode. The diode’s resistance changes with the temperature — if it gets colder, the resistance goes down, and when it heats up, the resistance goes up. This resistance is then converted into a temperature that we can easily read, usually shown as a number. In geotechnical monitoring, these sensors are used to check the internal temperatures of things like dams, bridges, and power plants.

Uses of Temperature Sensors

There are a bunch of different types of temperature sensors, but one of the main ways to group them is by how they connect. You’ve got contact and non-contact sensors. Contact sensors, like thermistors and thermocouples, need to touch the object they’re measuring. On the other hand, non-contact sensors measure the heat by picking up radiation from the source.

Uses of Temperature Sensors

These temperature meters are often used in risky places like thermal or nuclear power plants. They also measure hydration heat in big concrete structures and help with geotechnical monitoring, like tracking seepage and groundwater movement.

Temperature sensors are also really common in concrete curing since concrete needs to stay warm to set and cure properly. Seasonal changes can make structures expand or contract, which can change their overall size a bit.

How Temperature Sensors Work

A temperature sensor works by looking at the voltage across a diode’s terminals. When the temperature goes up, the voltage increases, while the voltage between the transistor’s base and emitter goes down. Some sensors even use stress changes caused by temperature shifts to work.

For a vibrating wire temperature meter, different metals expand at different rates. This device has a high-tensile magnetic wire stretched between two different metals. When the temperature changes, it affects the wire’s tension and the natural frequency at which it vibrates.

One of the metals used could be aluminum since it has a higher expansion rate than steel. The temperature is turned into frequency, and the same read-out unit used for other vibrating wire sensors can also be used to monitor temperature.

The vibrating wire sensor picks up temperature changes and turns them into an electrical signal, which gets sent to the read-out unit as a frequency.

Temperature Sensor Components

There are three main types of components in temperature sensors. The key parts include things like thermocouples or extension cables and wires, as well as the sensing elements. Other parts that help complete the sensor are insulating beads, connectors, connecting heads, and protective tubes. There are also extra components that are needed when using sensors, like converters and controllers.

Temperature Sensors in Control and Compensation Circuits

To use a temperature sensor in a control or compensation circuit, the detection circuit needs to give an output that’s easy to work with. In analog circuits, this output is usually resistance. For digital control or compensation, you need to convert the measurement into a digital format, which is typically done by measuring the output voltage with an analog-to-digital converter (ADC) that can be processed by a microcontroller (MCU).

Semiconductor-Based Sensors

Semiconductor sensors have a digital interface, which makes it easy for them to communicate with an MCU. These can read thermocouples because of their voltage output. RTDs and thermistors can give either voltage or resistance, giving engineers some flexibility when connecting detectors to control or compensation systems.

RTDs and thermistors provide variable resistance, which makes it easier to hook them up to analog control or compensation circuits. If you need a voltage output, you can convert the resistance to voltage using a Wheatstone bridge setup with three other resistors, as shown below.

Wheatstone bridge configuration

Non-linear sensors like thermocouples and thermistors need simple linearization of their output. For analog control, this can be done with a basic circuit. For digital control and compensation, the CPU can use a lookup table to adjust the temperature based on the sensor’s temperature/resistance chart, usually found in the spec sheet.

Engineers have different ways to design temperature detection circuits to avoid overheating or handle temperature control. Thermocouples work great for extreme temperatures, while platinum RTDs give high precision when accuracy is key. For PCB-based applications where it’s tough to install internal sensors, semiconductor-based sensors can detect ambient temperatures around sensitive electronics.

Temperature Sensor Elements

RTD elements are the key part of temperature sensors, acting as the resistance element in resistance thermometers or RTDs. You usually won’t find these elements in their raw form—they’re built into probes or assemblies that can handle different environments. Each RTD has a set resistance value at a known temperature, and this resistance changes predictably. By measuring the resistance, the temperature can be worked out using calculations, tables, or instruments.

Thin Film Temperature Elements

RTD elements are mass-produced using machines that deposit a thin layer of platinum onto a ceramic base. Photolithography is then used to etch an electrical path with the right resistance in ohms. These thin film elements are smaller than the old wire-wound types, which gives them faster response times and makes them useful in more situations, while also cutting costs for users.

Ceramic Temperature Elements

Ceramic elements are used in temperature sensors and can be wound on ceramic or glass forms, or a platinum wire helix can be partly supported inside a ceramic tube. This semi-supported design gives a wide temperature range and usually the best stability. While other metals can be used, platinum is the most common and is often paired with ceramic or glass insulators.

