Guide to Piezoelectric Actuator

Catalog

What Is a Piezoelectric Actuator?Piezoelectric Actuator Working Principle Features of Piezoelectric Actuators The Benefits of Piezoelectric Actuators Applications of Piezoelectric Actuators Frequently Asked QuestionsRelated ArticlesWhat Is a Piezoelectric Actuator?

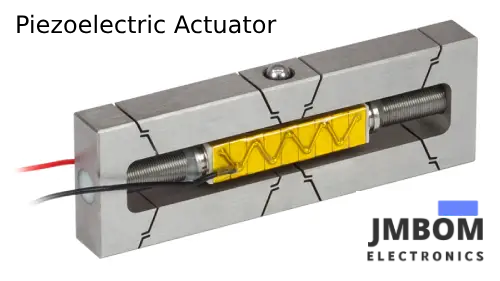

A Piezoelectric Actuator is a device that converts electrical energy into precise mechanical motion through the piezoelectric effect, which is a property of certain materials that generate an electric charge in response to applied mechanical stress. This actuator operates on the principle of electromechanical coupling rather than electromagnetic induction. When the actuator is not producing a stroke, it can store energy. The fine control over movement that these actuators offer is typically utilized for the minute adjustment of tools, optical components like mirrors and lenses, and other similar devices. Compared to their electromagnetic counterparts, piezoelectric actuators are known for their adaptable design, compactness, and ability to achieve positioning accuracy at the sub-micrometer or nanometer level.

Piezo actuators are also employed to regulate hydraulic valves, functioning akin to specialized motors, miniature pumps, and in various applications that require force or motion. The diagram illustrating the operation of a piezoelectric actuator is presented below.

What is a Piezoelectric Actuator?

Piezoelectric Actuator Working Principle

1. Piezoelectric Effect: This is a characteristic of certain materials, such as specific ceramics and crystals, which can generate an electric charge when subjected to mechanical stress. The same is true in reverse; when these materials are subjected to an electric field, they undergo mechanical deformation.

2.Direct Piezoelectric Effect: This refers to the creation of an electric charge in response to mechanical stress applied to piezoelectric materials. It is used in devices like sensors and microphones to convert mechanical vibrations into electrical signals.

3. Converse Piezoelectric Effect: This is the process where a piezoelectric material deforms when an electric field is applied to it. Actuators use this effect to convert electrical signals into mechanical motion.

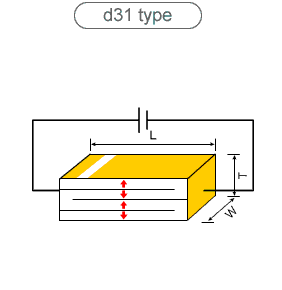

4. Operation of Piezoelectric Actuators: When a voltage is applied to a piezoelectric material, it changes shape, usually expanding in one dimension and contracting in another. This shape change enables the actuator to move or exert force. The degree of displacement is proportional to the voltage applied, allowing for precise control over the actuator's movement by adjusting the voltage.

5. Stacked Elements: To achieve greater displacement, piezoelectric actuators often incorporate multiple layers of piezoelectric material. These layers, when stacked, create a cumulative effect that results in a larger overall displacement.

Piezoelectric Actuator Working Principle

Features of Piezoelectric Actuators

1. High Precision: Piezoelectric actuators are capable of achieving extremely fine control over positioning, with resolutions that can reach into the nanometer range. This precision is vital for applications that require meticulous movement control.

2. Fast Response Time: These actuators have quick response times, which is essential for tasks that demand swift adjustments or rapid operation.

3. Large Bandwidth: They can function across a broad frequency spectrum, making them appropriate for applications that involve high-frequency motion.

4. High Force-to-Size Ratio: Despite their compact size, piezoelectric actuators can produce substantial force. This characteristic is advantageous for applications where space is at a premium but significant force is needed.

5. Non-magnetic: Piezoelectric actuators neither create nor are affected by magnetic fields, which is beneficial in environments where magnetic interference could be problematic.

6. Low Power Consumption: They operate with relatively low power requirements, which can be advantageous in applications where energy efficiency is a priority.

7. High Stiffness: Piezoelectric actuators have high mechanical stiffness, which helps to preserve positioning accuracy even when under load.

8. Long Lifespan: Their solid-state construction and lack of moving parts contribute to a long service life and high reliability.

Piezoelectric actuators

The Benefits of Piezoelectric Actuators

1. High Precision: Piezoelectric actuators can achieve nanometer-level precision, which is essential for applications that require meticulous control over positioning.

2. Fast Response: These actuators have a quick response time, making them ideal for applications that need rapid adjustments or operate at high speeds.

3. High Force-to-Size Ratio: Despite their small size, piezoelectric actuators can exert considerable force, offering a high force-to-size ratio.

