What are Aluminum Electrolytic Capacitors?

Catalog

Overview of Aluminum Electrolytic CapacitorsWhat are Aluminum Electrolytic Capacitors?Construction of Aluminum Electrolytic CapacitorsElectrical Characteristics of Aluminum Electrolytic CapacitorsWorking Principle of Aluminum Electrolytic CapacitorsAdvantages and Disadvantages of Aluminum Electrolytic CapacitorsApplications of Aluminum Electrolytic CapacitorsConductive Polymer Hybrid Aluminum Electrolytic CapacitorsFrequently Ask QuestionsRelated ArticlesOverview of Aluminum Electrolytic Capacitors

Aluminum Electrolytic Capacitors

Aluminum electrolytic capacitors are a type of capacitor that uses an aluminum oxide dielectric material, which is formed chemically on the surface of the aluminum conductive material. They are widely used in various electronic devices and circuits due to their high capacitance values and ability to handle large amounts of current.

What are Aluminum Electrolytic Capacitors?

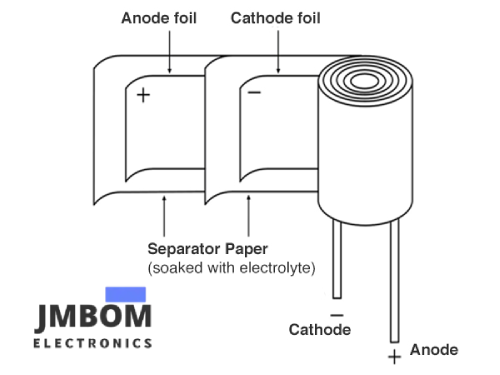

Aluminum Electrolytic Capacitors are a category of polarized capacitors utilizing aluminum for the electrode material. They are extensively utilized in electronic circuits because of their high capacitance and cost-effectiveness. These capacitors are wound types, consisting of two aluminum foils—an anode and a cathode—separated by a paper spacer soaked in a liquid or gel electrolyte. The anode and cathode foils are etched to expand their surface area, which enhances capacitance. Applying a positive voltage to the anode forms an insulating oxide layer, whose thickness matches the applied voltage. This oxide layer serves as the dielectric in the capacitor. A separator, a non-conductive material, prevents electrical contact between the anode and cathode while permitting ion movement.

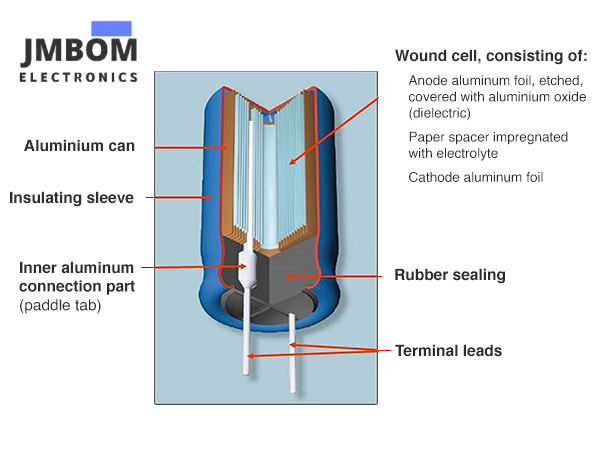

Construction of Aluminum Electrolytic Capacitors

construction of an electrolytic capacitor

The construction of an electrolytic capacitor uses two thin aluminum foil layers: one plain and one etched. These foils are separated by an electrolyte. To create polarity, the aluminum oxide layer is chemically grown on one foil (the anode), which makes it distinct from the cathode. During the construction process, you get an anodized anode and a cathode, with an electrolyte-soaked paper acting as the separator.

When the capacitor is working normally, the anode is positive, and the cathode is negative (marked with a "-" on the body). Since aluminum capacitors are polarized, applying voltage the wrong way (reverse polarity) can mess with the insulation and damage the capacitor.

One cool thing about aluminum capacitors is their self-healing ability. If the capacitor gets damaged by reverse voltage, the oxide layer can break down, but it still lets current flow between the foils.

Electrical Characteristics of Aluminum Electrolytic Capacitors

Capacitance (C): This parameter quantifies the capacitor's capacity to store electrical charge relative to the applied voltage. Aluminum electrolytic capacitors typically offer capacitance values from several microfarads up to thousands of microfarads. Capacitance tends to rise with increasing temperature and fall with higher operating frequencies.

Equivalent Series Resistance (RESR): The ESR in an Aluminum Electrolytic Capacitor reflects the internal resistance that leads to power dissipation and heat generation within the component. Primarily influenced by the electrolyte's resistance, ESR generally decreases as the temperature rises. Common ESR values span from a few milliohms (mΩ) to several ohms.

Rated Voltage (Vrated): This is the highest voltage at which the capacitor can be continuously operated without risking failure. Aluminum electrolytic capacitors are available with rated voltages ranging from 6.3V to 450V, tailored to specific applications and design requirements.

Equivalent Series Inductance (LESL): LESL denotes the effective self-inductance inherent to the aluminum electrolytic capacitor, influencing its performance at high frequencies.

Leakage Current (Ileakage): Even when the capacitor is charged and not connected to an external load, a small amount of current, known as leakage current, passes through it. Minimizing leakage current is crucial for enhancing energy efficiency and extending the capacitor's lifespan. Leakage current values usually range from a few microamperes (µA) to several milliamperes (mA), depending on the capacitor's dimensions and voltage rating.

