Differernce Between Polarized and Non-Polarized Capacitors

Catalog

What are Polarized Capacitors?What are Non-Polarized Capacitors?Polarized vs. Non-Polarized Capacitors: Key DifferencesCan we use a Non-Polarized Capacitor instead of a Polarized One?Do I need a Polarized Capacitor?Final ThoughtsFrequently Ask QuestionsIf you’re into electronics, you’ve probably seen the terms polarized and non-polarized capacitors when shopping for parts. This guide breaks down what each type is, how they differ, and when to use them, so you don’t have to puzzle it out yourself.

We’ll walk through the key differences, share some practical usage tips, and look at common applications for both types. Ready to dive into the details of polarized vs. non-polarized capacitors? Let’s get started.

What are Polarized Capacitors?

Polarized Capacitors

Polarized capacitors are a type of capacitor that must be connected the right way around in a circuit in order to work properly.

One lead has to be connected to the positive voltage, and the other to the negative (or lower) voltage. To make this clear, the positive terminal is usually marked with a “+” symbol, and the negative terminal may have a “–” symbol or a stripe on the body.

In most polarized capacitors, the anode and cathode are separated by a dielectric layer (this is often an electrolyte or polymer film), while the electrodes themselves are made from metals or metal oxides. This structure allows them to achieve very high capacitance values in a relatively small package, which is why they’re widely used when a large amount of charge storage is needed.

Polarized capacitors are used in many circuit functions. They can help boost output voltage, smooth out ripple, and reduce noise in power supplies. They also play a role in protecting sensitive electronics from issues such as electrostatic discharge.

However, correct installation is essential. If a polarized capacitor is connected the wrong way round, it can fail or even damage nearby components. Always double-check the polarity markings before soldering or powering up your circuit.

What are Non-Polarized Capacitors?

Non-polarized capacitors are energy storage components that hold electrical energy in the form of an electric field. They consist of two conductive plates separated by an insulating material (dielectric), which can be ceramic, paper, plastic film, air, or even a vacuum.

Unlike polarized capacitors, non-polarized types don’t have a positive or negative terminal. This means they can be connected in either direction in a circuit, making them especially useful in AC applications where current changes direction constantly.

In AC circuits, non-polarized capacitors are often used to reduce power loss, filter out noise, and improve overall signal quality. They’re also widely used in DC circuits, including power supplies, motor control circuits, and timing or coupling applications.

These capacitors typically offer:

- A wide range of capacitance values

- Better tolerance to temperature changes

- Higher voltage ratings (depending on type)

Because they are available in many sizes, voltage ratings, and tolerance options, non-polarized capacitors are a flexible choice for everything from audio equipment (for signal coupling and noise filtering) to general-purpose electronic designs.

Polarized vs. Non-Polarized Capacitors: Key Differences

Now that you know the basics of both types, let’s look at how polarized and non-polarized capacitors differ in practice.

1. Structure

Capacitors come in many shapes and sizes—cylindrical, square, box-type, or tubular—and their external shape doesn’t really affect how they work in normal use.

Electrolytic (polarized) capacitors are most commonly cylindrical, while many non-polarized capacitors (like ceramic or film types) are typically rectangular or box-shaped.

In high-frequency or intermediate-frequency circuits, the internal structure and layout can introduce small “parasitic” or distributed capacitances, which designers need to take into account even though they’re not visible from the outside.

2. Dielectric Material

Polarized capacitors (such as electrolytic capacitors) use an electrolyte and a very thin oxide layer as the dielectric. This allows them to achieve much higher capacitance values for a given size compared with most non-polarized types. The exact capacitance depends on the electrolyte material and manufacturing process.

Non-polarized capacitors typically use dielectrics like ceramic, polyester film, polypropylene film, paper, or other insulating materials. The dielectric largely determines:

- The voltage rating

- Stability over temperature

- Whether the capacitor is better suited as polarized (electrolytic, tantalum) or non-polarized (ceramic, film, etc.)

3. Frequency Characteristics

Non-polarized capacitors generally perform better at higher frequencies. That’s why ceramic capacitors and film capacitors are commonly used in:

- Audio circuits (for coupling and filtering)

- Motor control circuits

- High-frequency filtering and decoupling

Polarized capacitors, especially electrolytics, are better suited to lower-frequency applications such as smoothing DC in power supplies. Their characteristics make them less ideal for high-frequency signal paths.

