Radial vs Axial Capacitor

Catalog

What Are Radial Capacitors?What Is an Axial Capacitor?Radial vs Axial CapacitorsEquivalent Series Inductance (ESL)Can I Replace an Axial Capacitor with a Radial One?Capacitors: What Types Are There?Final ThoughtsFrequently Ask QuestionsWhat Are Radial Capacitors?

In an electrolytic capacitor, the leads usually come out from one end of the body. With a radial capacitor, both leads exit from the same side, and they are typically thicker and more robust. Radial capacitors are very common in designs where you need high capacitance at a relatively low cost.

Structurally, they are polarised components, with a clearly marked positive and negative terminal. Thanks to their compact, upright form factor, they work well in both through-hole and certain surface-mount style layouts, making them suitable for many types of PCB assembly.

In aluminium electrolytic radial capacitors, an aluminium foil, soaked in electrolyte, forms the cathode, while another aluminium foil with an oxide layer acts as the anode (electrode). This structure allows them to store a large amount of charge in a relatively small package.

Among the various capacitor types available, radial electrolytic capacitors are generally some of the most widely used in everyday electronic circuits.

What Is an Axial Capacitor?

Axial capacitors are a type of leaded capacitor where the leads (wires) come out from both ends of the cylindrical body. In other words, one lead is on each side, so the capacitor looks a bit like a small tube with a wire sticking out of each end. These leads are usually straight and can be easily inserted into circuit boards or wired into point-to-point assemblies.

When installing axial capacitors in an electrical circuit, it’s important to connect the leads to the correct points according to the circuit design. Their shape makes them very convenient for layouts where the component needs to lie flat along the board or fit neatly in tight spaces.

Axial capacitors are available in a wide range of capacitance and voltage ratings, so they can be used in many different applications, from general electronics to more specialised equipment.

Note: The choice between radial and axial capacitors depends on your specific application. Factors such as available space, mounting style, electrical requirements, and budget should all be considered to help you decide which type is the best fit.

Radial vs Axial Capacitors

1. Configuration

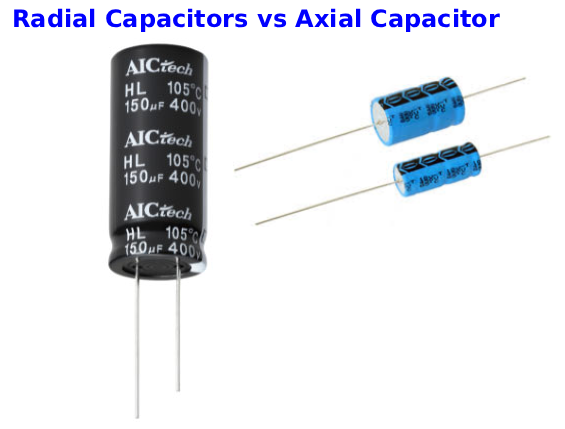

Radial capacitors are usually mounted upright on the PCB and have a cylindrical body. Both of their leads come out from the same end, so when you look closely, you’ll see the two leads exiting from the bottom of the capacitor. This is why radial capacitors are typically installed in a vertical position on the board.

Axial capacitors, by contrast, have one lead at each end of the cylinder. The body lies more like a horizontal cylinder, with the leads extending along its axis. This shape makes them ideal for laying flat across the board or along wiring runs.

In any circuit, it’s generally good practice to keep lead lengths as short as possible, especially at high-impedance nodes, to reduce noise and unwanted interference.

2. Physical Dimensions

There isn’t a strict, universal rule separating radial and axial capacitors by size, but there are typical trends in their dimensions.

- Radial capacitors Tend to be shorter and wider Commonly seen in compact PCB designs Often used where vertical space is available but footprint area must be kept small

- Axial capacitors Usually narrower and longer Designed to lie flat and span a distance on the board or within wiring Handy in layouts where components need to be in line with the wiring path

Remember that capacitor size is largely determined by its capacitance value and voltage rating (its energy-handling capability), not just the lead style.

Understanding these physical characteristics is important when designing or repairing circuits. For PCB-based designs, you need to make sure the capacitor’s shape, height, and lead arrangement match the available space and pad layout. Depending on the circuit requirements and the desired layout, either a radial or an axial capacitor may be the better choice.

Leads

Another key difference between radial and axial capacitors is the way their leads are arranged.

On a radial capacitor, both leads come out from the same side of the body and are spaced apart so they can easily be inserted into holes on a PCB. The body itself is not connected along its length to any other lead point; the connections are made only where the leads exit the package.

With an axial capacitor, one lead comes out of each end of the cylindrical body, running in a straight line along its axis. This makes it easy to mount the capacitor lying flat, or to connect it in-line between two points on the PCB or in wiring.

