What is a Conductivity Sensor?

Catalog

What is a Conductivity Sensor? The key Technologies of Conductivity Sensors:Working Principle of Conductivity SensorThe Advantages of Conductivity Sensors Frequently Asked Questions Related ArticlesWhat is a Conductivity Sensor?

A device that gauges the electrical conductivity of a liquid is known as a Conductivity Sensor. Electrical conductivity refers to how well a substance can transmit electric current. In terms of Conductivity Sensors, this property is utilized to ascertain the ion concentration within a liquid, which is inherently linked to the liquid's electrical conductivity.

The conductivity level of a liquid is affected by the dissolved ions present, including positively charged ions (cations) and negatively charged ions (anions). Sodium (Na+), chloride (Cl-), and other ions are typical contributors to conductivity. The greater the ion concentration in a liquid, the more efficiently it conducts electricity.

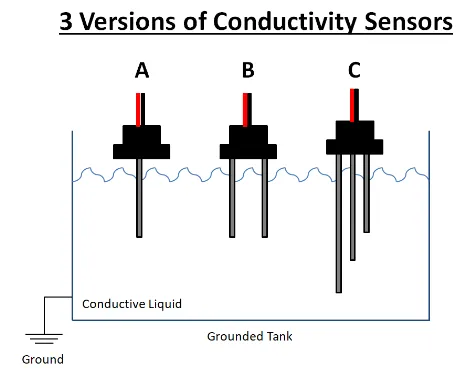

Conductivity Sensors generally incorporate two or more electrodes that are submerged in the liquid. An electrical voltage is imposed across these electrodes, and the consequent electric current is measured. The liquid's conductivity is subsequently determined by calculating the ratio of the measured current to the applied voltage.

What are Conductivity Sensors?

The key Technologies of Conductivity Sensors:

1. Electrode Setup: Conductivity Sensors operate with two principal electrode setups, either the two-electrode or the four-electrode system. The two-electrode setup is straightforward and ideal for fundamental applications, comprising one electrode to apply voltage and another to measure the current. The four-electrode setup includes two extra electrodes that reduce the impact of electrode polarization and contact resistance, ensuring enhanced precision and stability, particularly for more demanding applications.

2. Alternating Current (AC) and Direct Current (DC) Detection: AC Conductivity Sensors utilize alternating current to reduce electrode polarization effects, leading to more reliable and precise measurements, especially in solutions with low conductivity. DC Conductivity Sensors are more straightforward and frequently employed for basic applications, using direct current to assess conductivity.

3. Cell Constant and Electrode Form: The cell constant, a critical factor for the sensitivity and accuracy of conductivity measurements, is the ratio of electrode spacing to the sensor's cross-sectional area. Varying electrode forms, such as cylindrical or planar configurations, can influence how the sensor performs in different solution types.

4.Thermal Compensation: Numerous Conductivity Sensors are equipped with temperature sensors to adjust for the temperature-related changes in conductivity. This compensation guarantees precise measurements across a variety of temperatures.

5. Electrode Substances: Stainless steel is prevalent in industrial settings because of its resistance to corrosion; platinum is favored in high-precision applications and laboratory-grade sensors; graphite is selected for applications involving harsh or corrosive solutions.

6. Advanced Sensor Technology: Certain contemporary Conductivity Sensors feature digital interfaces that facilitate their integration into digital control systems and offer extra functionalities like calibration alerts and diagnostic capabilities.

the key technologies of Conductivity Sensors

Working Principle of Conductivity Sensor

The operational mechanism of a Conductivity Sensor is grounded in the electrical conductivity of a liquid, which quantifies its capacity to transmit electric current. Here's a straightforward elucidation of the operational principle:

1. Electrodes: A standard Conductivity Sensor is equipped with two or more electrodes crafted from conductive materials. These electrodes are typically positioned at a predetermined distance apart.

2. Voltage Application: A voltage, or electrical potential, is imposed across the electrodes. This establishes an electric field within the liquid that spans the gap between the electrodes.

3. Ion Migration: Within the liquid, an assortment of ions (charged particles) may exist, enhancing the solution's conductivity. These ions can be either positively charged (cations) or negatively charged (anions). Upon the application of the voltage, these ions are drawn towards the electrode with the opposite charge.