Using metals other than platinum can cause linearity issues at low temperatures and drifting, which messes with temperature accuracy. Having to constantly correct these errors is why platinum is the go-to choice.

Thermometrics can also add lead wires to the temperature sensor elements based on what’s needed. A common choice is 20 AWG, Teflon-coated nickel wires.

Glass Temperature Elements

Wire-wound elements sealed in glass (like quartz) are also available for specific user needs.

What are the classes and types of temperature sensors?

This chapter will explore various classes and types of temperature sensors used in control and compensation circuits, as well as their sensor elements.

Classes of Temperature Sensors

Temperature sensors come in various types, sizes, and shapes. They are generally categorized into two main classes: contact and non-contact temperature sensors.

Contact Temperature Sensors

Some temperature meters measure hotness or coldness by directly contacting the object. These contact-type sensors can detect temperature in liquids, solids, or gases across a wide range.

Non-Contact Temperature Sensors

These temperature meters do not require direct contact with the object. Instead, they measure temperature based on the radiation emitted by the heat source.

Types of Temperature Sensors

Temperature sensors are categorized into contact and non-contact types, each further divided into specific varieties as outlined below.

The Resistance Temperature Detector (RTD)

This device, known as a resistance thermometer, measures temperature by utilizing the resistance of a resistance temperature detector (RTD) element, which varies with temperature. Various materials can be employed to construct the metal element of the RTD.

Resistance Temperatutre Detector

The materials used include nickel, platinum, and copper. But platinum is the most accurate, which is why it’s also the most expensive.

Thermocouple Sensor

A thermocouple sensor is made up of two wires made from different metals, connected at two spots. The temperature difference shows up as a voltage difference between the two wires.

thermocouple sensor

While thermocouples might not be as accurate as RTDs, they cover a wide temperature range, from -328°F to 3182°F (-200°C to 1750°C), and they’re usually more budget-friendly.

Thermocouples come in different types, each designed for specific temperature ranges and suited for particular applications.

| Thermocouple Types | |||||

|---|---|---|---|---|---|

| Thermocouple Type | Temperature Range (°C) | ||||

| Short Term Use | Continuous Use | Class 1 Tolerance | Class 2 Tolerance | Class 3 Tolerance | |

| Type E | -40 to 900 | 0 to 800 | -40 to 800 | -40 to 900 | -40 to 904 |

| Type J | -180 to 800 | 0 to 750 | -40 to 750 | -40 to 750 | N/A |

| Type K | -180 to 1300 | 0 to 1100 | -40 to 1000 | -40 to 1200 | -180 to 1300 |

| Type N | -270 to 1300 | 0 to 1100 | -40 to 1000 | -40 to 1200 | -270 to 1304 |

| Type R | -50 to 1700 | 0 to 1600 | 0 to 1600 | 0 to 1600 | N/A |

| Type S | -50 to 1750 | 0 to 1600 | 0 to 1600 | 0 to 1600 | N/A |

| Type T | -250 to 400 | -185 to 300 | -40 to 350 | -40 to 350 | -250 to 404 |

| Type B | 0 to 1820 | 200 to 1700 | N/A | 600 to 1700 | 4 to 1820 |

Uses for Different Thermocouple Types:

- E: Good for vacuum, inert, mildly oxidizing, or reducing conditions.

- J: Works in areas with limited oxygen.

- K: Needs metal or ceramic protection.

- N: Resists oxidation from sulfur.

- T: Can be used in oxidizing or reducing environments.

- S, R, B: Must be protected with tubing, used in high-temperature applications.

- C (tungsten/rhenium): Very common; needs protective sheathing and is used for high temperatures.

- A: A variant of type C, but with limited use.

Type E Thermocouples

Type E thermocouples are made from chromel (a nickel-chromium alloy) and constantan. They can handle temperatures from -330°F to 1600°F (-200°C to 870°C) and have great EMF (electromotive force) vs. temperature characteristics. These thermocouples work well in sub-zero temperatures and inert environments, but they need protection when used in sulfurous conditions.

Type J Thermocouples

Type J thermocouples, similar to Type K, are general-purpose sensors made from iron and constantan, where the iron leg is positive and the constantan leg is negative. You can use them exposed or with a protective tube, which is recommended for durability. They work well in vacuum, inert, and reducing environments. Like Type K, Type J thermocouples need careful calibration and can be sensitive to electrical noise.

Type K Thermocouples

Type K thermocouples are made from Chromel®–Alumel® with small amounts of manganese and silicon. These are also general-purpose thermocouples with a temperature range of -328°F to 2462°F (-200°C to 1350°C). They need careful calibration and produce small output signals. You’ll find them in lots of different environments, including water, mild chemicals, gases, and dry conditions. Hospitals and food prep industries commonly use Type K thermocouples. Even though they cover a wide range, they’re mostly used for temperatures over 1004°F (540°C).

