A Complete Guide to Reed Switches

Catalog

Definition of Reed SwitchesHow Do Reed Switches Work The Advantages of Reed Switches: The Applications of Reed Switches Frequently Asked QuestionsRelated ArticlesDefinition of Reed Switches

Reed switches are a category of electrical switches that work on the detection of magnetic fields.It is designed to open or close an electrical circuit in response to the presence or absence of a magnetic field. Here's a more detailed explanation:

1. Construction: A Reed switch typically consists of two or three magnetically sensitive contacts, known as reeds, which are made from ferromagnetic materials like nickel-iron alloys. These reeds are sealed within a small, usually glass, envelope to protect them from the environment.

2. Operation: The reeds are positioned so that they do not touch each other when there is no magnetic field present. When a magnetic field is applied, the reeds are drawn together by the magnetic force, making contact and completing the electrical circuit. The strength of the magnetic field determines whether the reeds will touch and close the switch.

3. Types:

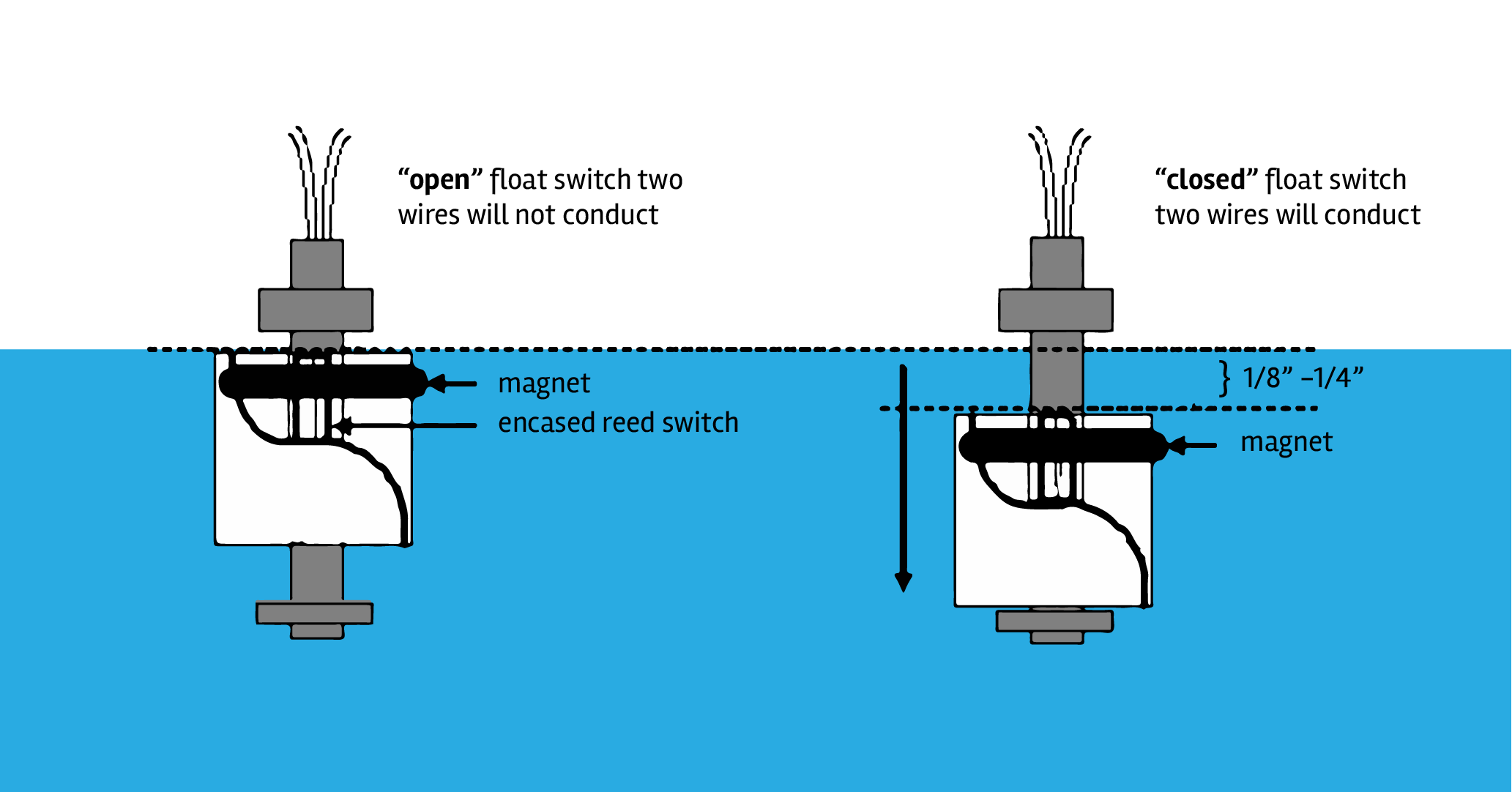

Normally Open (NO): In this configuration, the reeds are not in contact when there is no magnetic field. They only close the circuit when a magnetic field is applied.

Normally Closed (NC): Here, the reeds are in contact and the circuit is closed when there is no magnetic field.A magnetic field's presence leads to the reeds separating and consequently the circuit being broken.

Changeover (or Form C): This type has three reeds and can be used to switch between two different circuits when a magnetic field is applied. It can be thought of as a combination of NO and NC functions in one switch.

Reed switches offer a non-contact switching solution that is often preferred in situations where a high number of operations or harsh environmental conditions could compromise the reliability of mechanical switches.

Reed Switches

How Do Reed Switches Work

1.Reed switches consist of two separate wire contacts, referred to as reeds, which are enclosed within a sealed glass container or envelope. This container is often filled with an inert gas, such as nitrogen, to prevent the accumulation of particles that could degrade performance over time. For added durability in certain environments, the glass envelope might be surrounded by a plastic casing.