4. Electric Current: As ions traverse the liquid towards the electrodes, they generate an electric current. The more concentrated the ions in the solution, the stronger the current, and thus, the greater the conductivity.

5. Current Measurement: The sensor quantifies the current passing between the electrodes. The solution's conductivity is then determined using Ohm's Law (I = V/R), where I represents the current, V the voltage, and R the electrical resistance. Conductivity (σ) is commonly expressed in units of Siemens per meter (S/m) or microsiemens per centimeter (μS/cm).

6. Temperature Adjustment: Given that conductivity is temperature-sensitive, many Conductivity Sensors incorporate temperature compensation features. This ensures that temperature fluctuations do not significantly impact the precision of the conductivity reading.

Working principle of Conductivity Sensor

The Advantages of Conductivity Sensors

1. High Accuracy: Conductivity Sensors precisely capture variations in the conductivity of liquids under test. Contemporary Conductivity Sensors are typically highly precise, able to measure conductivity with an error margin of ±1% or less.

2. Reliable Durability: These sensors are crafted with specialized materials and techniques that ensure consistent performance over time, guaranteeing dependable measurement outcomes.

3. Swift Response: Conductivity Sensors boast a quick response time, delivering precise measurements rapidly, which is invaluable for applications that necessitate immediate monitoring.

4. Versatile Applications: Conductivity Sensors are versatile, capable of measuring a broad spectrum of liquids such as potable water, sewage, ocean water, and industrial fluids. This versatility makes them applicable across a multitude of sectors.

5. Resistant to High Temperatures and Pressures: Certain Conductivity Sensors possess traits that enable them to withstand extreme temperatures and pressures, enabling them to function in severe environments and cater to the demands of specific industries.

6. User-Friendly: The operation of Conductivity Sensors is straightforward, eliminating the need for specialized skills or equipment, thus simplifying the user experience and lowering the entry barrier.

7. Cost-Effective Maintenance: These sensors are designed for easy maintenance, facilitating routine upkeep and calibration for users. This helps preserve the sensor's measurement precision and prolongs its lifespan, reducing overall maintenance expenses.

8. Advanced Management Capabilities: Modern Conductivity Sensors can interface with other smart devices for remote monitoring and management, thereby elevating the sophistication of intelligent production management systems.

The advantages of Conductivity Sensors

Frequently Asked Questions

1. What is a Conductivity Sensor?

A Conductivity Sensor is an instrument engineered to gauge the electrical conductivity of a liquid. This property indicates how well a substance can transmit electric current, and for Conductivity Sensors, it's employed to evaluate the ion concentration within a liquid.

2. What are conductometric sensors?

Conductometric biosensors are compact, dual-electrode apparatuses where an alternating current (AC) voltage across the electrodes induces a flow of current. Muhammad-Tahir and Alocilja detailed a conductometric biosensor tailored for detecting E. coli O157:H7 and Salmonella species.

3. Why do we measure conductivity?

Assessing conductivity in freshwater bodies like lakes, rivers, and ponds offers a swift and practical method to identify pollution incidents or other system alterations. It is particularly valuable as a strategy for ongoing monitoring.

4. How do you test a Conductivity Sensor?

Conductivity can be assessed using either the 2-AC bipolar technique or the electromagnetic induction technique. The bipolar technique quantifies the current traversing the liquid between a set of electrodes. The electromagnetic induction technique, on the other hand, measures the induced current generated by a pair of coils submerged in the liquid.

5. What is the working principle of a sensor?

A sensor translates the physical quantity to be measured into an electrical signal and processes it so that these electrical signals can be readily transmitted and further analyzed. The sensor can indicate whether an object is present or absent (binary output) or what specific measurement has been achieved (analog or digital reading).

6. What is the purpose of a Conductivity Sensor?

Conductivity Sensors are utilized to quantify the conductivity of a liquid, which is a gauge of its electrical conduction capability. The conductivity level of a liquid is inherently linked to the ion concentration it contains.

Related Articles

Subscribe to JMBom Electronics !