Type N Thermocouples

These are made from nicrosil (a nickel-chromium alloy) and nisil (nickel, silicon, and magnesium). They work in a range of 32°F to 2300°F (650°C to 1260°C) and are resistant to green rot and hysteresis. They’re often used in refineries and the petrochemical industry.

Type R Thermocouples

Made from platinum and rhodium, Type R thermocouples can measure up to 2700°F (1480°C). They need protection with a gas-tight ceramic tube and an extra outer tube. These thermocouples offer better stability and a wider temperature range than Type S, and you’ll see them in heat treatment, semiconductor manufacturing, glass production, and metal processing.

Type S Thermocouples

Known for their precision and stability, Type S thermocouples are great for high-temp applications in BioTech and Pharmaceutical industries, as well as low-temp situations. Their range is -58°F to 2700°F (980°C to 1450°C).

Type T Thermocouples

With copper and constantan, Type T thermocouples are good for temperatures from -330°F to 700°F (-200°C to 370°C). They’re used in inert atmospheres and can resist moisture without breaking down. You’ll find them in food production and cryogenic environments.

Type B Thermocouples

Type B thermocouples are built for high temperatures, offering the highest range among thermocouples with impressive accuracy and stability. They’re made from platinum with 6% rhodium and platinum with 30% rhodium, working between 2500°F and 3100°F (1370°C to 1700°C).

Type C Thermocouples

These thermocouples use tungsten and rhenium and can handle temperatures up to 4200°F (2315°C). They’re best in hydrogen, inert, or vacuum environments to avoid oxidation. They usually have protective sheaths made from molybdenum, tantalum, or inconel, and insulators like alumina, hafnia, or magnesium oxide.

Thermistor Sensor

This type of temperature sensor is super precise and shows consistent, significant changes when temperatures vary. These big changes allow for quick and accurate temperature readings.

Thermistor Sensor

Thermometer Temperature Sensor

This sensor usually comes in the form of a mercury-filled glass tube and is considered a standard type. There are different types of thermometers, but traditional glass ones often used mercury. Nowadays, though, ethanol is the main liquid used in these instruments.

Thermometer Temperature Sensor

Bi-Metal Thermometer

This thermometer has a gauge connected to a stem. At the tip of the sensor, a spring is attached to a rod that moves the needle on the gauge. The spring, located inside the stem, picks up on temperature changes at the end of the sensor. When heat hits the sensing coil, it makes the coil move, and that movement makes the needle on the gauge move, showing the temperature.

Bi-Metal Thermometer

Gas-Filled and Liquid Thermometer

These thermometers work in a similar way, featuring a bulb at the sensing end filled with either gas or liquid. When they get hot, the gas expands or the liquid heats up, which causes the rod to move and display the temperature on the gauge.

Gas-Filled and Liquid Thermometer

Digital Thermometer

This thermometer uses a probe, like a thermocouple or an RTD, to measure temperature. The sensing end of the probe captures the temperature and shows it as a digital reading on the display.

Digital Thermometer

Infrared Sensors

These temperature sensors can measure temperatures from a distance by looking at the thermal radiation emitted by a heat source or object. They’re super handy in high-temperature or hazardous environments where it’s important to stay safe and keep a distance from the heat source.

Infrared Sensors

Thermal Imaging

These are among the most popular non-contact temperature sensors. They’re especially useful in situations where the target object is moving (like on a conveyor belt), when it’s far away, or in hazardous environments and extreme temperatures where contact sensors just won’t cut it.

Thermal Imaging

Negative Temperature Coefficient (NTC) Thermistor

A thermistor is a temperature sensor that’s super sensitive to tiny temperature changes. It has high resistance at low temperatures, and that resistance drops quickly as the temperature goes up. The glass-coated NTC thermistor is known for its great accuracy, and it can detect even the smallest resistance changes per degree Celsius really fast.

NTC thermistors need a bit of linearization since their response follows an exponential curve. They work within a temperature range of -58°F to 482°F (-50°C to 250°C). Because of their sensitivity and quick response, linearization is important for NTC thermistors.

In a detection circuit, an NTC thermistor works by letting a small voltage pass through it. As the temperature rises, the thermostat’s resistance drops quickly, reflecting those temperature changes.

For temperature ranges between -40°F and 257°F (-40°C and 125°C), NTC thermistors are a more budget-friendly option compared to platinum RTDs, thermocouples, and semiconductor sensors. Their quick resistance changes mean they offer high accuracy, energy efficiency, stability, and responsiveness. Plus, NTC thermistors are easy to integrate into different systems.