2.The reeds within the switch are made from ferromagnetic materials, which are iron-based metals that are highly responsive to magnetic fields. Typically, these are alloys composed of nickel and iron, with a common composition being 52% nickel. To enhance their longevity, these reeds are often covered with a layer of a more robust metal. In some varieties of reed switches, only one of the contacts is ferromagnetic, while the other remains stationary. Both reeds are shaped like blades, with a flattened and expanded contact area, which increases their reliability compared to contacts with a single point of contact.

3.The contacts are coated with an ultra-thin layer of metals such as iridium, rhodium, or ruthenium, which is applied over a base layer made from tungsten, copper, or gold. In some cases, silver, known for its low electrical resistance, is used, and certain reed switches even incorporate mercury. This additional layer ensures optimal electrical conductivity. Since these contacts are wetted with metal, the switches must be mounted in specific orientations to prevent the liquid metal from flowing and creating an unintended connection between the contacts when not activated.

4.The presence of a magnetic field near the exterior of the reed switch causes the internal contacts to either come together or separate. This movement either finalizes or disrupts the electrical circuit, contingent on the direction in which it occurs.In the most common type, the normally open reed switch, the two contact blades are slightly separated by an air gap, rendering the circuit incomplete until a magnetic force is applied.Conversely, in a normally closed switch, the contacts are in contact when there is no magnetic force present. The introduction of a magnetic field pushes these contacts apart, thereby interrupting the circuit. In both scenarios, the reeds' spring tension returns them to their resting position when the magnetic force is removed.

5.Finally, change-over switches, which have three reeds, perform a break-before-make operation. This means that one contact breaks its connection with another before establishing a connection with the third contact.

How Do Reed Switches Work

The Advantages of Reed Switches:

1. Extended Service Life: Characterized by their robustness, reed switches can endure millions of operational cycles without succumbing to failure, rendering them perfect for applications that demand utmost dependability.

