Introduction to Force Sensors

Catalog

What’s the principle behind force sensors?What are Force Sensors?How Do Force Sensors Work?Things to Think About When Choosing a Force SensorHow Are Force Sensors Made?Construction and Design of Force SensorsHow Do Force Sensors Output Data?How Are MEMS (Micro-Electromechanical Systems) Made?Measuring Tiny Resistance ChangesWhat Does Force Sensor Accuracy Mean?Frequently Asked QuestionsRelated ArticlesWhat’s the principle behind force sensors?

In this section, we’ll dive into force sensors—how they work and what to keep in mind when selecting one.

What are Force Sensors?

Force sensors are devices that take a mechanical force—like weight, tension, compression, torque, strain, stress, or pressure—and turn it into an electrical signal. This signal tells us how strong the force is. It’s usually sent to indicators, controllers, or computer systems, where it can guide operators or be used in machinery and process controls.

Force Sensors

Even though force sensors and force transducers are technically different, people often use the terms interchangeably. These days, force sensors are in higher demand than ever, showing up in power equipment, engineering machinery, operating machines, and industrial automation systems. They come in all sizes, capable of measuring anything from a few hundred grams to hundreds of tons.

You’ll find force sensors in all sorts of applications—bathroom scales, musical instruments, medical devices, automotive seat sensors, and industrial process controls, to name a few. In this article, we’ll explore the different types of force sensors and how they work.

How Do Force Sensors Work?

Force sensors work by detecting an applied force and turning it into a value we can measure. There are different types of sensors, each using its own sensing method. For example, some use materials called force-sensing resistors, which change their resistance when a force is applied.

Force Sensor Operation

Force sensors usually have two main parts: electrodes and a sensing material. They measure the force applied to something by detecting changes in the resistance of force-sensing resistors. Most force sensors are built around these resistors.

Force-sensing resistors work on the idea of contact resistance. Basically, they use a conductive polymer sheet that changes its resistance when a force is applied. This sheet is made up of a mix of tiny conductive and non-conductive particles.

Force Sensor Principle of Operation

When you apply force to the film’s surface, the tiny particles inside make contact with the sensor electrodes. This changes the resistance of the film, and the amount of change tells us how much force was applied. In simple terms, the force or pressure changes the electrical resistance, and that change is measured.

Things to Think About When Choosing a Force Sensor

There are many types of force sensors, each designed for different uses. Chapter three will break down these types, but for now, let’s focus on the key factors to consider so you can make a smart choice.

Cost

Price is always a big deal. A more expensive sensor might make sense for some projects, but it could also hurt your budget or profits if it’s overkill for your needs.

Repeatability

Can the sensor reliably give you the same reading every time under the same conditions? That’s repeatability. While it’s related to accuracy, repeatability is more about consistency—getting the same result repeatedly, even if it’s not 100% accurate.

Accuracy and Precision

Accuracy and precision are super important but often misunderstood. Accuracy is about how close the measurement is to the true value, while precision is about how consistent the measurements are with each other. Knowing which one matters more for your project is key.

Environment

Think about where the sensor will be used. Temperature, humidity, and other conditions—like those in industrial, agricultural, medical, or automotive settings—can affect how well it works. For example, big temperature swings might mess with some sensors, while others are designed to handle those changes better.

Durability

How tough does your sensor need to be? Consider its lifespan, how well it can handle tough conditions, and how its performance holds up over time. A durable sensor might cost more upfront, but it’ll save you money and headaches in the long run by staying accurate and reliable.

Response Time

If you’re measuring fast-changing forces, you’ll need a sensor with a quick response time. For slower or steady forces, a slower response might be just fine.

Sensitivity

How sensitive does the sensor need to be? Some sensors, like open load sensors, are incredibly accurate and can be customized for different applications.

Form Factor

Finally, think about the size and shape of the sensor. Does it fit your product design? The technology you choose will depend a lot on your size and space constraints.

How Are Force Sensors Made?

In this chapter, we’ll take a look at how force sensors are built, designed, and manufactured.

Construction and Design of Force Sensors

Force sensors come in all kinds of shapes and sizes, depending on what they’re meant to do. But no matter the design, they’re typically made up of three main parts.

Construction and Design of Force Sensors

Force-Sensitive Components

This is the part that actually feels the force. It’s usually made from materials like aluminum alloy, alloy steel, or stainless steel, chosen for their strength and durability.

Circuit Section

The circuit is often made from enameled wire or a PCB board. This part connects everything together, making sure the sensor’s readings can be processed properly.

