Types of Thermistors – How They Work and Their Applications

A thermistor is a temperature-sensitive device made from sintered semiconductor material, which shows a significant change in resistance with even small temperature changes. It can operate across a broad temperature range, and the temperature can be determined by measuring its resistance. The term "thermistor" is a combination of "thermal" and "resistor." The two main types of thermistors used in temperature-sensing applications are Positive Temperature Coefficient (PTC) and Negative Temperature Coefficient (NTC).

Types of Thermistors

Thermistors are simple to use, affordable, durable, and provide reliable responses to temperature changes. They are commonly found in digital thermometers and household devices like ovens and refrigerators, among others. The key qualities of thermistors—such as stability, sensitivity, and time constant—make them reliable, portable, cost-effective, and highly sensitive, making them ideal for measuring temperature at a single point.

There are two main types of thermistors

- Positive Temperature Coefficient (PTC) Thermistor

- Negative Temperature Coefficient (NTC) Thermistor

PTC Thermistor

PTC thermistors are resistors with a positive temperature coefficient, meaning their resistance increases as the temperature rises. These thermistors can be categorized into two groups based on their structure and manufacturing method. The first group includes silistors, which use silicon as the semiconductor material. Thanks to their linear characteristics, silistors can be used as PTC temperature sensors.

PTC thermistors

The second group of PTC thermistors includes switching-type thermistors, which are commonly used in heaters. Another type in this group is polymer thermistors, made from plastic. These are often used as resettable fuses due to their ability to return to their original state after the temperature drops.

Types of PTC Thermistors

PTC thermistors are classified according to the temperature levels they measure. These classifications depend on the following factors:

- Elements: PTC thermistors come in different shapes, such as disk, plate, and cylinder types.

- Lead and Dip Type: These thermistors can be painted or non-painted. They typically feature high-temperature coatings for mechanical protection, environmental stability, and electrical insulation.

- Case Type: The casing of these thermistors can be made from plastic or ceramic, chosen based on the specific needs of the application.

- Assembly Type: These thermistors are unit products due to their particular construction and shapes.

Typical Characteristics of PTC Thermistors

The characteristics of PTC thermistors reveal how various parameters like temperature, resistance, current, voltage, and time are interrelated. Here's an example:

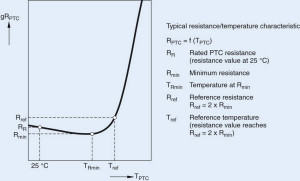

- Temperature vs. Resistance:

In the figure below, we can see how the resistance of a PTC thermistor changes with temperature. Initially, the resistance increases gradually with temperature. However, at higher temperatures, particularly near the Curie point, the resistance experiences a sharp increase. This shows a typical PTC (Positive Temperature Coefficient) behavior, where resistance rises significantly with only a slight temperature change once the thermistor passes the Curie point.

Temperature dependence of resistance

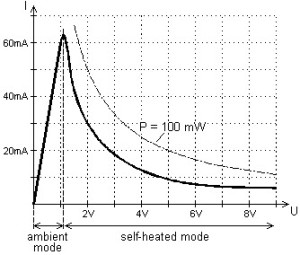

2.Current/Voltage Characteristics

This characteristic illustrates the relationship between voltage and current when the thermistor is in a thermal equilibrium state, as shown in the figure. As the voltage increases from zero, both the current and the temperature rise. This continues until the thermistor reaches a switching point. Beyond this point, further increases in voltage cause a decrease in current, even though the power remains constant in that region. This behavior is typical of PTC thermistors, where the current decreases as the temperature rises beyond the switching point, despite the voltage increase.

Current\Voltage characteristics

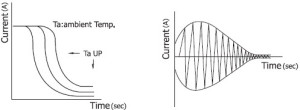

3.Current vs. Time Characteristics

This characteristic highlights the reliability needed for solid-state switches, particularly in heating and protection applications where high current is involved. When a voltage exceeding the specified limit is applied to a PTC thermistor, a large amount of current flows immediately due to the thermistor's initially low resistance. However, as the thermistor heats up, its resistance increases, limiting the current flow over time. This behavior is crucial for applications where quick response to high currents is needed, such as in overcurrent protection or thermal management systems.

