Engine Coolant Temperature Sensor: Overview, Function & Circuit Design

Catalog

IntroductionWhat Is an Engine Coolant Temperature Sensor?How Does an ECT Sensor Work?Where Is the Engine Coolant Temperature Sensor Located?Engine Coolant Temperature Sensor SpecificationsSymptoms of a Faulty Engine Coolant Temperature SensorCommon Causes of ECT Sensor FailureAdvantages of the Engine Coolant Temperature SensorDisadvantages of the Engine Coolant Temperature SensorApplications of Engine Coolant Temperature SensorsSummaryEngine Coolant Temperature Sensor FAQRelated ArticlesIntroduction

The history of the engine coolant temperature sensor (ECT) aligns with the evolution of thermal sensing technologies, notably in the 19th and 20th centuries. These sensors typically rely on thermistors or RTDs and are now standard components in modern vehicle systems. The ECT sensor plays a key role in automotive performance by tracking the temperature of the engine coolant and sending this information to the Powertrain Control Module (PCM). The PCM then uses this input to optimize various functions such as ignition timing, fuel delivery, and overall engine behavior. Accurate coolant temperature readings are essential for maximizing engine efficiency, reducing emissions, and maintaining proper fuel consumption. This article provides an in-depth look at how ECT sensors work and where they’re used.

What Is an Engine Coolant Temperature Sensor?

An Engine Coolant Temperature (ECT) sensor—also known as a Coolant Temperature Sensor (CTS)—is a compact component integrated into a vehicle’s cooling system. Its main role is to detect the temperature of the engine’s coolant and relay this data to the Engine Control Unit (ECU). This helps the ECU monitor and manage the engine's operating temperature in real time.

How Does an ECT Sensor Work?

The ECT sensor operates on the principle of resistance variation with temperature. It typically uses a thermistor whose resistance decreases as the coolant temperature rises. This change in resistance alters the voltage signal sent to the ECU. Based on this input, the ECU adjusts engine functions such as air-fuel ratio and ignition timing to ensure optimal performance under various driving conditions. In essence, the ECT sensor enables the engine to run efficiently by helping maintain an ideal temperature range.

Where Is the Engine Coolant Temperature Sensor Located?

These sensors are typically positioned near the thermostat housing or directly mounted on the engine block. The Engine Control Unit (ECU) relies on data from the ECT sensor to maintain the optimal engine temperature. This helps prevent both undercooling and overheating, which could otherwise result in engine damage or reduced performance.

Engine Coolant Temperature Sensor Specifications

Below are the common specifications for a typical ECT sensor:

- ECT sensors use a Negative Temperature Coefficient (NTC) thermistor, meaning their resistance decreases as temperature increases.

- These sensors usually have a 2-wire configuration.

- When the engine is cold (around 20°C), the resistance is relatively high—typically between 2000 and 3000 ohms.

- When the engine is warm (around 90°C), the resistance drops significantly, often to 200–300 ohms.

- At lower temperatures, the sensor outputs a higher voltage signal (e.g., ~2V).

- At higher temperatures, the signal voltage decreases (e.g., ~0.5V).

- The ECU interprets this voltage to assess the coolant’s temperature in real time.

- Operating temperature range is generally from -40°C to 185°C.

- Measurement accuracy may vary by sensor model but is generally within a few degrees Celsius.

- These sensors feature a fast response time, which allows for real-time engine adjustments.

- They are built with a sealed connector to withstand harsh engine environments.

- Construction materials typically include a brass sensor body, a Fluorocarbon O-ring for sealing, and a PBT (30% glass-filled) plastic connector for enhanced durability.

ECT Sensor Circuit Overview

The Engine Coolant Temperature Sensor (ECT) is a key thermal sensor designed to monitor the temperature of the engine’s coolant. Installed in or near the engine’s cylinder head, this sensor can influence the activation of the radiator fan or adjust emissions control functions. It forms part of a closed-loop circuit with the ECU, sending real-time voltage signals corresponding to coolant temperature changes, ensuring the engine operates efficiently under varying conditions.