Price

If you’re choosing between radial and axial capacitors, cost is another practical factor.

In general, radial capacitors tend to be cheaper and more widely available than axial types. Axial capacitors are often more expensive due to lower production volumes and more specialised use. Prices for both types will also vary depending on:

- Capacitance and voltage rating

- Brand and quality

- Where you buy them (supplier, region, quantity, etc.)

Equivalent Series Inductance (ESL)

When selecting any capacitor, it’s important to consider its equivalent series inductance (ESL), which represents the small amount of inductance the capacitor effectively adds to the circuit.

In many cases, radial capacitors offer lower ESL than comparable axial capacitors. This can be beneficial in applications where:

- High frequencies are involved

- You need stable performance with minimal impedance changes

- Fast transient response or low noise is important

Lower ESL generally means better performance at higher frequencies.

Can I Replace an Axial Capacitor with a Radial One?

In recent years, manufacturers have focused more on producing radial capacitors, so they are now much more common. Many older devices, however, were originally designed with axial capacitors. As a result, high-quality axial replacements can be harder to find and more expensive.

Because of this, it’s increasingly common to replace axial capacitors with radial ones by adapting the mounting. This usually involves:

- Using a radial capacitor with suitable capacitance and voltage ratings

- Bending and extending the leads so it can reach the original axial connection points

However, be aware that extending the leads of a radial capacitor can slightly affect its performance:

- At higher frequencies, the impedance can change due to the added lead inductance

- The effective ESR (equivalent series resistance) may increase slightly

In most low-frequency or general-purpose applications, this small change is acceptable. But in sensitive, high-frequency, or precision circuits, you should check the design requirements carefully before substituting an axial capacitor with a radial one.

Capacitors: What Types Are There?

Capacitors come in several main types, including ceramic, electrolytic, film, and paper capacitors.

- Ceramic capacitors These are among the most commonly used dielectric capacitors in modern electronics. They use a ceramic material as the dielectric and are widely used because they are compact, reliable, and suitable for high-frequency applications.

- Film capacitors Film capacitors use a thin plastic film as the dielectric. They typically offer a long service life, good stability, and are relatively cost-effective, making them popular in many general-purpose and power applications.

- Electrolytic capacitors In electrolytic capacitors, the anode is made of metal (such as aluminium) and covered with a thin, oxidised dielectric layer. They provide high capacitance values in a relatively small package, which is why they’re often used in power supplies and smoothing circuits.

- Paper capacitors Paper capacitors use paper impregnated with a dielectric material as their insulating layer. While they are less common in modern designs, they were widely used in older equipment and can still be found in some specialised or legacy applications.

Final Thoughts

In summary, both radial and axial capacitors have an elongated cylindrical (or similar) body, but their lead arrangement and mounting style are different:

- A radial capacitor has both leads exiting from one end, and is usually mounted vertically on the PCB.

- An axial capacitor has one lead at each end, and is typically mounted horizontally, lying along the board or within wiring.

Both types are widely used in electronic circuits, but often in different roles:

- Radial capacitors are very common in power supplies, filtering, and general PCB-based designs.

- Axial capacitors are frequently used in RF circuits, audio gear, and vintage or point-to-point wired equipment, where their shape and lead style make routing easier.

Hopefully this FAQ has cleared up the differences between radial vs axial capacitors and helped you decide which is more suitable for your design.

Frequently Ask Questions

How are axial and radial components different?

Through-hole components are generally grouped into two styles: axial and radial leaded components.

- Axial components have one lead at each end of the body, so the leads run in a straight line along the axis of the component.

- Radial components have both leads coming out from the same side (usually the bottom) of the body.

This difference mainly affects how the component is mounted and oriented on the PCB.

Which is better: radial or axial?

Neither type is universally “better” – it depends on your application and layout:

- Radial capacitors are very common, compact, and easy to place on modern PCBs. They’re often preferred in power supplies, general-purpose circuits, and high-density boards.

- Axial capacitors are easier to mount lying flat or in-line with wiring, so they’re useful in point-to-point wiring, vintage equipment, or where mechanical layout requires a long, inline component.

Your choice should be based on mechanical fit, PCB design, required performance, and cost, not just the lead style.

Do axial capacitors have polarity?

Some axial capacitors are polarised, and some are non-polarised, depending on the type:

- Axial electrolytic capacitors are usually polarised. They often have: A band or stripe marking the negative terminal, or Arrows pointing toward the negative lead, or A marking (such as a “+”) at the positive end.

- Axial film or paper capacitors are typically non-polarised and can be connected either way round in the circuit.

Always check the markings on the body and the datasheet to confirm polarity before installation.

Subscribe to JMBom Electronics !