4. Capacitance Range

Polarized capacitors can provide much higher capacitance values than most non-polarized capacitors of similar size. This makes them a great choice for:

- Power supply filtering

- Voltage regulation circuits

- Bulk energy storage

Non-polarized capacitors typically come in lower capacitance values but offer better performance at high frequency, better stability, and more precise tolerances in many cases.

In short:

- Use polarized capacitors when you need high capacitance and are working mainly with DC (e.g. power supplies).

- Use non-polarized capacitors when you need good high-frequency performance, bidirectional operation (AC), or more stable and precise behavior.

Can we use a Non-Polarized Capacitor instead of a Polarized One?

In some cases, yes — you can use a non-polarized capacitor in place of a polarized capacitor, as long as certain conditions are met.

Non-polarized capacitors don’t have polarity, so they don’t suffer from reverse-voltage issues the way electrolytic (polarized) capacitors do. If you choose a non-polarized capacitor with the same or higher capacitance and voltage rating as the original polarized part, it can often work as a substitute, especially in AC or signal paths.

However, there are a few important points:

- Non-polarized capacitors of the same capacitance and voltage rating are usually larger and more expensive than polarized electrolytics.

- Polarized capacitors are typically used where the voltage across them is always of one polarity (e.g. DC power supply filtering).

- If you’re sure the circuit always applies voltage in a single direction and you need high capacitance in a compact, low-cost package, a polarized capacitor is usually the better choice.

So, while a non-polarized capacitor can sometimes replace a polarized one, the reverse is not always safe. Always check the circuit type (AC vs DC, frequency, and voltage) before swapping.

Do I need a Polarized Capacitor?

You generally need a polarized capacitor when:

- You’re filtering or smoothing DC power supplies (bulk energy storage).

- You’re coupling amplifier stages and blocking DC while letting AC signals pass, especially at audio or low frequencies.

- You require very high capacitance values in a small, cost-effective package.

Polarized capacitors (like electrolytics):

- Provide large capacitance in a compact size.

- Are widely used in power supplies, voltage regulators, and audio amplifier circuits.

Non-polarized capacitors, by comparison, are often preferred in high-frequency or AC applications, but for low-frequency, high-capacitance DC work, a polarized capacitor is usually the more practical and economical option.

Final Thoughts

In simple terms, polarized capacitors have a clearly defined positive and negative lead, while non-polarized capacitors do not. This difference in polarity leads to differences in:

- Performance characteristics

- Capacitance range

- Construction and materials

- Suitable operating environments and applications

We’ve covered the main differences between polarized and non-polarized capacitors, along with where each type is typically used and what advantages they offer.

In the end, choosing between them comes down to your circuit requirements: voltage type (AC or DC), required capacitance, frequency, size, and cost.

Frequently Ask Questions

What do polarized capacitors do?

Polarized capacitors are used when you need very large capacitance in a compact, cost-effective package. They are most commonly used to:

- Filter and smooth power supplies by storing and releasing energy (e.g. after rectifiers in DC supplies).

- Block DC between amplifier stages while allowing AC signals to pass (coupling caps).

While film or ceramic capacitors can sometimes be used instead, they are usually larger or limited in capacitance compared with electrolytic (polarized) capacitors.

Why use non-polarized capacitors?

Non-polarized capacitors offer several advantages:

- They typically have lower leakage current than electrolytic capacitors.

- They can be used with AC signals or DC in either direction, since they don’t have a required polarity.

- Their capacitance value remains stable regardless of which side is at a higher potential (no polarity-sensitivity in normal use).

They’re ideal in signal paths, AC circuits, filters, and timing networks where the voltage may reverse.

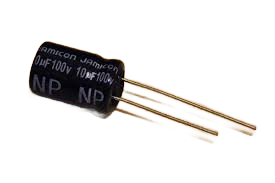

What is an example of a polarized capacitor?

Common examples of polarized capacitors include:

These devices have clearly marked positive and negative terminals and must be connected the right way around in a circuit. Current is intended to flow with a defined polarity across them; reversing that polarity can damage the capacitor.

Where are polarized capacitors used?

Polarized capacitors are widely used in:

- Power supply filtering – to smooth out voltage ripple and reduce fluctuations.

- Energy storage – they hold more energy than many non-polarized types of similar size, so they’re used wherever bulk capacitance is needed.

- Noise filtering – in many electronic devices, they help reduce electrical noise on power rails or signal lines.

Subscribe to JMBom Electronics !