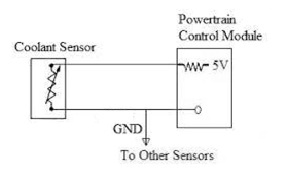

Wiring and Circuit Description of the Coolant Temperature Sensor

The engine coolant temperature sensor typically uses a two-wire setup: one wire carries a 5V reference signal from the Powertrain Control Module (PCM), and the other is a ground (GND) connection, which returns to the PCM.

The PCM (Powertrain Control Module) is the main vehicle control unit, combining the functions of both the ECM (Engine Control Module) and TCU (Transmission Control Unit). It interprets input signals from various sensors—including the coolant temperature sensor—to manage engine and transmission performance.

Coolant Sensor Circuit with PCM

The diagram below (not shown) represents a basic ECT sensor circuit integrated with the PCM. The sensor acts as a variable resistor based on temperature—specifically, a thermistor that changes its resistance as coolant temperature fluctuates. Most ECT sensors are Negative Temperature Coefficient (NTC) types, meaning their resistance decreases as temperature increases.

How It Works

In this setup, one pin of the sensor is connected to a constant 5V supply from the PCM, while the second pin is grounded back to the PCM. As the engine warms up, the temperature of the coolant increases, causing the resistance in the sensor to drop. This drop in resistance leads to a lower voltage signal being returned to the PCM.

Conversely, when the engine is cold, the sensor’s resistance is higher, resulting in a higher voltage being sent back to the PCM.

The PCM continuously monitors this return voltage to estimate the current coolant temperature. Based on this data, the PCM can activate various engine functions—such as turning on the radiator fan or adjusting emissions control systems—to maintain optimal engine performance and prevent overheating.

Symptoms of a Faulty Engine Coolant Temperature Sensor

A malfunctioning engine coolant temperature (ECT) sensor can lead to a range of noticeable issues in engine behavior and performance, including:

- Erratic or non-working temperature gauge: The dashboard temperature display may read inaccurately or fail entirely, making it difficult to monitor engine heat levels.

- Fuel injection irregularities: The ECU may receive incorrect temperature readings, leading to improper fuel delivery and poor air-fuel mixture.

- Rough idling or engine shaking: Incorrect temperature data can result in unstable idle speed and engine vibrations, especially during cold starts.

- Excessive fuel consumption and power loss: Inaccurate coolant data can prevent the engine from running efficiently, leading to reduced fuel economy and weakened engine output.

- Black smoke from the exhaust: Over-fueling due to faulty readings can result in incomplete combustion and visible exhaust smoke.

- Cooling fan running constantly or at high speed: A short or open circuit in the sensor may cause the ECU to activate the radiator fan unnecessarily, as a safety fallback.

Common Causes of ECT Sensor Failure

Several factors can lead to the failure or degradation of an ECT sensor over time. These include:

- Natural wear and aging: Like many electronic components, ECT sensors can wear out after prolonged use and exposure to engine heat.

- Electrical connection problems: Loose, corroded, or damaged connectors can disrupt signal transmission between the sensor and the ECU.

- Contaminated coolant: Engine coolant mixed with rust, sludge, or other debris can damage the sensor or interfere with its operation.

- Thermal stress: Constant exposure to extreme temperatures or sudden temperature changes may cause sensor material fatigue and eventual malfunction.

- Coolant leaks: Leaking coolant near the sensor can expose it to moisture or corrosive chemicals, leading to premature failure.

- Manufacturing defects: In some cases, poor-quality sensors or production flaws can cause early failure even under normal conditions.

Advantages of the Engine Coolant Temperature Sensor

The Engine Coolant Temperature (ECT) sensor offers several important benefits in modern vehicle systems:

- Accurate coolant temperature monitoring: It delivers precise readings that enable the ECU to adjust ignition timing and fuel delivery for peak engine performance.

- Enhanced fuel efficiency: By optimizing fuel injection based on real-time engine temperature, it helps improve fuel economy.

- Improved engine operation: Smooth engine performance is supported through better combustion control enabled by temperature-based adjustments.

- Overheat protection: The sensor helps prevent engine overheating by signaling the ECU to activate the radiator fan or engage other cooling mechanisms.