Aluminum electrolytic capacitors find widespread use across numerous industries due to their advantageous blend of high capacitance, reasonable energy density, and robust voltage capabilities. They are commonly employed in applications such as power supply filtering, energy storage systems, automotive electronics, consumer devices, backup power solutions, and industrial machinery.

Working Principle of Aluminum Electrolytic Capacitors

Capacitance is determined by the surface area of the aluminum foils and the thickness of the dielectric layer.When a voltage is applied across the terminals of the capacitor, an electric field is established, and the capacitor stores charge.

Advantages and Disadvantages of Aluminum Electrolytic Capacitors

Advantages

High Capacitance: They can provide high capacitance values in a relatively small package.High Voltage Tolerance: They can handle high voltages, making them suitable for power supply filtering and smoothing applications.Large Current Handling: They are capable of handling large amounts of current, which is beneficial in power circuits.

Disadvantages

Leakage Current: They have a higher leakage current compared to other types of capacitors, which can lead to self-discharge over time.Limited Lifespan: They have a finite lifespan, which can be affected by temperature, voltage, and the quality of the electrolyte.Size and Weight: They are generally larger and heavier than other capacitor types, such as ceramic or film capacitors.

Applications of Aluminum Electrolytic Capacitors

Power Supplies: Used for filtering and smoothing in power supply circuits.Audio Equipment: Employed in amplifiers and other audio devices for coupling and decoupling.Electrical Machinery: Used in motor start circuits and for energy storage in large industrial applications.Automotive: Found in automotive electronics for power storage and filtering.

Boost Performance with Superior Quality

Panasonic has designed capacitors to maximize both performance and durability. As a leading supplier of passive components, Panasonic produces aluminum electrolytic capacitors in both surface-mount and radial-lead types. See for yourself how Panasonic aluminum electrolytic capacitors can transform your circuit design!

Conductive Polymer Hybrid Aluminum Electrolytic Capacitors

Durable and Ripple-Current Resistant

Panasonic's hybrid capacitors blend the best features of aluminum electrolytic and specialty polymer capacitors. They offer high durability, low ESR, exceptional ripple current resistance, surge current endurance, and superior performance at high temperatures. Known for stable electrical characteristics at high frequencies, these hybrid capacitors maximize reliability. Their compact design saves PCB space, and they even come with anti-vibration features.

Ideal MLCC Replacements

Panasonic hybrid capacitors combine the strengths of aluminum electrolytic and specialty polymer types, providing high durability, low ESR, and excellent ripple/high-frequency current handling. These qualities make them a great alternative to MLCCs, especially with their compact, vibration-resistant designs.

Recommended MLCC Alternatives

The hybrid capacitor lineup includes several MLCC replacement series, such as EEH-ZA, EEH-ZC, EEH-ZE, EEH-ZK, EEH-ZS, and EEH-ZF.

Aluminum Electrolytic Capacitors (Surface-Mount Type)

As a global leader in capacitor technology, Panasonic offers an extensive range of surface-mount aluminum electrolytic capacitors. These capacitors are renowned for their high reliability, long lifespan, low impedance, and high ripple current capability. With 30 series available, Panasonic SMT capacitors fit a wide range of applications.

Panasonic has expanded 12 of its SMT aluminum electrolytic capacitor series to include various anti-vibration parts that can withstand up to 30G! These new SMT anti-vibration capacitors meet AEC-Q200 standards, making them ideal for automotive and other harsh environments, ensuring top-tier quality and reliability.

Aluminum Electrolytic Capacitors (Radial Lead Type)

Designed for high reliability, long life, low impedance, and high ripple current performance.

Frequently Ask Questions

What are aluminum electrolytic capacitors used for?

Aluminum electrolytic capacitors are mainly found in power supplies and DC-DC converters. They help smooth out and buffer rectified DC voltages in electronic devices. You’ll also see them used in industrial power systems. They’re polarized, meaning they have a specific positive and negative side, thanks to how they’re made (anodization).

How long does an aluminum electrolytic capacitor last?

Manufacturers usually rate their lifetimes based on the highest ambient temperature (often 105°C). Lifetimes can range anywhere from 1,000 hours to over 10,000 hours, depending on the design.

How do aluminum electrolytic capacitors fail?

These capacitors are sometimes called chemical capacitors because they rely on chemical reactions to work. Their performance is highly sensitive to things like temperature and environmental conditions. If things go south (like rapid chemical reactions), they can fail.

How do I dispose of electrolytic capacitors near me?

Don’t just toss capacitors into regular trash bins! Look for electronic waste recycling programs or hazardous waste facilities in your area. These places can handle and recycle components safely.

Why are electrolytic capacitors still used?

They’re super important in telecom equipment, like routers and modems. They help with signal filtering, reduce noise, and make sure communication stays reliable.

What are the two common faults in electrolytic capacitors?

The two main issues are:

Sudden, catastrophic failures caused by manufacturing problems or incorrect use.

Wear-out faults over time, which are just part of the capacitor's lifespan.

Can I throw a capacitor in the garbage?

Nope! Instead, give them to a licensed industrial waste contractor. They’ll take care of proper disposal through incineration or landfill methods.

Can capacitors last 40 years?

Yep, it’s possible! If a capacitor is kept cool, it could last 40 years. But watch out for higher ESR (equivalent series resistance) as the electrolyte dries out. It’s not a dramatic failure, but eventually, the circuit might stop working properly.

Related Articles

Film Capacitors:Features,Types,and Applications

Power Inductors for Automotive Applications

Subscribe to JMBom Electronics !