Guide to Potentiometers in Circuit Design

Catalog

What Is a Potentiometer?Different Types of PotentiometersHow Do Potentiometers Work?What Distinguishes Potentiometers from Rheostats?Are Potentiometers and Rotary Encoders Equivalent?Potentiometer Resistance RatingsA Word About Potentiometer TaperHow to Choose the Right PotentiometerRelated ArticlesIn this text, we’ll explore potentiometers in detail, covering what they are, their construction and symbol, how they work, the various types available, and their applications as both a rheostat and a voltage divider.

What Is a Potentiometer?

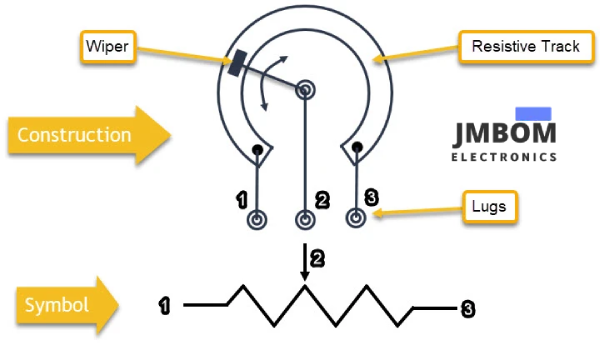

A potentiometer, often referred to as a “pot” in engineering circles, is essentially a type of resistor that features a mechanical adjustment mechanism that allows for manual alteration of its resistance. As we are aware, resistors provide a set resistance value and impede or “resist” the flow of electric current within a circuit. At its core, a potentiometer is a variable resistor.

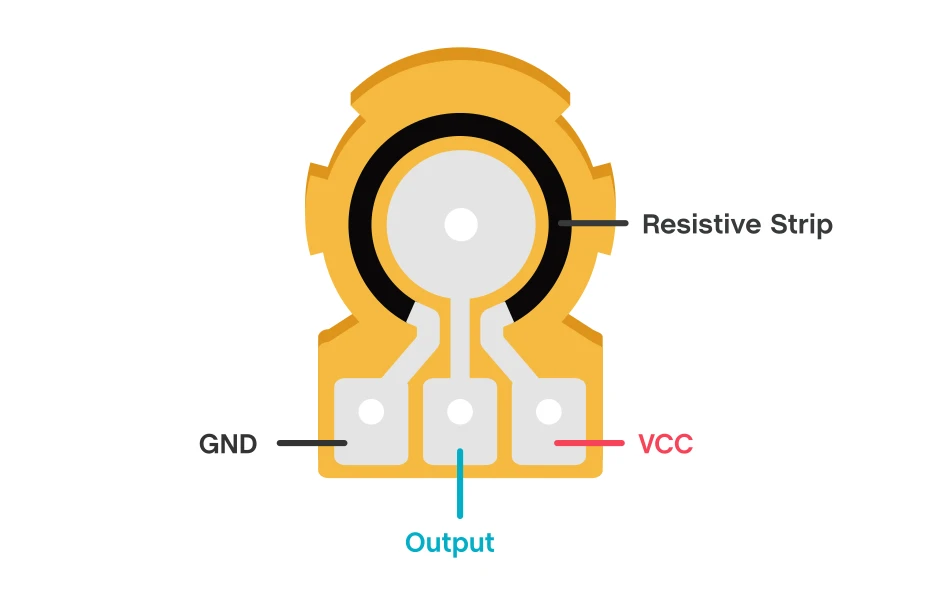

Potentiometers serve as voltage dividers that can be utilized to both regulate the voltage output to a circuit and precisely measure (or meter) electric potential — which is where the name “potentiometer” originates. They generate a continuously variable voltage output signal that is proportional to the physical position of the wiper on the resistive element. These components are passive, meaning they do not require a power source or additional circuits to operate.

