SP-Cap: Conductive Polymer Aluminum Electrolytic Capacitors

Catalog

Unmatched Core Features of SP-CapSP-Cap: Solving Industry-Wide Capacitor ChallengesVersatile Applications: Powering the Future of ElectronicsSource Your SP-Cap from jmbom.com: Your Trusted Component PartnerConclusionIn the fast-paced world of electronics, where precision, reliability, and miniaturization are non-negotiable, the choice of capacitors can make or break the performance of a device. From server CPUs handling massive data loads to compact mobile devices and high-end graphics cards, every component relies on stable power delivery and effective noise suppression. Enter SP-Cap—conductive polymer aluminum electrolytic capacitors that redefine industry standards with their exceptional performance, robust safety features, and versatile applications. More than just a component, SP-Cap is a game-changer designed to solve the most pressing challenges faced by engineers and manufacturers when using traditional electrolytic or tantalum capacitors.

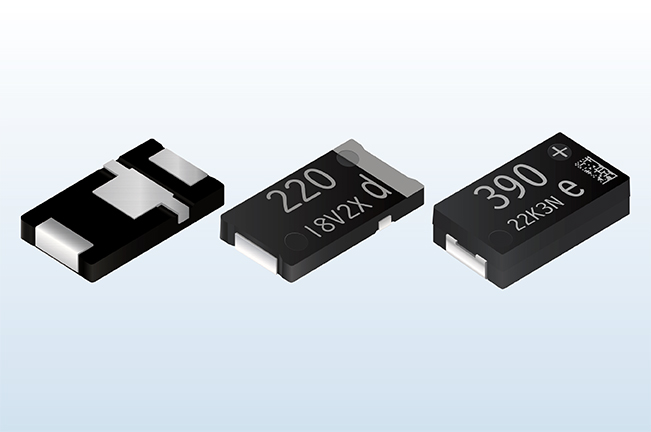

Conductive Polymer Aluminum Electrolytic Capacitors

At its core, SP-Cap is a rectangular chip-shaped aluminum electrolytic capacitor that leverages advanced polymer electrolytes to deliver superior electrical characteristics. Unlike conventional capacitors that rely on liquid electrolytes, SP-Cap’s polymer-based design eliminates common pain points such as leakage, instability, and limited lifespan. This innovative construction grants it a suite of standout features: ultra-low equivalent series resistance (ESR), minimal equivalent series inductance (ESL), extended operational life, compact form factor, ultra-low profile, and unrivaled characteristic stability across extreme conditions. For industries pushing the boundaries of performance—from data centers to consumer electronics—SP-Cap is not just an upgrade; it’s a necessity.

Unmatched Core Features of SP-Cap

SP-Cap’s dominance in the market stems from its carefully engineered features that address the evolving needs of modern electronics. Let’s break down what makes these capacitors a cut above the rest:

Ultra-Low ESR Performance: As a top-tier ultra-low ESR capacitor in the industry, SP-Cap excels in high-frequency applications. ESR directly impacts a capacitor’s ability to filter noise and deliver instantaneous current—critical for powering high-performance components like CPUs and GPUs. With ESR values that outperform traditional aluminum electrolytic and even some tantalum capacitors, SP-Cap ensures stable voltage regulation, reduces power loss, and enhances overall system efficiency. This is particularly vital in AI servers and high-performance computing (HPC) systems, where nanosecond-level load transients demand rapid energy delivery to prevent voltage sag and computational errors <superscript>1.

Stable Temperature and Frequency Characteristics: Unlike conventional capacitors whose performance degrades sharply under extreme temperatures, SP-Cap maintains consistent electrical properties from low to high temperature ranges. This stability is attributed to its conductive polymer electrolyte, which resists thermal breakdown and ensures reliable operation in harsh environments—from industrial control systems to automotive electronics. Additionally, SP-Cap’s frequency response remains flat across a wide spectrum, making it ideal for high-switching-frequency power supplies, including those using gallium nitride (GaN) semiconductors operating at 1MHz or higher <superscript>10.

Ultra-Low Profile Design: With a maximum thickness of just 1.0mm, SP-Cap’s low-profile lineup is tailored for space-constrained applications. As devices become increasingly compact—think slim laptops, wearable tech, and miniaturized industrial sensors—every millimeter counts. SP-Cap’s rectangular chip shape and thin form factor allow engineers to optimize PCB real estate without compromising performance, enabling sleeker, more powerful designs.

