What Are Ceramic Potentiometers?

Catalog

What Are Ceramic Potentiometers?Key Components of a Ceramic PotentiometerAdvantages Compared to Other Potentiometer TypesCommon Uses in ElectronicsStructure and Design of Ceramic PotentiometersWorking Mechanism of Ceramic PotentiometersTypes of Ceramic PotentiometersAdvantages and DisadvantagesMaintenance and TroubleshootingConclusionHave you ever wondered how your stereo system manages such precise volume control, or how your car’s dashboard dimmer adjusts the brightness so smoothly? The secret often lies in a small but powerful component called a ceramic potentiometer. In this article, we’ll take a closer look at how it’s built, how it works, and the different types you might come across — by the end, ceramic potentiometers might feel like your new go-to component.

What Are Ceramic Potentiometers?

A ceramic potentiometer is a type of variable resistor that uses a ceramic material as its base. Its main role is to manually adjust and control electrical resistance in a circuit. Thanks to the ceramic substrate, which offers excellent thermal stability and consistency, these potentiometers are especially suitable for use in high-temperature environments.

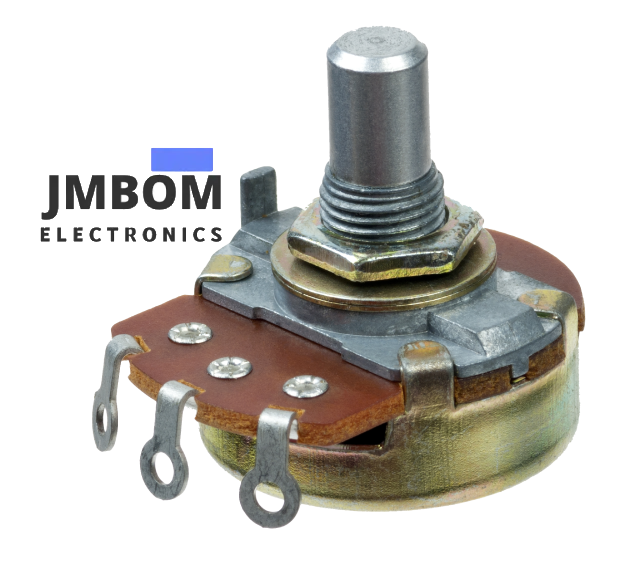

Key Components of a Ceramic Potentiometer

- Ceramic substrate: Provides the main structural support and offers excellent thermal stability.

- Resistive track: A conductive layer applied to the ceramic substrate that creates the resistance path.

- Wiper: A movable contact that slides along the resistive track to adjust resistance.

- Terminals: Connection points that allow the potentiometer to be wired into a circuit.

Advantages Compared to Other Potentiometer Types

- Works reliably in high-temperature environments

- Offers excellent long-term stability and durability

- Low noise during operation

- Resistant to humidity, chemicals, and other environmental factors

Common Uses in Electronics

- Industrial control equipment

- Audio devices and sound systems

- Automotive electronic systems

- High-temperature sensing applications

- Precision measurement instruments

Structure and Design of Ceramic Potentiometers

Wiper Mechanism

The wiper mechanism is a crucial part of any ceramic potentiometer, allowing for precise adjustments in resistance. This sliding contact moves smoothly across the resistive track to fine-tune the output. To ensure reliability and long service life, wipers are often made from durable materials like beryllium copper alloys or high-quality precious metals such as gold.

Resistive Track Composition

The resistive track is made using specialized ceramic materials. Manufacturers apply a cermet (ceramic-metal) resistive ink onto the ceramic base. The exact composition of this layer determines the potentiometer’s resistance range and performance characteristics.

Terminal Connections

Ceramic potentiometers typically feature three terminals: two fixed terminals at each end of the resistive track and one connected to the wiper. These terminals are commonly made from strong, conductive materials like brass or copper to ensure reliable electrical contact and durability.

Housing and Protective Features

The housing is designed to shield the internal components from external conditions. Many ceramic potentiometers use high-temperature-resistant materials for the casing, allowing them to perform well in tough environments. Some models also include protective elements such as gaskets or special coatings to guard against moisture, dust, and other contaminants.

Working Mechanism of Ceramic Potentiometers

Voltage Division Principle

Ceramic potentiometers work based on the simple principle of voltage division. The resistive ceramic track acts as a voltage divider, allowing precise control of the output voltage. As the wiper moves along this track, it splits the resistance into two sections, dividing the input voltage in proportion to their resistance values.

Adjustment Process and User Interaction

Users adjust a ceramic potentiometer by turning a shaft or sliding a knob. This mechanical movement changes the position of the wiper on the ceramic track. As the wiper moves, it alters the balance of resistance between the two sections of the track, which in turn changes the output voltage. This straightforward mechanism gives users smooth, intuitive control over different electronic settings.

