What are DIP Switches?

Catalog

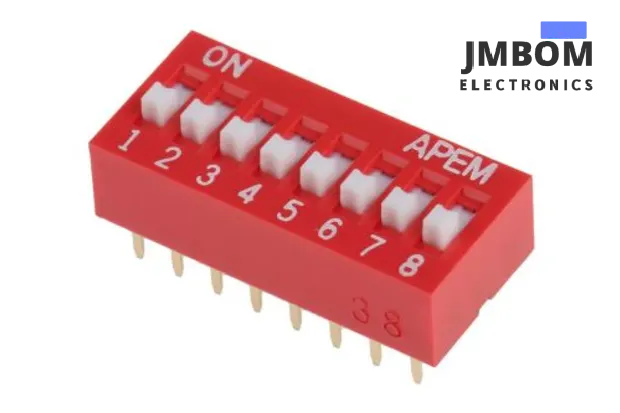

What Do DIP Switches Do?Primary Features of DIP SwitchesSpecifications of DIP SwitchesWorking Principle of DIP SwitchesApplications of DIP SwitchesWhat should be noticed when using DIP switches?Advantages and Disadvantages of DIP SwitchesVarieties of DIP SwitchesRotary DIP switchesFrequently Asked QuestionsWrapping UpRelated ArticlesA DIP switch, referred to dual in-line package switch, consists of a row of miniature switches housed within a single casing. This type of switch is frequently used in electronic and computing equipment to adjust hardware configurations. Here is an article from JMBom to show you more information about DIP switches.

DIP switch

What Do DIP Switches Do?

In essence, the role of DIP switches is to enable users to control the flow of electricity on a printed circuit board (PCB), expansion card, or other electronic or computer peripheral. By doing so, they allow users to change the operating mode or configuration of a device.

Primary Features of DIP Switches

DIP switches are commonly arranged as a series of small toggle switches, resembling a line of miniaturized standard light switches, placed in sequence on a block made of heat-resistant thermoplastic material.

A typical DIP switch could comprise 1, 2, 4, 7, 8, 10, 16, or an even greater number of toggle, rocker, slide, or rotary switches integrated into a single compact block. Despite their simplicity, the advantage of DIP switches lies in the ability to independently set each switch to an on (1) or off (0) position, enabling a vast array of possible settings and combinations.

Specifications of DIP Switches

Terminal type options available for DIP switches are diverse, including quick connect or blade types, surface mount technology configurations, straight PC pins, right angle PC pins, and side PC pins. Standard features often associated with DIP switches encompass imprinted labels for easy identification, tape and reel packaging for convenience in manufacturing and so on.

Working Principle of DIP Switches

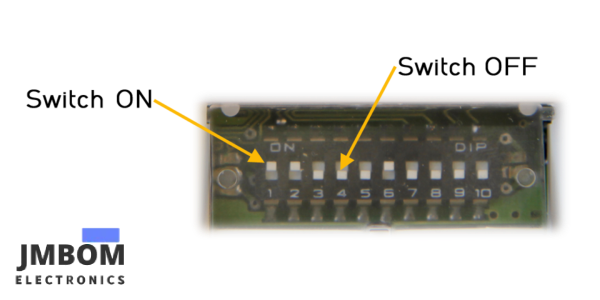

Each individual toggle within a single DIP switch array is electrically insulated from the others. When a toggle is switched between its on and off positions, the underlying flexible leaf spring beneath the switch moves in response to the slider or rocker, slightly bending up or down to either close or break the static contact beneath it, thereby engaging with a multitude of potential device functionalities or outputs.

By configuring the switches in a particular sequence, one can select an address, activate specific features, or adjust various parameters. This is the reason why DIP switches are frequently used for configuring hardware, establishing memory addresses, and choosing options on a circuit board.

DIP switch

Applications of DIP Switches

Typical uses for DIP switches in contemporary devices and circuits encompass:

1. Setting up various preferences on computer hardware and related peripherals, such as motherboards, graphics cards, hard drives, modems, and additional expansion cards or auxiliary devices.

2. DIP switches are frequently incorporated into the control systems of garage door openers.

3. They are often utilized in universal remote controls for multiple devices to minimize the risk of electrical interference that could cause unwanted operation of other devices.

4. DIP switches allow for the configuration of unique radio frequencies for each individual transmitter-receiver pair.

What should be noticed when using DIP switches?

DIP switches are classified for specific functions and applications based on their safe operating current, voltage, and power ratings. Users must adhere to the manufacturer's specified parameters for a given DIP switch to prevent issues such as switches welding themselves shut or electrical arcing during operation, which could lead to performance degradation or damage to the device.

Advantages and Disadvantages of DIP Switches

Advantages:

Versatility and Speed: DIP switches serve as an alternative to jumper blocks, offering the advantage of quick position changes without the risk of losing any components.

Simplicity and Cost-Effectiveness: They are straightforward to use, offer flexibility in configuration, and are an economical option.

