What Induction Motor Is and How It works

Catalog

What is an Induction Motor?How an Induction Motor WorksTypes of Induction MotorsWhy is a Three Phase Induction Motor Self-Starting?Working Principle of a Three Phase Induction Motor Frequently Ask QuestionsWhat is an Induction Motor?

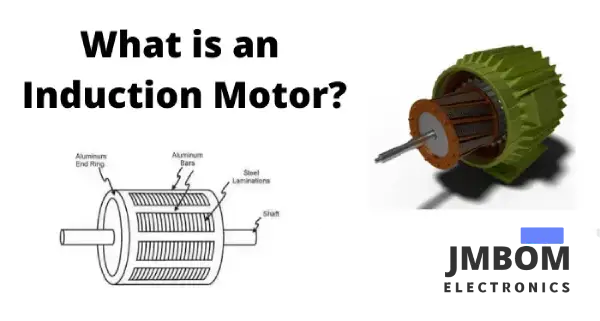

An induction motor (sometimes called an asynchronous motor) is a super common type of AC electric motor. The way it works is pretty cool—basically, the electric current that’s needed in the rotor to produce torque comes from electromagnetic induction, thanks to the rotating magnetic field in the stator winding. The rotor itself can either be a squirrel cage type or a wound type.

Now, induction motors are called ‘asynchronous’ because they run at a speed that's a bit less than their synchronous speed. But, wait—what exactly is synchronous speed? Let’s break that down first.

AC electric motor

Synchronous Speed

Synchronous speed is basically the speed at which the magnetic field rotates in a rotary machine. How fast that happens depends on the frequency and the number of poles in the machine. Now, an induction motor will always run a bit slower than this synchronous speed.

What happens is that the rotating magnetic field in the stator creates a flux in the rotor, which makes the rotor spin. But here’s the thing—because of a lag between the flux in the rotor and the flux in the stator, the rotor can never quite catch up to the speed of the rotating magnetic field (which is the synchronous speed).

Induction motors come in two types based on the input power: single phase and three phase. Single phase motors can’t start on their own, but three phase motors are self-starting.

How an Induction Motor Works

To get a DC motor to spin, we have to give it two different supplies—one to the stator and one to the rotor (using brushes). But with an induction motor, we only give it one supply, so how does it actually work? Well, it’s pretty cool.

As the name suggests, induction is the key here. When we power up the stator winding, it creates a magnetic flux because the current flows through the coil. Now, the rotor winding is set up so that each coil is short-circuited.

This flux from the stator cuts across the short-circuited coils in the rotor. And because those rotor coils are short-circuited, according to Faraday’s law of electromagnetic induction, a current starts flowing through the rotor coils. As the current flows, it creates its own flux in the rotor.

Now we have two fluxes—one from the stator and one from the rotor. The rotor’s flux will lag behind the stator’s flux. Because of this lag, the rotor experiences a torque that makes it spin in the direction of the rotating magnetic field. This is how both single-phase and three-phase induction motors work.

Types of Induction Motors

Induction motors can be grouped based on whether they’re single phase or three phase.

Single Phase Induction Motor

Some types of single phase induction motors are:

- Split Phase Induction Motor

- Capacitor Start Induction Motor

- Capacitor Start and Capacitor Run Induction Motor

- Shaded Pole Induction Motor

- Three Phase Induction Motor

For three phase induction motors, the main types are:

- Squirrel Cage Induction Motor

- Slip Ring Induction Motor

We’ve already talked about how single-phase induction motors aren’t self-starting, while three-phase induction motors are self-starting. So, what does “self-starting” really mean?

A self-starting motor is one that begins to run on its own without needing any extra force. For example, when you flip the switch for a fan, it starts spinning automatically, which makes it a self-starting machine.

But here’s something interesting: the fan we use at home is a single-phase induction motor, and it’s not inherently self-starting. So, you might wonder how it actually works. Let’s dive into that!

Why is a Three Phase Induction Motor Self-Starting?

In a three-phase system, there are three single-phase lines spaced out by 120°. This phase difference creates a rotating magnetic field that helps the rotor move.

Let’s break it down: you have three phases—let’s call them a, b, and c. When phase a starts magnetizing, it pulls the rotor. Then, a bit later, phases b and c magnetize in sequence, pulling the rotor along each time. This back-and-forth keeps the rotor spinning smoothly.