4. Non-magnetic Operation: They neither generate nor are influenced by magnetic fields, which is advantageous in environments where magnetic interference is a concern.

5. Low Power Consumption: Compared to other actuator types, piezoelectric actuators use less power, contributing to their energy efficiency.

6. Long Lifespan: Due to their solid-state construction and absence of moving parts, piezoelectric actuators have a reduced rate of wear and tear, leading to a longer operational life.

The benefits of piezoelectric actuators

Applications of Piezoelectric Actuators

1. Underwater Transducers: Piezoelectric actuators are used in underwater transducers to emit sonar signals and facilitate communication in aquatic environments.

2. Point Level Sensors: They are employed in point level sensors to detect the presence of liquid levels within tanks and containers, which is crucial for process control in various industries.

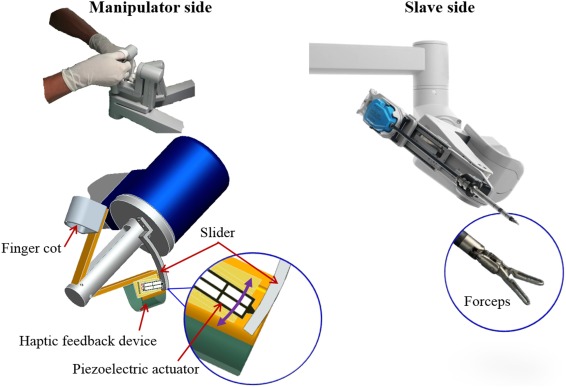

3. Medical Products: In the medical field, piezoelectric actuators find use in products like endoscope lenses, which are vital for diagnostic and therapeutic procedures.

4.Ultrasonic Cleaners: These actuators generate ultrasonic waves in cleaning applications, where objects are immersed in a solvent and cleaned by the vibrations produced by the piezoelectric transducer.

5. Ultrasonic Welding: Piezoelectric actuators are used to transmit ultrasonic waves that facilitate the joining of plastic materials through a process known as ultrasonic welding.

6. Piezoelectric Motors: They are utilized in motor designs that require precise control over expansion and contraction for accurate movements, especially in environments with strong magnetic fields or extreme temperatures.

7.Stack Actuators: By stacking multiple piezoelectric elements, the displacement achieved for a given voltage is multiplied, which is useful in applications demanding high precision and a fast response.

8.Stripe Actuators: These actuators, created by sandwiching two strips of piezoelectric material, can expand one strip while contracting the other, providing precise control over movement in various applications.

9.Industrial and Manufacturing: Piezoelectric transducers are used for precise and repeated pressure measurements in high-temperature applications such as steel production, injection molding, die casting, and chemical production, where reliability and accuracy are paramount.

Applications of Piezoelectric actuators

Frequently Asked Questions

1. What is a piezoelectric actuator?

Piezoelectric actuators are transducers that convert electrical energy into mechanical displacement or stress based on the piezoelectric effect, which is the ability of certain materials to generate an electric charge in response to applied mechanical stress. This effect is reversible, meaning that applying an electric field to a piezoelectric material can cause it to change shape.

2. Pros and Cons of Piezoelectric Actuators:

Pros: Compact size, extreme precision, and the ability to achieve nanometer-level control.

Cons:Very low speed, short travel range, potentially short lifetime, high cost, and sometimes the need for an external encoder for precise positioning.

3. Working Principle of Piezoelectricity:

The piezoelectric effect occurs when mechanical stress applied to a piezoelectric material causes the positive and negative charge centers within the material to shift, creating an external electrical field. Conversely, applying an external electrical field to the material can cause it to expand or contract.

4. Advantage of Piezo Actuators over Solenoid Actuators:

Piezoelectric actuators offer several advantages over solenoid actuators, including smaller size, lighter weight, extreme precision, durability, fast response times, and energy efficiency.

5. Advantage of Electric Actuators:

Electric actuators provide highly accurate control and positioning, which can help machines adapt to flexible processes. They also have low operating costs, making them energy efficient and potentially cost-saving in many applications.

6. Examples of Piezoelectric Actuators:

Piezoelectric actuators can be direct extensional types or flexure types, used in applications such as impact printers, autofocus systems in cameras, and ink-jet printers.

7. Voltage for Piezoelectric Actuators:

Piezoelectric actuators typically require high voltage (50V to 200V or more) to achieve significant force or displacement. The voltage can be generated using various methods, including amplifiers or transformers, and the choice depends on the specific application requirements.

JMBom Electronics, a company that collaborates with various manufacturers, specializes in providing a wide array of electronic components. Their product lineup includes semiconductors, antennas, capacitors, connectors, diodes, integrated circuits (ICs), and resistors. They have authored this article to share information. For an extensive range of product details, we invite you to visit their website.

Related Articles

Subscribe to JMBom Electronics !