Real-Time Configuration Visibility: DIP switches allow for the inspection of settings without the need to power on the system, which is particularly convenient in circuit design.

Interference Prevention: They are utilized in devices to establish unique radio frequencies or addresses for each transmitter/receiver pair, preventing unintended control issues when multiple units are installed.

Disadvantages:

Declining Popularity: With the advent of software-based customization, DIP switches have seen a decrease in demand as software configurations offer easier and more flexible options.

Limited to Industrial Use: Despite their continued use in industrial equipment for various functions, their application in other areas has diminished due to advancements in technology that provide more sophisticated configuration methods.

Varieties of DIP Switches

A wide array of DIP switches can be procured from numerous suppliers and manufacturers on the market, both in the UK and in other regions. The most frequently encountered types with most sellers are rotary, slide or rocker DIP switches.

All kinds of DIP switches are extensively utilized across various industries and applications nowadays, including:

- PC expansion cards

- Arcade machines

- Automatic garage doors

- Measurement and test devices

- Industrial sectors and machinery controls

- Production and editing equipment

All the different DIP switch configurations essentially perform the same function, but the form factor and the exact method of toggling between on/off positions will differ for rotary, rocker and slider styles.

In this section, we’ll provide a brief overview of some of these alternative DIP switch types.

Rotary DIP switches

A rotary DIP switch is one that the user turns through a circular range of motion - rather than toggles back and forth - either manually, or with a tool such as a screwdriver if that’s how the switch was designed to be actuated. Like rocker and slider varieties, rotary coded DIP switches are also meant to be mounted directly to a PCB to control the output behaviors of an electronic device.

They can be designed to rotate continuously through 360 degrees, or to stop at preset positions during rotation. The amount of rotation the DIP switch shaft passes through determines the binary or hexadecimal circuit code generated, and consequently the output signal sent to the device it’s connected to.

While most rotary DIP switches can be used in similar applications as other types, they’re often seen as particularly useful options in scenarios where space on the PCB is especially limited, or where ease of adjustment for the user is considered crucial.

They’re available in waterproof, weather resistant and dustproof models from some sellers, and are widely used in precision measurement gauges, sound mixing and editing, test equipment, aerospace and military voice/data communications, and radio transmitters and receivers.

Slide/rocker/piano DIP switches

Slide DIP switches, rocker DIP switches and piano DIP switches are essentially variations of the second main type of DIP switch, namely the more traditional toggle switch. For all of these switch types, you can purchase multiple variants including:

Normally open (NO), meaning that their default position is to be disconnected from a circuit, and actuating the switch will complete it again

Normally closed (NC), meaning that actuating the switch breaks contact with the circuit, rather than closing it

A three-stage switch, which will have three selectable positions (often On/Off/On), where the middle position will be default and pushing or sliding the switch to either side will actuate it

Additionally, like the vast majority of all toggle switch types, DIP switches can also be found in various pole and throw configurations, including:

Single pole single throw (SPST) - this is the simplest type of switch you’ll encounter in most device types, in which a single toggle either connects or disconnects a single terminal to/from another one

Single pole double throw (SPDT) - an SPDT switch forces the operator to choose between connecting to either one of two terminals; as such, the switch will always be connected to one or the other, and the two terminals will never be connected together (although there may be a third position for ‘neither’ available, particularly when using slide switches)

Double pole double throw (DPDT) - essentially functions exactly like two separate SPDT switches, but where both sets of dual terminals are connected to a single actuator; the DPDT switch can control two separate circuits, but these are always switched together when the toggle is moved.

The number of individual switches on a single DIP switch module can range from one or two to 16 or more, and the number of positions advertised for a particular module will correspond to the number of individual switches it contains. Some popular configurations or naming conventions you might come across in daily shopping include:

- 2 position dip switch

- 3 position dip switch

- 4 way dip switch

- 8-pin dip switch

- 8 way dip switch

- 10 position dip switch

- 10 dip switch

Frequently Asked Questions

What is a DIP switch used for?

They are typically installed on a PCB or breadboard, DIP switches enable users to swiftly pre-set or switch an electronic device through a range of configurations or operational modes.

What is the difference between a DIP switch and a slide switch?

DIP switches represent a specialized type of slide switch, often used on printed circuit boards or motherboards for configuring fundamental settings.

What are the different types of DIP switches?

A variety of DIP switches exist in the market. The most common types include slide, piano, IC, and SMD types, all of which operate using a toggling or sliding mechanism.

How to select DIP Switches?

When selecting DIP switches, consider the following crucial electrical specifications: the maximum current rating, the highest AC voltage rating, the peak DC voltage rating, and the maximum power rating.

Wrapping Up

Although the usage of DIP switches has experienced a modest decline in certain modern applications due to the growing affordability of software control panels and programmable onboard chips, which have somewhat reduced their popularity, DIP switches continue to be considered a highly appealing choice in a broad spectrum of industrial environments and within the realms of circuit and device testing and design processes.

Related Articles

Subscribe to JMBom Electronics !