Current \Time characteristics

Applications of PTC Thermistors

- Time Delay: PTC thermistors are used to introduce a time delay in circuits. This delay allows the thermistor to heat up and switch from a low-resistance state to a high-resistance state. The time delay depends on factors like the thermistor's size, temperature, applied voltage, and the circuit it’s used in. Common applications include delayed switching relays, timers, electric fans, and more.

- Motor Starting: PTC thermistors are used in motor circuits, particularly for startup windings. When the circuit is turned on, the thermistor has a low resistance, allowing current to flow through the startup winding. As the motor begins to operate, the thermistor heats up, causing its resistance to increase and effectively disconnecting the startup winding from the power supply. The time it takes for this to happen depends on the motor's startup requirements.

- Self-Regulating Heaters: When a switching PTC thermistor is part of a heating circuit, it self-regulates its temperature. If the temperature drops, the resistance decreases, allowing more current to flow, which causes the device to heat up. Conversely, if the temperature rises, the resistance increases, limiting the current and cooling the device. This feature is commonly used in self-regulating heaters.

PTC thermistors are also used as timers in the degaussing coil circuits of CRT displays. A degaussing circuit that uses a PTC thermistor is simple, reliable, and cost-effective.

NTC Thermistor

An NTC thermistor (Negative Temperature Coefficient) has the opposite behavior of a PTC thermistor. Its resistance decreases as the temperature increases. These thermistors are typically made from a sintered metal oxide or a cast chip of semiconductor material.

NTC thermistor

NTC Thermistor Construction and Types

NTC thermistors are typically made from metal oxide materials, with the most common oxides being manganese, nickel, cobalt, iron, copper, and titanium. These thermistors are classified into two main groups based on how the electrodes are attached to the ceramic body:

- Bead-Type Thermistors Bead-type thermistors are made from a platinum alloy and lead wires, which are directly sintered into the ceramic body. They offer high stability, reliability, fast response times, and can operate at high temperatures. These thermistors are compact and have relatively low dissipation constants. Bead-type thermistors are often connected in series or parallel circuits and come in the following types: Bare Beads Glass-Coated Beads Ruggedized Beads Miniature Glass Beads Glass Probes Glass Rods Bead-in-Glass Enclosures

- Metalized Surface Contacts The second group of NTC thermistors has metalized surface contacts, which are available with radial or axial leads, or without leads for mounting via spring contacts. These contacts are typically applied through painting, spraying, or dipping, and are fixed into the ceramic body. These thermistors include the following types: Disks Chips Surface Mounts Flakes Rods Washers

Typical Characteristics of NTC Thermistors

NTC thermistors are used in various applications where their electrical characteristics are essential. The three main electrical characteristics that need to be considered are:

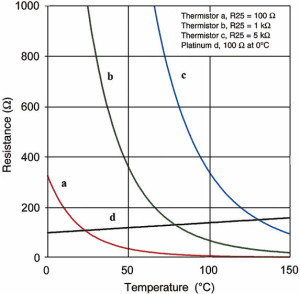

- Resistance-Temperature Characteristics NTC thermistors exhibit negative temperature characteristics, meaning their resistance decreases as the temperature increases. This behavior is typically seen when the resistance slightly increases as the temperature drops, as shown in the figure. This negative temperature coefficient makes them ideal for temperature-sensing applications where precise measurements and responses are required.