Signal Output Variations

The output signal depends directly on the wiper position. When the wiper moves closer to one end of the track, the resistance on that side decreases and increases on the opposite side. This changing resistance ratio adjusts the output voltage, providing smooth and continuous variation of the signal. Thanks to the stable properties of the ceramic material, these changes are consistent and reliable, making ceramic potentiometers well-suited for precision applications.

Types of Ceramic Potentiometers

Ceramic potentiometers are available in several designs to suit different applications. Below are three of the most common types you’ll encounter.

Linear Potentiometers

Ceramic linear potentiometers provide a uniform change in resistance across their entire range of movement. As the wiper travels along the resistive track, the resistance changes in direct proportion to the distance moved. Because of this linear relationship, they are ideal for applications that require smooth, predictable control over a wide range, such as volume adjustment or position sensing in industrial machinery.

Logarithmic Potentiometers

Also known as audio taper potentiometers, logarithmic ceramic potentiometers have a non-linear resistance curve. As the wiper moves, the resistance changes logarithmically: the change is more gradual at first and becomes steeper toward the end of the rotation. This behavior closely matches how the human ear perceives changes in loudness, making these potentiometers especially suitable for audio volume controls and other sound-related applications.

Multi-turn Potentiometers

Multi-turn potentiometers are designed for applications that require very fine adjustment and high precision. Unlike standard single-turn potentiometers, which cover their full resistance range in one rotation, multi-turn versions require several turns of the shaft. This allows for much more accurate control, making them a great choice for calibration equipment, laboratory instruments, and other systems that demand highly precise settings.

Advantages and Disadvantages

Temperature Stability and Durability

Ceramic potentiometers perform extremely well in environments with wide temperature swings. Thanks to their ceramic construction, they offer excellent thermal stability and can maintain consistent performance across a broad temperature range. This reliability makes them a strong choice for automotive, aerospace, and industrial applications where stable operation is critical.

Precision and Accuracy in Measurements

One of the main benefits of ceramic potentiometers is their high precision. Their material properties support very fine resistance adjustments, allowing more accurate control of voltage or current. This level of accuracy is especially valuable in sensitive electronic circuits and measurement equipment.

Cost Considerations

Ceramic potentiometers generally cost more upfront than carbon or plastic types. However, they often provide better performance and a longer service life. Over time, this can reduce the need for replacements, making them more cost-effective in demanding or high-usage applications.

Size and Space Constraints

Compared to some other potentiometer types, ceramic versions can be larger and heavier. This can be a drawback in compact devices or applications where space, weight, or portability is a priority. While they may not be ideal for small handheld electronics, their robust construction makes them well-suited to industrial environments where size is less of a concern.

Maintenance and Troubleshooting

Common Issues with Ceramic Potentiometers

Although ceramic potentiometers are durable, they can still develop issues over time:

- Wear on the resistive track can cause unstable or noisy output

- Dust and debris can interfere with wiper movement and accuracy

- Moisture can lead to corrosion of internal components

These are important factors to keep in mind when selecting and using ceramic potentiometers.

Cleaning and Care Tips

Regular, gentle maintenance helps keep ceramic potentiometers performing well:

- Wipe the exterior with a soft, lint-free cloth

- For stubborn dirt, use a small amount of isopropyl alcohol, applied sparingly to avoid excess liquid entering the device

- Periodically rotate the shaft through its full range to help distribute any internal lubrication and prevent stiffness

When to Replace a Ceramic Potentiometer

Even though ceramic potentiometers typically have a long service life, there are times when replacement is the best option. Consider replacing the component if you notice:

- Erratic readings or sudden jumps in resistance

- Persistent noise or instability that cleaning doesn’t fix

- Physical damage to the housing or terminals

- The potentiometer can no longer meet the precision requirements of your application

Swapping in a new unit at this stage helps maintain reliable and accurate performance in your circuit.

Conclusion

Ceramic potentiometers play a key role in many electronic applications by offering precise resistance control along with excellent durability. Built on ceramic materials, they deliver strong thermal stability and can handle harsh operating conditions, making them a reliable choice in demanding environments. By understanding their structure, how they work, and the different types available, engineers and hobbyists can choose the most suitable option for their designs.

Ceramic potentiometers provide several benefits, such as high temperature resistance and long-term stability, but they also come with some trade-offs, including higher upfront cost and potential fragility compared with other types. With proper maintenance and basic troubleshooting, their service life can be extended and their performance kept at an optimal level. By weighing both the advantages and limitations, you can decide whether ceramic potentiometers are the right fit for your specific application.

Subscribe to JMBom Electronics !