Negative Temperature Coefficient (NTC) Thermistor

Semiconductor-Based Sensors

Semiconductor-based temperature sensors use two integrated circuits made up of two similar diodes. These diodes are really sensitive to temperature changes, so they can give precise temperature measurements based on their voltage and current characteristics.

Semiconductor-Based Sensors

These sensors provide a linear output, but they aren't super accurate in a narrow range of just 1 to 5°C. They also have the slowest response time, usually taking about 5 to 6 seconds, and they work within a limited temperature range of -94°F to 302°F (-70°C to 150°C).

Vibrating Wire Temperature Sensor

This type of temperature sensor is great for measuring internal temperatures in water or concrete structures. It has a resolution better than 0.1°C and works pretty much like a thermocouple sensor.

Vibrating Wire Temperature Sensor

Plus, it has a wide temperature range, from -4°F to 176°F (-20°C to 80°C).

What are the applications and benefits of temperature sensors?

This chapter will chat about the applications and benefits of temperature sensors. We’ll also cover how temperature sensors are used for temperature control.

Applications of Temperature Sensors

Temperature sensors are super important for measuring temperature in all sorts of applications and industries. You can find them everywhere, from factories to everyday life. Here are some examples of how temperature sensors come into play:

Industrial Applications

In industries, temperature sensors help keep an eye on different environments and equipment. They monitor water temperatures in reservoirs and boreholes, check for temperature-related stress and volume changes in dams, and study how temperature affects other installed instruments.

Scientific and Laboratory Applications

In science and biotech, temperature sensors are key for research and monitoring.

Medical Applications

In healthcare, temperature sensors are used for patient monitoring, medical devices, thermodilution, humidifiers, gas analysis, cardiac catheters, ventilator flow tubes, and managing the temperature of dialysis fluids.

Uses in Motorsports

In motorsports, they measure inlet air temperature, exhaust gas temperature, engine temperature, and oil temperature.

Domestic Appliances

You’ll find temperature sensors in kitchen gadgets like ovens and kettles, as well as in various household appliances.

HVAC Applications

Temperature sensors are crucial in heating, ventilation, and air conditioning systems for both homes and businesses.

Sensors in Transit

They’re also used in refrigerated vans and trucks to keep an eye on temperature during transport.

Benefits of Temperature Sensors

Temperature sensors come with a bunch of advantages, such as:

- They’re precise, super reliable, and pretty affordable.

- They work well for both embedded and surface applications.

- They have low thermal mass, which means they respond quickly.

- The vibrating wire temperature sensor is interchangeable, so all sensors can be read by one indicator.

- You can get temperature sensors with indicators for easy temperature display.

- Temperature probes have great hysteresis and linearity.

- The vibrating wire tech ensures long-term stability and quick readings.

- Temperature sensors are perfect for remote scanning, reading, and data logging.

How to Choose the Right Temperature Sensor

When you're picking out a temperature sensor for a specific application, there are a few things to keep in mind. Check out these key points when selecting your temperature sensor:

Temperature Range

Different temperature sensors are made for different temperature ranges, and they might be more accurate within certain limits. Before you buy, make sure the sensor's temperature range fits what you need. You can usually find this info in the sensor's datasheet.

Accuracy and Stability

Some applications have specific accuracy needs. Just a heads-up: thermocouples often have more long-term stability issues compared to thermistors and RTDs.

Size and Package

Your choice of temperature sensor also depends on the space you have in your setup. If space is tight, you might need a smaller device. Plus, the package style of the sensor can influence how it connects and measures temperature, so it's an important factor to consider.

Environmental Conditions

Where you place the temperature sensor really matters. The environment it’s going to work in can affect its performance. Things like humidity, vibrations, and other environmental factors can impact the sensor's stability and accuracy. Electrical noise can also mess with readings, especially when you're trying to detect small temperature changes. So, it’s super important to use the sensor in a low-noise environment to get reliable measurements.

To get the best performance, make sure to carefully evaluate the conditions and environment where the temperature sensor will be set up. Besides looking at the sensor’s design, you also want to protect any connections, like lead wires, from harsh and unstable conditions.

To keep a temperature sensor and its wiring safe from environmental issues, you can use protective measures like tough metal sheaths that resist wear and corrosion. While these sheaths are great for protection, they can also bump up the cost and affect sensitivity. Plus, some sensor setups need special mounting to make sure there’s a solid thermal connection.