Conversion Element

The conversion element is what turns the force into something measurable. Most commonly, this is a strain gauge—basically, a small coil that detects changes caused by force. Another option is a piezoelectric sensor, which uses a crystal that reacts to pressure to produce an electrical signal. Both methods get the job done, just in slightly different ways.

Force sensors might look simple on the outside, but their design and materials are carefully chosen to handle specific tasks and environments.

How Do Force Sensors Output Data?

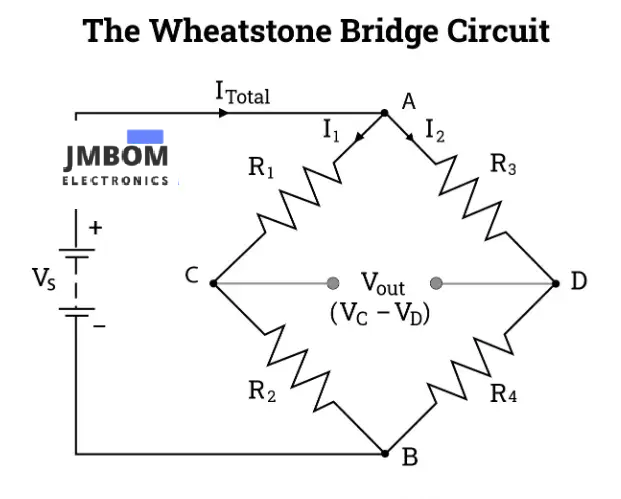

Force sensors can provide output in several formats, like analog voltage, analog current, analog frequency, switches or alarms, and even serial or parallel data. In simpler sensors, the measuring circuit usually has four gauges. For more advanced ones, the circuit can include up to 30 gauges. Adding more gauges makes the sensor better at picking up and tracking small measurement changes. These gauges and their circuits are often designed using the Wheatstone bridge equation.

Wheatstone Bridge Circuit

The Wheatstone bridge is a diamond-shaped circuit that uses variable resistance to measure unknown resistance values with high accuracy. It’s also great for calibrating devices like sensors. This setup can measure extremely low resistance values—down to milli-Ohms—by comparing the unknown resistance to known values.

Thanks to modern operational amplifiers, the Wheatstone bridge can now be paired with all kinds of transducers and sensors, making it useful in many applications. The circuit itself has two series-parallel resistor networks connected between a voltage supply and ground. When it’s balanced, there’s no voltage difference between the two branches.

how it’s laid out:

- Two input terminals and two output terminals.

- Four resistors arranged in a diamond shape.

This clever design is the backbone of many force sensors, helping them deliver accurate and reliable measurements.

Wheatstone Bridge Circuit

How Are MEMS (Micro-Electromechanical Systems) Made?

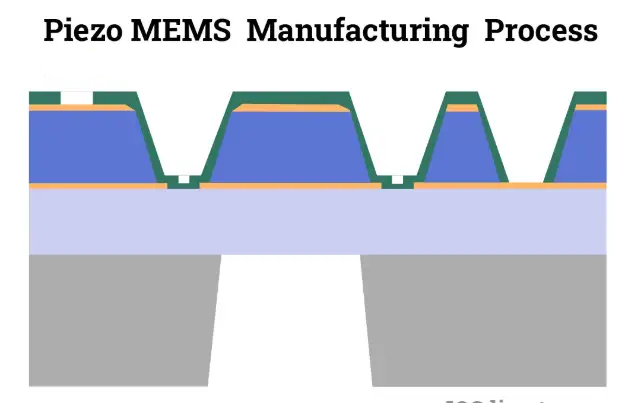

The process of making MEMS involves some pretty precise steps. Here’s a simplified breakdown:

Start with the Wafer

A layer of silicon nitride is added to both sides of an insulator wafer. On the front side, most of this nitride is etched away, leaving a thin silicon layer exposed and a nitride ring around the edge. This is done using a patterned etch mask and a reactive-ion etcher.

Protect the Silicon

The front side gets a coating of silicon oxide to shield the silicon underneath. On the back, the nitride is etched to create square windows, which will later become diaphragm-like structures.

Shape the Diaphragms

Silicon is etched away with potassium hydroxide (KOH) to create square silicon diaphragms suspended over open cavities. The nitride layer acts as a mask, and the oxide layer stops the etching in the right spots. These open cavities are then sealed with Pyrex wafers.

Etch the Pyrex Wafer

Channels are etched into the Pyrex wafer using hydrofluoric acid and a chromium-gold mask. The Pyrex has an engraved front and a smooth, clean back.

Bonding and Resistors

The SOI wafer and Pyrex wafer are bonded together. A metal layer is added to the front side through thermal evaporation, and resistors are etched onto this layer. The timing is important—metal patterning happens before the KOH etching and bonding but after the metal is deposited.

