Introduction to Position Sensors

Catalog

What is a Position Sensor?What is a Position Sensor Used for?Types of Position Sensors: The Working Principles of Position Sensors:The Advantages of Position Sensors Frequently Asked QuestionsRelated ArticlesWhat is a Position Sensor?

A position sensor is an apparatus designed to offer information about the spatial positioning or whereabouts of a mechanical element or vehicle. It serves as a crucial element in an array of systems that necessitate accurate management and surveillance of motion.

What is a Position Sensor?

What is a Position Sensor Used for?

1. Automotive Applications:

Fine-tuning the position of car seats and exterior mirrors.

Operating power-operated windows and roof panels.

Regulating the throttle and engine valve positions.

Keeping track of gear-shift lever positions.

Modulating the height of vehicle suspensions in systems with adjustable damping.

2. Industrial Automation:

Steering robotic arms and automated guided vehicles (AGVs).

Directing the motion of manufacturing machinery and production lines.

Aligning parts in machines designed for picking and placing.

Observing the positions of conveyor systems and other material transport setups.

3. Aerospace and Defense:

Governing the deployment of aircraft control surfaces like flaps and landing gear.

Following the trajectory of missiles and other munitions.

Coordinating the activation of safety mechanisms such as airbags and restraints.

4. Construction and Heavy Equipment:

Operating the boom and bucket of hydraulic excavating machinery.

Aligning elements in cranes and other hoisting devices.

Tracking the positioning of drilling bits and mining apparatus.

5. Medical Equipment:

Modulating the placement of hospital beds and operating tables.

Managing the navigation of robotic surgical instruments.

What is a Position Sensor Used for?

Types of Position Sensors:

1. Contact Sensors:

Contact sensors function through the interaction and compression when two objects touch, with common examples being limit switches and two-dimensional matrix position sensors.

2. Proximity Sensors:

Proximity sensors trigger a signal as an object nears a predetermined distance, eliminating the need for physical contact. They primarily consist of types such as electromagnetic, optoelectronic, differential transformer, eddy current, capacitive, reed switch, and Hall effect sensors.

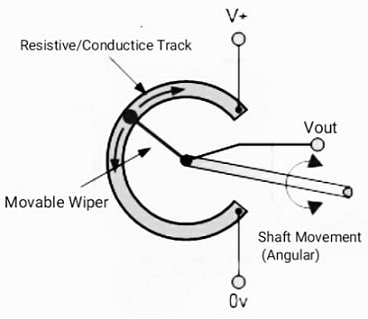

3. Resistive (Potentiometric) Position Sensors:

These sensors operate on the principle of resistance variation, using a stationary resistive element and a movable wiper that's attached to the object being tracked. As the object moves, the wiper slides across the resistive element, and the position is detected through a voltage divider circuit, indicating either linear or rotational movement.

4. Inductive Position Sensors:

Inductive position sensors detect changes in the properties of a magnetic field within the sensor's coil to gauge position, which can be either linear or rotational. They encompass devices like Linear Variable Differential Transformers (LVDTs) and Rotary Variable Differential Transformers (RVDTs).

5. Eddy Current Position Sensors:

Eddy current position sensors interact with conductive materials, generating currents within a fluctuating magnetic field. Comprising a coil and a linearization circuit, these sensors determine the object's position by the interaction between the induced currents and the coil's impedance.

6. Capacitive Position Sensors:

Capacitive position sensors identify the location of both conductive and non-conductive objects by monitoring shifts in capacitance. They pinpoint the object's position by changing either the capacitor's dielectric constant or the area where the plates of the capacitor overlap.

7. Magnetostrictive Position Sensors:

These contactless linear position sensors use the swift interchange of two magnetic fields to generate strain signals that travel along a waveguide.

8. Hall-Effect Based Magnetic Position Sensors:

These contactless position sensors locate objects by observing alterations in the orientation and strength of magnetic fields generated by electric currents, the Earth's magnetic field, and magnets.