Thermocouple Connecting Points

Effective Temperature Control Using Temperature Sensors

Temperature sensors are super important for keeping things under control when it comes to temperature. Here are five key factors for managing temperature efficiently:

Select the Right Sensor

When you’re designing a system, picking the right temperature sensor is usually one of the last decisions you’ll make. This choice often depends on how well it works with the system’s process controller, plus things like how easy it is to find and how much it costs. But don’t forget to consider essential factors like sensor mass, operating temperature, signal strength, reading sensitivity, and the conditions around it—these are often overlooked!

In commercial temperature control, there are three main types of sensors that are commonly used: thermistors, thermocouples, and resistive thermal devices (RTDs). Each type has its own unique features, and within each category, you’ll find different styles made for specific temperature ranges, output signals, and how they fit into the process, depending on the materials they’re made from.

It’s really important to choose a sensor that matches the specific needs of your design application. Sensor mass is a big deal: heavier sensors usually respond slower and with more lag to temperature changes, while lighter ones react faster. So, for applications that need precise temperature control, a lighter sensor is often the better choice because it can respond quickly.

Install the Sensor in the Correct Location

Where you put the temperature sensor is super important, even if it sounds simple. Sometimes, physical obstacles in the field can force you to change the original design location. If you can’t get the sensor in the best spot, think about other options and compromises that might work.

Temperature sensors on pcb

Anyway, where you place the sensor really matters for the whole system to work well. You definitely don’t want to compromise the system's efficiency just because it’s easier to install the sensor. Here are some tips to help you avoid common mistakes:

First off, make sure the sensor is positioned right at the entry point for the critical temperature. You want to ensure the process fluid is mixed well, without any cold or hot currents that could trick the sensor. Also, check that the sensor's location isn’t impacted negatively by changes in fluid velocity. And don’t forget to make sure no heating or cooling sources mess with the process fluid. For example, if there’s an uninsulated section of piping after the sensor but before the critical temperature point, it can totally affect the temperature you’re getting at that critical spot.

Balance the Cooling and Heating Capacity

The main goal of any temperature control system is to find a good balance between heating and cooling. If you don’t manage this energy balance well, you can end up with temperature instability. The two basic types of controls you usually see are proportional output control and on/off output control.

On/off control is the simplest to grasp. It works based on the system's temperature setpoint, kicking the heating or cooling system into full gear whenever the temperature strays from this setpoint. The system keeps running at full capacity until it hits that setpoint again, and then it shuts off. This can be a cost-effective way to go, especially if the mass of the process is bigger than the heating or cooling capacity and you’re okay with some temperature fluctuations.

But, there are some real limitations with this method. Since a system’s capabilities often surpass the load needs in different situations, just turning the heating or cooling equipment on and off isn’t usually practical.

To boost the control capacity of on/off systems, one option is to add multiple levels or stages of capacity into the heating or cooling system.

Keep Process Variables Consistent

It’s a lot easier to manage process control when all the equipment functions are predictable. But sometimes, energy-saving measures and management tweaks can actually throw temperature control off balance. Many modern systems are designed to automatically adjust a bunch of variables when load changes, which helps keep things stable even with those fluctuations.

Common variables that get adjusted in temperature control systems include the supply fluid temperature, process fluid volume, and heating or cooling capacities. Changing things like supply temperatures, process pressures, and fluid flow can alter how the system works, which might lead to temperature instability and control problems. For instance, if you change the flow rate of the process fluid in a plant chiller system, it can seriously affect performance.

A reduced flow rate can mess with heat-transfer characteristics in certain components and heat exchangers. This dip in heat transfer efficiency might lead to temperature instability at critical points and could even cause the compressor or other components to act up.

Use the Correct Proportional Controller

Proportional controllers usually come in three types: (PID) proportional plus integral plus derivative, (PI) proportional plus integral, and (P) proportional only. Thanks to advances in small process controllers, engineers have a lot more flexibility in their designs.

New technology in controllers has improved their ability to make up for flaws in system design and unpredictable characteristics. The simplest type of controller is the proportional controller, which is the foundation for a lot of small electronic devices. A proportional controller works by reacting to temperature deviations, creating an output signal based on a linear calculation where changes in deviation lead to a proportional change in output.

Conclusion

A temperature sensor is basically a simple tool that measures how hot or cold something is and turns that into a readable unit. There are all sorts of temperature sensors out there, like thermocouples, thermistors, and RTDs. Each one has its own special traits that make it better for certain applications. But when you're choosing a temperature sensor, it’s super important to think about things like the temperature range, accuracy, size, and stability to make sure it performs optimally for what you need.

Subscribe to JMBom Electronics !