Enhanced Safety via Self-Recovery Function: Safety is paramount in electronic design, and SP-Cap sets a new standard with its self-recovery mechanism. Unlike tantalum capacitors, which are prone to ignition when short-circuited, or traditional aluminum electrolytic capacitors that may leak or burst, SP-Cap eliminates ignition risks entirely. Its self-recovery function repairs minor dielectric damage caused by voltage spikes or wear, preventing catastrophic failures and ensuring long-term system reliability. This feature is a critical advantage in mission-critical applications like medical devices and automotive electronics, where safety incidents can have severe consequences.

Low ESL Three-Terminal Structure: For applications requiring minimal inductance, SP-Cap offers a low ESL variant with a three-terminal structure. ESL contributes to signal interference and voltage overshoot in high-frequency circuits, so reducing it is essential for maintaining signal integrity. This design makes SP-Cap ideal for high-speed communication systems and FPGA power lines, where precise power delivery and noise suppression are critical.

SP-Cap: Solving Industry-Wide Capacitor Challenges

Traditional electrolytic capacitors and general tantalum capacitors are plagued by a range of issues that hinder performance, reliability, and safety. From noise interference to structural failures, these problems can lead to costly redesigns, product recalls, and compromised user experiences. SP-Cap is engineered to directly address these pain points, offering targeted solutions that no other capacitor technology can match. Below is a detailed breakdown of how SP-Cap solves the most common capacitor challenges:

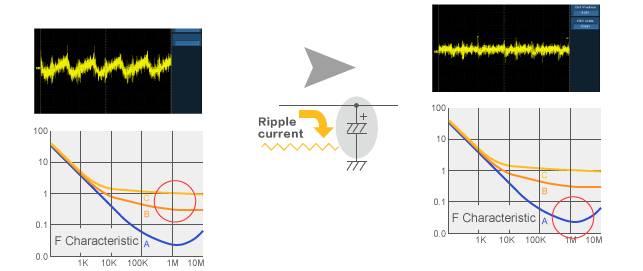

1. Noise Suppression: Taming High-Frequency Interference

High ripple by high ESR vs Low ripple by low ESR

General tantalum aluminum electrolytic capacitors vs Conductivity

High-frequency noise is a pervasive issue in modern electronics, especially in power supplies and high-speed signal paths. Traditional capacitors often fail to suppress MHz-range noise effectively, leading to signal degradation, system instability, and compliance issues with electromagnetic interference (EMI) standards. SP-Cap’s ultra-low ESR and stable frequency characteristics make it a superior noise filter. By absorbing and dissipating high-frequency noise before it propagates through the circuit, SP-Cap ensures clean power delivery to sensitive components like CPUs, GPUs, and FPGAs. In AI servers and graphics cards, this translates to smoother performance, reduced computational errors, and compliance with strict EMI regulations—eliminating the need for additional noise-suppression components and simplifying circuit design.

2. Ignition Prevention: Eliminating Catastrophic Failures

Overvoltage test General tantalum capacitors vs Overvoltage test Conductive capacitors

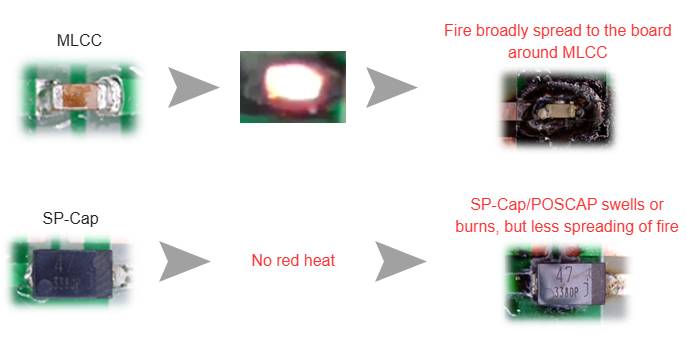

Tantalum capacitors are notorious for their ignition risk when subjected to overvoltage or short-circuit conditions. This not only destroys the capacitor but can also spread fire to the entire PCB, causing irreparable damage. Traditional aluminum electrolytic capacitors fare little better, with liquid electrolytes that may leak or burst under stress. SP-Cap’s self-recovery function and polymer electrolyte eliminate these risks entirely. The self-recovery mechanism repairs small dielectric defects, preventing short-circuits from escalating into fires. Unlike tantalum capacitors, there is no risk of ignition—even in extreme operating conditions. For applications where safety is non-negotiable, such as aerospace electronics, medical devices, and automotive systems, SP-Cap provides peace of mind that traditional capacitors cannot match.