A Short History of Potentiometers

Amid the surge in research and development related to electricity in the early 1800s, the idea of a component that could control the quantity of electricity entering a device or circuit was investigated by numerous individuals. However, the concept of the potentiometer was not put forward until 1841. It wasn’t until 1872 that Thomas Edison invented the first functional carbon potentiometer.

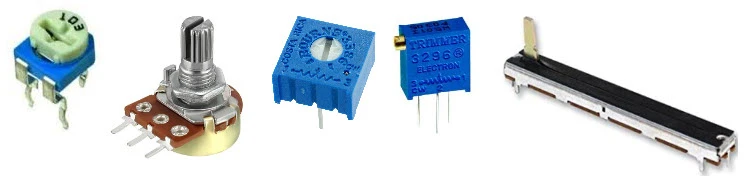

Today’s potentiometers are considerably smaller and more precise than their predecessors and come in a wide range of types and packages based on their intended application. They are frequently employed in various devices and systems to control values such as light intensity, audio volume and signals, and video brightness and color. Additionally, they can function as position sensors.

Different Types of Potentiometers

Potentiometer Types Comparison

| Type | Features | Advantages | Typical Applications |

| Rotary Potentiometer | Circular motion, knob or dial for adjustment | Durable, precise control | Volume control in audio equipment, industrial control systems |

| Linear Potentiometer | Straight-line motion, proportional control | Direct and proportional control | Position sensing in robotics, automotive throttle control |

| Slider Potentiometer | Sliding knob, user-friendly interface | Intuitive, easy manual adjustment | Sound mixing boards, lighting controls |

| Trimmer Potentiometer | Compact size, fine-tuning adjustment | Precise, stable, small form factor | Circuit tuning and calibration, setting biasing levels |

| Digital Potentiometer | Digital signals, no mechanical movement | High precision, programmable, no wear | Digital audio systems, automated test equipment |

How Do Potentiometers Work?

The resistance of an object depends on several factors. When all other conditions remain the same, resistance is directly proportional to the object's length. For example, a 10 cm object made of the same material with the same cross-sectional area will have half the resistance of a 20 cm object. Potentiometers operate based on this principle. The adjustable output is achieved by moving a sliding contact along a uniform resistive element, either in a straight line or a rotary motion, altering the path length through which current flows. The input voltage is applied across the entire resistive element, while the output voltage is measured as the drop between the fixed resistive element and the sliding or rotating contact. The position of the movable contact determines how much of the input voltage is applied to the circuit.

Potentiometers typically control low power levels, rarely exceeding one watt, as dissipating higher power would generate excessive heat. Instead, they adjust analog signals, which other components then use to control power. For instance, a basic light dimmer employs a potentiometer to control a TRIAC, which regulates the brightness of the light.

What Distinguishes Potentiometers from Rheostats?

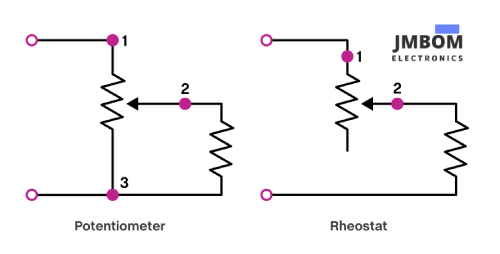

At its simplest, the key difference between these two components is that a potentiometer is a three-terminal device designed for voltage control, whereas a rheostat is a two-terminal device intended for current control. However, by leaving one terminal of a potentiometer unconnected, it can effectively be used as a rheostat.

Rheostats are typically high-wattage, wire-wound variable resistors employed in high-current applications to regulate the current flowing to devices like lamps and motors. They consist of coils of heavy-duty wire that adjust resistance in incremental steps by altering the position of the sliding element on the resistive element. Rheostats are not specified by their resistance value, but rather by their capacity to handle high power levels.

Potentiometer vs rheostat

Are Potentiometers and Rotary Encoders Equivalent?