Types of Position Sensors

The Working Principles of Position Sensors:

Position sensors, which come in various types, function based on distinct operational principles. Here are the working mechanisms of some widely used position sensors:

1.Potentiometric Position Sensors

These are composed of a resistive component and a sliding contact, known as a wiper. As the object under measurement shifts, the wiper moves across the resistive component, thereby altering the resistance between the wiper and the component's terminals. By monitoring this resistance variation alongside a reference voltage, the object's position is ascertained through the voltage division rule.

2.Capacitive Position Sensors

They are made up of a pair of conductive plates, and the capacitance between these plates depends on the distance, plate area, and the dielectric material's permittivity that separates them. Any change in the object's position modifies these factors, leading to a capacitance fluctuation. Tracking this change and translating it into an electrical signal yields the positional data of the object.

3.Optical Position Sensors

Optical Encoders: Comprising a light emitter, a coded disc, and a photodetector, the disc is patterned with alternating transparent and blocking segments. As the disc rotates or translates with the moving object, the light passing through these segments is detected by the photodetector, which then transforms light intensity variations into electrical pulse signals. By analyzing these pulses, the object's exact position and movement are deduced.

Laser Triangulation: A laser source directs a laser beam towards the surface of the object. The reflected light is captured by a photodetector. Using the angles of incidence and reflection, along with the location of the reflection point on the object's surface, the object's position is derived from the principles of trigonometry.

4.Ultrasonic Position Sensors

These devices transmit ultrasonic waves that bounce off the target object and return to the sensor. By measuring the time lag between the wave emission and the echo reception, and knowing the velocity of sound, the sensor calculates the distance to the object, thereby pinpointing its location.

The Working Principles of Position Sensors

The Advantages of Position Sensors

1. High Accuracy: Position sensors deliver precise measurements, essential for applications demanding exact positioning and control.

2. Sturdiness: Engineered for operation in tough conditions, position sensors are built to last and provide dependable performance over time.

3. Diversity: A range of types is available, allowing position sensors to be deployed across many sectors, including aerospace and medical technology.

4. Instantaneous Response: Position sensors provide rapid feedback, which is critical for dynamic systems and automated processes, facilitating immediate adjustments and management.

5. Trustworthiness: Proximity sensors are highly reliable and enduring, attributed to their lack of mechanical components and non-contact operation.

6.Flexibility: Position sensors preserve their accuracy across a variety of conditions, such as extreme temperatures or vibrations, rendering them fit for a broad array of scenarios.

The Advantages of Position Sensors

Frequently Asked Questions

1. What are the three types of Position Sensors?

Position sensors can be categorized based on the type of measurement they provide: linear, rotary, or angular. They can also be distinguished by whether they measure static positions or dynamic movements (including speed and/or acceleration). Linear sensors often have a specific range within which they operate, while rotary sensors typically measure in revolutions or degrees.

2. What are the advantages and disadvantages of Position Sensor?

An example of a simple positional sensing circuit is the resistive potentiometer position sensor. These sensors have several benefits, such as being cost-effective, low-tech, and user-friendly. However, they also have drawbacks, including wear from moving parts, low precision, poor repeatability, and a limited frequency response.

3. How many types of Position Sensors are there?

There are various types of position sensors capable of measuring positions in three dimensions. Advances in position detection technology include sensors that are potentiometric, inductive, eddy current, capacitive, magnetostrictive, Hall effect, fiber optic, optical, and ultrasonic.

4. What is an example of a Position Sensor?

Position sensors utilize a motion detection mechanism to ascertain the presence of humans or other objects within a particular area. Examples include rotary encoders and Hall effect sensors.

5. What are the applications of Position Sensor?

Position sensors are employed in a multitude of applications across various industries, such as automotive, motorsports, medical, agriculture, robotics, industrial processing, mobile vehicles, testing and laboratory applications, food and beverage, packaging, machine tools, and wrapping, among others.

6. What is the purpose of the Position Sensor?

A position sensor is a device that gathers information about the exact location and movement of an object. This information can be acquired either through direct contact with the object or indirectly using magnetic sensors. It is also capable of measuring the thickness of a part, the level of a liquid, or the angle of rotation of an axle.

Related Articles

What are Optical Sensors & How they work

Analog vs. Digital Sensors: Key Differences Explained

Proximity Sensors:Applications and Types

Subscribe to JMBom Electronics !