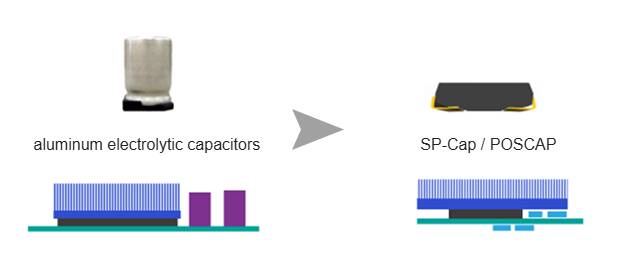

3. Low Profile & Space-Saving: Optimizing PCB Design

Low profile

Space-saving(Reduced space by 70%)

Measures

The drive toward miniaturization has put immense pressure on engineers to reduce component size without sacrificing performance. MLCCs (multi-layer ceramic capacitors) are often used for space-saving, but they come with their own limitations. SP-Cap’s 1.0mm max thickness and rectangular chip shape offer a superior alternative. It delivers higher capacitance density than MLCCs in a comparable footprint, allowing engineers to reduce the number of components on the PCB. This not only saves space but also cuts assembly costs and improves reliability by minimizing solder joints. Whether designing slim laptops, compact IoT sensors, or dense server motherboards, SP-Cap enables more efficient use of PCB real estate—unlocking new possibilities for device design.

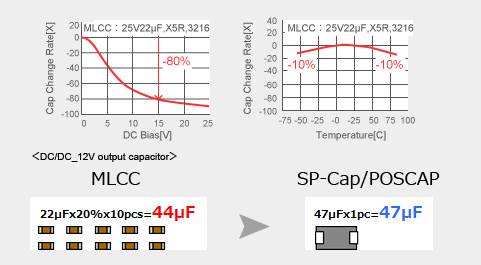

Insufficient capacitance Quantity/Cost reduction

- Capacitance of MLCC is reduced by Voltage application + Low temperature/High temperature

Squeaking / Micro vibration

Rudeness prevention

Anti-vibration

Cracks

Crack prevention measure

- MLCC is cracked by temperature/mechanical impact

Fire spreading to board

Safety measure

The red heat continues if MLCC is short-circuited.

4. Addressing MLCC Shortcomings: Capacitance, Vibration, Cracks, and Fire Spread

MLCCs are widely used in electronics, but their inherent flaws often require workarounds that add complexity and cost. SP-Cap solves these issues comprehensively:

Insufficient Capacitance & Cost Reduction: MLCC capacitance degrades significantly under voltage application and extreme temperatures (both low and high), forcing engineers to use multiple MLCCs in parallel to meet capacitance requirements. This increases component count, PCB space, and overall cost. SP-Cap maintains stable capacitance across voltage and temperature ranges, delivering higher effective capacitance in a single component. By replacing multiple MLCCs with a single SP-Cap, manufacturers can reduce part counts, lower assembly costs, and simplify supply chain management—all while improving performance. This is a game-changer for high-volume production, where even small cost savings per unit add up to significant margins.

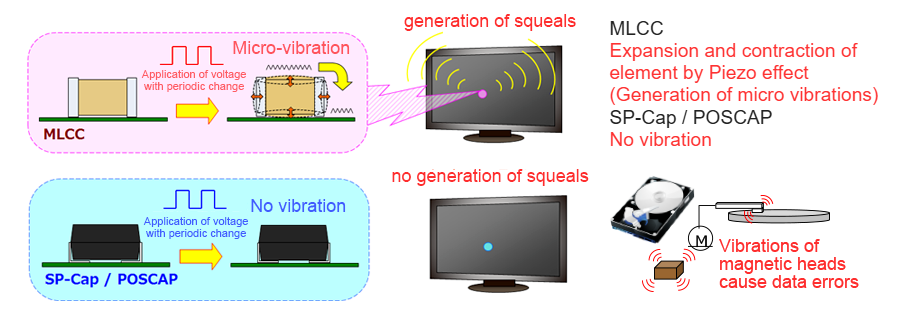

Squeaking & Micro-Vibration: MLCCs are prone to micro-vibrations (known as “squeaking”) caused by voltage fluctuations, which can generate audible noise and mechanical stress on the PCB. This is a common issue in consumer electronics like TVs and laptops, where user experience is paramount. SP-Cap’s polymer electrolyte and robust construction dampen micro-vibrations, eliminating squeaking and reducing mechanical stress on the circuit. This ensures quieter operation and extends the lifespan of the PCB by preventing vibration-induced wear.

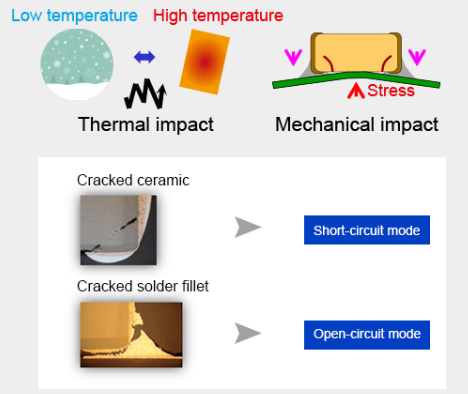

Crack Prevention: MLCCs are brittle and susceptible to cracking from temperature cycling and mechanical impact. Thermal expansion and contraction during operation, combined with handling during assembly, often lead to hidden cracks that cause premature failure. SP-Cap’s flexible polymer electrolyte and aluminum core absorb mechanical stress and temperature-induced expansion, reducing the risk of cracks. This makes SP-Cap ideal for rugged applications like industrial equipment, automotive electronics, and portable devices that are exposed to frequent shocks and temperature changes.