Resistance-Temperature Characteristic

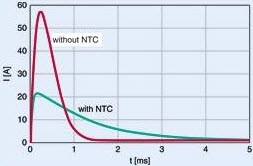

- Current-Time Characteristics

The current-time characteristics of an NTC thermistor show that the rate of change of current is slow due to the high resistance of the thermistor. As the thermistor heats up and approaches its equilibrium condition, the current change rate gradually decreases. Eventually, the current stabilizes, and the thermistor reaches its final value over time, as shown in the figure below. This characteristic is essential in applications where a steady-state current is required, and the thermistor helps control the current flow by adjusting its resistance in response to temperature changes

Current-Time Characteristics

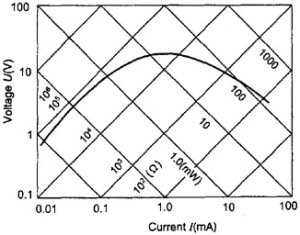

2.Voltage-Current Characteristic

In the voltage-current characteristic of an NTC thermistor, once the thermistor reaches a self-heated equilibrium condition, the rate of heat loss from the device equals the power being supplied to it. The relationship between voltage and current can be observed in the figure below, where the voltage initially decreases at a current of 0.01 mA. As the current increases to a peak value of 1.0 mA, the voltage then rises. After reaching the peak, the voltage starts to decrease again as the current value rises to 100 mA. This behavior highlights the thermistor's unique ability to regulate voltage and current as it heats up, making it useful for applications requiring precise control of power flow.

Voltage-Current Characteristic

Applications of NTC Thermistors

- Surge Protection: NTC thermistors are commonly used for surge protection in electronic devices. When powered on, the thermistor initially has a high resistance, which limits the current. As it heats up, its resistance decreases, allowing more current to flow. This process helps absorb and control surge currents, protecting sensitive components from damage.

- Temperature Control and Alarm: NTC thermistors are also used in temperature control systems or alarms. As the temperature increases, the resistance of the thermistor decreases, which leads to an increase in current. This change can trigger an alarm or activate a heating system, providing an efficient way to monitor and control temperature in various applications.

These are the two main types of thermistors used in different temperature-sensing applications. Understanding the characteristics, applications, and types of thermistors can give you a deeper and more comprehensive understanding of their role in electrical and electronic projects.

Frequently Ask Questions

What types of thermistors are there?

There are two main types of thermistors: Negative Temperature Coefficient (NTC) and Positive Temperature Coefficient (PTC). NTC thermistors have a lower resistance as the temperature rises, while PTC thermistors have a higher resistance as the temperature increases. They can also come in different forms, such as bead, disc, chip, or rod, and be packaged in materials like glass or epoxy.

What are PTC and NTC thermistors?

Thermistors are classified based on how they behave with temperature. NTC thermistors decrease in resistance as temperature goes up, whereas PTC thermistors increase in resistance as temperature rises.

What is a 10K Type 2 thermistor?

A 10K Type 2 thermistor is a type of temperature sensor that's mounted in a waterproof stainless steel probe. It's highly sensitive and responds quickly to temperature changes. It's commonly used by many popular DDC manufacturers.

Which is better, PTC or NTC?

The choice between PTC and NTC thermistors depends on the application. PTC thermistors have higher resistance as they heat up, making them ideal for overcurrent protection. NTC thermistors, on the other hand, have lower resistance as they warm up and are often used in temperature sensing or current limiting.

What are the four main types of temperature sensors?

The four main temperature sensors used in electronics today are:

- NTC thermistors

- Resistance Temperature Detectors (RTDs)

- Thermocouples

- Semiconductor-based Integrated Circuit (IC) sensors

Do thermistors work with AC or DC?

Thermistors can work with either DC or RMS AC current, depending on the application. The maximum steady-state current is usually specified for a given operating temperature, often at 65°C.

Is silicon a PTC or NTC device?

Silicon-based thermistors, also known as "silistors" or KTY devices, are typically PTC devices. As the temperature rises, their resistance increases.

How can I identify the type of thermistor?

To identify whether a sensor is a thermistor or an RTD, and its specific type, measure the resistance between the two differently coloured wires. For example, an RTD PT100 has a resistance of 100 ohms at 0°C, while an RTD PT1000 has 1,000 ohms at 0°C.

Subscribe to JMBom Electronics !