A rotary encoder is an electro-mechanical device that converts the angular position or motion of a shaft into a digital signal. While both potentiometers and rotary encoders detect shaft rotation, they operate on different principles, offer varying levels of complexity, and require different setups.

Potentiometers are fundamentally analog devices, although digital versions do exist. Rotary encoders are digital devices that use binary logic to indicate position, necessitating a separate circuit to convert their output into a usable signal.

Potentiometers are easier to set up than rotary encoders, allow for infinitely variable inputs, can divide voltage in a non-linear manner, and can easily control other analog devices. In contrast, rotary encoders can rotate continuously, produce a digital signal, and offer excellent resolution. Although they tend to be more expensive than potentiometers, their precision in motor control makes them ideally suited for industrial, automation, and robotics applications.

Potentiometer Resistance Ratings

Potentiometers are generally characterized by their total resistance value, which represents the resistance between the two outer terminals of the device. For instance, a potentiometer rated at 1 kΩ (kilohms) has a resistance equivalent to that of a 1 kΩ fixed resistor across its resistive track.

Other key parameters to consider include:

- Rated Power: The maximum power the potentiometer can handle without being damaged.

- Resolution: The precision of the potentiometer, defined as the percentage of total resistance and the incremental resistance change with each movement of the contact along the resistive track.

- Sliding Noise: The level of electrical noise generated by the movement of the internal contact parts.

- Temperature Coefficient: The variation in resistance caused by changes in the operating temperature.

- Mechanical Life: The device's durability, typically measured in the number of cycles it can complete while maintaining its performance.

A Word About Potentiometer Taper

Potentiometer taper refers to how the resistance changes as the armature rotates or the wiper moves along the resistive element. In some designs, this change follows a linear pattern, meaning that when the armature or wiper is positioned in the middle, the resistance is half of the total resistance of the potentiometer.

Other designs feature a non-linear, logarithmic taper (also known as an audio taper), which more accurately reflects the logarithmic response of human hearing. This results in a smoother and more balanced volume adjustment throughout the full range of movement in audio controls. There are also reverse logarithmic potentiometers, designed to work in the opposite manner, often used in counterclockwise-operating audio controls.

How to Choose the Right Potentiometer

When choosing a potentiometer, it's important to take several key factors into account to ensure it fits your application’s needs:

Resistance value: Select a resistance value that aligns with your circuit requirements. Standard values range from a few ohms to several megaohms. Make sure the chosen value offers the control range you need.

Tolerance: Review the tolerance rating, which indicates how much the actual resistance may deviate from the nominal value. A lower tolerance (e.g., ±1%) offers greater accuracy, while a higher tolerance (e.g., ±20%) provides less precision.

Physical size: Ensure the potentiometer's size is appropriate for the available space in your design. Consider the form factor—such as rotary, linear, or trimmer—based on design limitations and user interface requirements. Power rating: Check the potentiometer’s power rating to confirm it can handle the power levels in your circuit without overheating or failing, especially in high-current or high-voltage applications.

Application type: Choose a potentiometer that’s suited to your specific application. For instance, rotary potentiometers are often used in audio devices, linear potentiometers in position sensing, and trimmer potentiometers for fine-tuning circuit performance.

Quality and Reliability Tips

Material quality: Choose potentiometers made from durable materials like conductive plastic or cermet to enhance performance and longevity. Environmental resistance: Ensure the potentiometer can withstand environmental challenges, such as temperature changes, humidity, or vibration, depending on your application.

Lifespan and durability: Consider the expected lifespan, often measured in cycles, to ensure the potentiometer can meet your application’s durability requirements.

By considering these aspects, you can select a potentiometer that provides reliable, long-term performance for your specific needs.

Related Articles

LR44 VS SR44: Are LR44 and SR44 Interchangeable?

What's the difference between the LM2576 and LM2596?

LR44 vs 357 Batteries: What are the Differences? (Ultimate Guide)

74LS08 AND Gate IC:Applications,Features & FAQ

Subscribe to JMBom Electronics !