Preventing Fire Spread to the Board: When MLCCs short-circuit, they can continue to generate heat (red heat) and spread fire to adjacent components and the PCB. This is a critical safety hazard in enclosed devices like servers and consumer electronics. SP-Cap’s self-recovery function prevents sustained short-circuits, eliminating the risk of prolonged heat generation and fire spread. Even in the event of a severe fault, the polymer electrolyte does not ignite or leak, containing the issue to the capacitor itself and protecting the rest of the system.

Versatile Applications: Powering the Future of Electronics

SP-Cap’s exceptional performance and reliability make it suitable for a wide range of high-demand applications. Its low ESR is the primary driver for its use in power delivery circuits, where stable current and voltage regulation are critical. Below are the key application areas where SP-Cap excels:

CPU Power Lines: Servers, mobile PCs, and video game consoles rely on CPUs that demand instantaneous current delivery and stable voltage. SP-Cap’s ultra-low ESR and fast transient response ensure that CPUs receive consistent power, even during peak load conditions. In AI servers and HPC systems, this prevents voltage sag and computational errors, maximizing processing efficiency and uptime <superscript>1.

FPGA Power Lines: Communications and industrial FPGAs operate at high frequencies and require precise power regulation to maintain signal integrity. SP-Cap’s low ESL three-terminal structure and stable frequency characteristics make it ideal for FPGA power circuits, reducing noise and ensuring reliable data transmission. This is critical in industrial control systems, where downtime can lead to costly production losses.

GPU Power Lines: Graphics cards generate massive amounts of heat and demand high current for intensive tasks like gaming and 3D rendering. SP-Cap’s thermal stability and low ESR ensure that GPUs receive consistent power, preventing overheating and performance throttling. This delivers smoother gaming experiences and faster rendering times for professionals.

Other Applications: Beyond power delivery circuits, SP-Cap is widely used in LCD panels, where its low profile and stable performance ensure consistent backlighting and image quality. It also finds applications in IoT devices, wearable tech, automotive electronics, and medical devices—anywhere reliability, miniaturization, and safety are critical.

LCD panels

Source Your SP-Cap from jmbom.com: Your Trusted Component Partner

When it comes to sourcing high-quality SP-Cap conductive polymer aluminum electrolytic capacitors, jmbom.com is your one-stop solution. As a leading supplier of electronic components, jmbom.com offers a comprehensive lineup of SP-Cap products, including ultra-low profile, low ESL, and high-temperature variants to meet your specific design needs. Whether you’re designing a next-generation server, a compact mobile device, or a rugged industrial system, jmbom.com provides genuine, reliable SP-Cap capacitors backed by strict quality control and competitive pricing.

At jmbom.com, we understand that every project has unique requirements. Our team of technical experts is ready to assist you in selecting the right SP-Cap model for your application, ensuring optimal performance and cost-efficiency. We offer flexible ordering options, fast shipping, and dedicated customer support to streamline your procurement process. Don’t let capacitor limitations hold back your design—partner with jmbom.com to access the industry’s best SP-Cap solutions.

Ready to elevate your electronics with SP-Cap? Visit jmbom.com today to browse our SP-Cap product range and submit an inquiry. Our team will respond promptly with detailed specifications, pricing, and availability, helping you bring your innovative designs to life.

Conclusion

SP-Cap conductive polymer aluminum electrolytic capacitors represent the pinnacle of capacitor technology, offering unmatched performance, reliability, and safety for modern electronics. From solving MLCC and tantalum capacitor shortcomings to enabling miniaturized, high-performance designs, SP-Cap is the go-to choice for engineers and manufacturers worldwide. Its ultra-low ESR, stable temperature characteristics, self-recovery safety feature, and compact form factor make it indispensable in applications ranging from AI servers to consumer electronics.

To unlock the full potential of your designs, source your SP-Cap from jmbom.com—the trusted supplier of high-quality electronic components. With a comprehensive product lineup, technical expertise, and exceptional customer service, jmbom.com ensures that you get the right components at the right time, every time. Don’t compromise on performance or safety—choose SP-Cap and jmbom.com for your next project.

Subscribe to JMBom Electronics !