Waterproofing and Insulation

A thin Parylene polymer layer is applied to the front to waterproof and insulate the resistors. This ensures the device can handle different environments.

Final Steps

Pressure-sensing cells or arrays are cut from the bonded wafers using a die saw, then packaged for testing.

Measuring Tiny Resistance Changes

Since the resistance changes in these devices are super small, a Wheatstone bridge circuit is used to pick them up. This technique is common in piezoresistive and strain-gauge pressure sensors.

This entire process is precise and must follow a strict order to ensure the sensors work correctly.

Piezo MEMS anufacturing Process

What Does Force Sensor Accuracy Mean?

Accuracy is one of the key features of strain gauge load cells, especially when it comes to sensitivity. In simple terms, sensor accuracy refers to the smallest force the sensor can detect while still producing a reliable and consistent voltage change. The more accurate the sensor, the better it is at capturing tiny force variations consistently.

Special Strain Gauge Technology

FUTEK’s load cells use cutting-edge metal foil strain gauge technology. These strain gauges are specially designed to measure more strain around the active sensor element. This reduces errors caused by forces coming in at odd angles (off-axis loads) and makes the sensors less likely to be affected by installation mistakes. Plus, FUTEK’s proprietary foil strain gauges are fully encapsulated and include built-in compensation, which boosts reliability and ensures they stay accurate over time.

Linearity and Repeatability

For precise measurements, a sensor’s linearity is super important. FUTEK’s load cells are incredibly accurate, with nonlinearity and nonrepeatability levels as low as ±0.02% of the Rated Output (RO). This makes them ideal for demanding applications, like measuring rocket engine thrust in test stands.

Why Material Choice Matters

The core structure (or flexure) of FUTEK’s load cells is made from aerospace-grade 17-4 stainless steel or aluminum. These high-quality materials are both strong and flexible, so they can handle heavy loads, spring back to their original shape, and perform consistently. They’re also incredibly durable, offering:

- High strength and hardness.

- Low hysteresis (minimal lag in response).

- Low creep (minimal deformation over time).

- Excellent corrosion resistance, even across a wide range of temperatures.

This careful material selection ensures FUTEK’s sensors are tough, reliable, and precise in any conditions.

Frequently Asked Questions

What Does a Force Sensor Do?

A force sensor, also known as a load cell or force transducer, is a device that measures force by converting mechanical force into an electrical signal. When force is applied to the sensor, it changes the electrical signal, which can then be measured, converted, and standardized for further use.

What’s the Difference Between a Force Sensor and a Pressure Sensor?

While both sensors measure similar physical properties, the difference is simple: force is the total impact that one object has on another, while pressure is the force spread over a specific area. So, pressure is more about how force is distributed across a surface.

Types of Force Sensors

There are several types of force sensors, including:

Strain Gauge Load Cells: These are the most commonly used type of force sensor.

- Piezoelectric Force Sensors

- Capacitive Force Sensors

- Magnetic Force Sensors

- Optical Force Sensors

- Load Buttons and Compression Cells

- Force Sensing Resistors (FSRs)

What Are the Disadvantages of Force Sensors?

While force sensors are widely used, they do have some limitations. These can include issues with durability, relatively high power consumption, and lower robustness compared to other types of sensors.

How Accurate Are Force Sensors?

For example, the KM40 force sensor falls into accuracy class 0.2, with a load level accuracy of 0.16%. Another key factor for classification is the linearity deviation, which at 0.04% is very small and contributes to its high precision.

What Sensors Do Military Robots Use?

Military robots typically use proximity sensors to detect obstacles and location sensors to help navigate their environment.

Advantages of Force Sensors

Strain gauge-based force sensors offer several key advantages, including:

- They’re proven, cost-effective technology.

- High accuracy, with excellent linear and hysteresis behavior.

- Very good temperature compensation when combined with a Wheatstone bridge circuit.

What Does a Pressure Sensor Detect?

A pressure sensor detects and measures the pressure, which is the force applied over an area. Pressure sensors are particularly useful for enabling predictive maintenance, as they can gather real-time data on the condition of equipment.

What’s the Difference Between a Force Sensor and a Strain Sensor?

Strain sensors can be a good alternative to force sensors, especially for larger force ranges or rigid constructions. Unlike force sensors, strain sensors aren’t placed directly in the path of force. Instead, they’re mounted on the surface of the component being measured, and they detect deformation in the material caused by stress.

Related Articles

Proximity Sensors:Applications and Types

Pressure Sensors:A Complete Guide

Subscribe to JMBom Electronics !