2. Enhanced Dependability: The hermetic sealing of reed switches shields the contacts from external elements such as dust, humidity, and mechanical shocks, which could otherwise impair the functionality of other switch types.

3. Minimal Energy Usage: The operation of reed switches demands a minuscule amount of power, as they solely need to counteract the magnetic forces that separate the contacts. This attribute renders them highly energy-efficient.

4.Swift Reaction Speed: Reed switches are capable of reacting to fluctuations in magnetic fields with near-instantaneous speed, making them well-suited for applications that necessitate quick switching actions.

5.Simplicity and Durability: The fundamental construction of a reed switch is uncomplicated, featuring minimal moving components, which in turn minimizes the probability of mechanical malfunctions.

6.Minimal Electrical Resistance: Upon the closure of a reed switch's contacts, they exhibit a very low level of resistance, which aids in reducing power dissipation within the circuit.

The Advantages of Reed Switches

The Applications of Reed Switches

1. Security Applications: These switches are frequently employed in security systems, including alarms and sensors for doors and windows, to detect any unauthorized access. The disruption of the magnetic field when a door or window is opened can set off an alarm.

2. Telecommunication Sector: Reed switches play a role in pulse dialing within the telecommunications industry, facilitating smooth connections and efficient communication.

3. Automotive Sector: They are integrated into numerous automotive components, such as lighting controls, fuel gauges, and tire pressure monitoring systems, enhancing vehicle efficiency and safety.

4. Home Appliances and Electronics: Reed switches are instrumental in managing water flow and door closures in appliances like washing machines and refrigerators. They also enable accurate detection of fluid levels, preventing overflows and potential damage.

5.Medical Devices: Ultra Miniature Magnetic reed sensors are crucial for precise positioning and control in devices such as pumps, hearing aids, and ventilators. They also contribute to the accurate detection of fluid levels in diagnostic equipment, ensuring reliable measurements and outcomes.

6.Green Energy: Reed switches are implemented in wind turbines and solar energy systems to oversee and regulate operations, ensuring peak performance and efficiency. They assist in gauging wind velocity and adjusting solar panel angles to optimize energy production and minimize expenses.

The Applications of Reed Switches

Frequently Asked Questions

1. Purpose of Reed Switches

Reed switches, activated by magnets, are widely utilized as proximity sensors in mechanical systems. They are found in security systems like burglar alarms for door and window sensors and as tamper-proofing mechanisms. Additionally, reed switches have been employed in laptops to trigger sleep or hibernation mode when the lid is closed.

2. Uses of Reeds

Dried reed stems have been employed for thousands of years in various applications such as thatching and construction, basket weaving, arrow and pen making, and in the creation of musical instruments (reed instruments). They are also harvested for their cellulose content.

3. Difference Between Auto Switch and Reed Switch

The distinction between reed and solid-state auto-switches lies in their detection methods. Reed auto-switches use mechanical contact points through the reed switch for output, while solid-state auto-switches rely on magnetic detection elements and electronic circuits for output.

4.Role of Reeds in Weaving

A reed is a component of a weaving loom, resembling a comb or a frame with numerous vertical slits. It functions to separate and space the warp threads, guide the shuttle's movement across the loom, and push the weft threads into position. In most floor looms, the reed is securely held by the beater.

5. Power Requirements for Reed Switches

When using permanent magnets, reed switches do not consume any electrical power, eliminating the need for power supplies, electrical circuits, and timing circuits. The state of the reed switch is maintained without power (unlike Hall sensors) and depends solely on the movement of magnets within its influence.

6.Durability of Reed Switches

The expected lifespan of a reed switch is approximately 10^6 switching cycles at maximum power. With a low resistive load, the lifespan can extend to 5x10^8 operations. Mechanically, the lifespan can reach at least 10^9 operations without any load.

Related Articles

Subscribe to JMBom Electronics !