Working Principle of a Three Phase Induction Motor

Why Isn’t a Single Phase Induction Motor Self-Starting?

So, a single-phase induction motor has just one phase, but it can still get the rotor to rotate, which is pretty interesting. But first, we need to figure out why it’s not self-starting and how we can solve this issue. We know that the AC supply is a sinusoidal wave, and it creates a pulsating magnetic field in the evenly spread stator winding.

If we think of this pulsating magnetic field as two opposite rotating fields, there won’t be any net torque at the start, which means the motor won’t run. However, if we give the rotor a little push in either direction using an external force after powering it up, the motor will start running.

To tackle this problem, we can set up the stator winding with two windings—one main winding and one auxiliary winding. We then connect a capacitor in series with the auxiliary winding. This capacitor creates a phase difference when the current flows through both coils. With that phase difference, the rotor gets a starting torque and begins to spin.

In real life, if you disconnect the capacitor from a fan with a single-phase induction motor, it won’t start. But if you give the fan a manual spin, it will kick into action, showing just how important the capacitor is for starting the motor.

Induction motors have a lot of advantages, which is why they’re used in so many applications. One of their biggest perks is their high efficiency, which can reach up to 97%! However, a downside is that the motor’s speed can change based on the load applied.

For a three-phase induction motor, you can reverse its rotation direction by changing the phase sequence of the supply. For instance, switch it from RYB to RBY. But with single-phase motors, you can reverse the direction by just switching the capacitor terminals.

Frequently Ask Questions

What is the difference between an induction motor and a normal motor?

Alternative:

What distinguishes an induction motor from a conventional motor?

The fundamental difference between these two motors is that the speed of the rotor relative to the speed of the stator is equal for synchronous motors, while the rotor speed in induction motors is less than its synchronous speed. This is why induction motors are also known as asynchronous motors.

Alternative:

The key distinction between these two types of motors lies in the fact that synchronous motors have a rotor speed that matches the stator speed, whereas induction motors operate with a rotor speed that is lower than their synchronous speed, which is why they are referred to as asynchronous motors.

Why does Tesla use an induction motor?

Alternative:

What are the reasons behind Tesla's choice of induction motors?

One of the main reasons Tesla continues to use induction motors is their lower cost and the fact that they do not require permanent magnets, thereby avoiding the risk of demagnetization. First, induction motors do not need any permanent magnetic materials, which is particularly important in motor design.

Alternative:

A primary reason Tesla opts for induction motors is their cost-effectiveness and the absence of permanent magnets, which eliminates the risk of demagnetization. Importantly, induction motors do not rely on permanent magnetic materials, a crucial factor in motor design.

What is the principle of induction motor?

Alternative:

How does an induction motor operate?

The motor which works on the principle of electromagnetic induction is known as the induction motor. The electromagnetic induction is the phenomenon in which the electromotive force induces across the electrical conductor when it is placed in a rotating magnetic field.

Alternative:

An induction motor operates based on the principle of electromagnetic induction, where an electromotive force is induced in an electrical conductor when it is subjected to a rotating magnetic field.

Why do we use induction motor instead of DC motor?

Alternative:

What are the advantages of using an induction motor over a DC motor?

Induction motors require less maintenance as brushes and commutators are absent. DC motors require excessive maintenance due to the presence of brushes and commutators. Induction motors are required where there is a need for high speed and variable torque.

Alternative:

Induction motors are preferred over DC motors because they require less maintenance, as they do not have brushes and commutators. In contrast, DC motors need frequent maintenance due to these components. Additionally, induction motors are ideal for applications requiring high speed and variable torque.

Why is induction so popular?

Alternative:

What makes induction so widely used?

They know that it is suggested when it is felt that it would be safer for the baby to be born than to stay inside its mother. Many people also know that one of the main reasons for recommending induction of labour is because pregnancy has lasted for a certain number of weeks and the baby is perceived to be 'overdue.

Alternative:

It is commonly understood that induction is recommended when it is deemed safer for the baby to be delivered rather than remaining in the womb. Additionally, many are aware that one of the primary reasons for inducing labor is when a pregnancy extends beyond a certain number of weeks, and the baby is considered 'overdue.

Subscribe to JMBom Electronics !