- Prevention of engine damage: Maintaining optimal operating temperatures reduces stress on engine components and extends their lifespan.

- Real-time diagnostics: It provides continuous feedback that supports troubleshooting, preventative maintenance, and system health monitoring.

- Early fault detection: Potential cooling system issues can be identified early, helping to avoid costly repairs through proactive intervention.

- Driver feedback: It supplies data to the dashboard temperature gauge, allowing drivers to keep an eye on engine temperature in real time.

Disadvantages of the Engine Coolant Temperature Sensor

Despite its benefits, the ECT sensor also comes with a few limitations:

- Non-linear signal output: Some sensors have a non-linear voltage response over a wide temperature range, requiring calibration or compensation in the ECU.

- Self-heating effects: Electrical current passing through the sensor can cause minor heating, which may lead to inaccurate readings under certain conditions.

- Susceptibility to damage: These sensors can be delicate and prone to failure from extreme engine heat, vibration, or physical impact.

- Variable cost: Price can vary depending on quality, material, and manufacturer.

- Inaccurate readings when faulty: A defective sensor can send incorrect temperature signals, resulting in misleading gauge readings and hidden overheating issues.

- Cooling system malfunctions: If the sensor fails to detect high engine temperatures, it may prevent the cooling system from activating, risking engine overheating.

- Negative impact on emissions: A malfunctioning ECT sensor can interfere with proper emissions control, potentially increasing exhaust emissions.

- Radiator fan issues: A faulty sensor may cause the fan to run continuously or not at all, both of which can affect engine temperature regulation.

- Reduced engine performance: Without accurate coolant temperature data, the ECU may not be able to optimize engine parameters, leading to a loss of power and efficiency.

Applications of Engine Coolant Temperature Sensors

Engine Coolant Temperature Sensors (ECTS) play a crucial role in modern automotive systems. Their applications include the following:

- Real-time engine temperature monitoring: The ECT sensor continuously measures the temperature of the engine coolant and sends this data to the ECU (Engine Control Unit), allowing it to adjust various engine parameters for optimal performance, emissions control, and fuel efficiency.

- Fuel injection control: Based on the coolant temperature, the ECU adjusts fuel injection timing and quantity to ensure efficient combustion under different engine conditions—especially during cold starts or warm operation.

- Air-fuel ratio optimization: The sensor enables the ECU to determine the ideal air-fuel mixture based on current engine temperature, promoting cleaner and more efficient combustion.

- Cooling system management: The ECT sensor signals the ECU to activate or deactivate the radiator fan and other cooling components, helping to prevent engine overheating.

- On-Board Diagnostics (OBD) integration: As a key input to the vehicle’s OBD system, the ECT sensor helps the ECU detect irregularities in engine temperature behavior, supporting error detection and diagnostic trouble codes (DTCs).

- Emission reduction: By ensuring that the engine operates within its optimal temperature range, the ECT sensor contributes to complete fuel combustion and reduced harmful emissions.

- Preventative maintenance: Monitoring coolant temperature helps detect early warning signs of engine overheating or cooling system issues, allowing for timely maintenance and avoiding costly repairs.

Summary

In essence, the ECT sensor is a thermistor-based device that changes its resistance with temperature. It sends a corresponding voltage signal to the Powertrain Control Module (PCM), which then interprets this signal to manage fuel delivery, ignition timing, and cooling functions. Common examples of ECT sensors include models used by GM and Ford.

Engine Coolant Temperature Sensor FAQ

What happens if the coolant temperature sensor fails?

When the coolant temperature sensor malfunctions, it can send incorrect signals to the ECU. This may cause improper adjustments to the fuel mixture and ignition timing, leading to issues such as:

- Engine overheating

- Poor fuel economy

- Difficulty starting the engine

- Rough idling or stalling

- Increased emissions

In some cases, the engine may run too rich (excess fuel) or too lean (insufficient fuel), which can harm engine components over time.

Can I drive without a working temperature sensor?

Technically, your vehicle may still run, but driving without a functioning temperature sensor is risky and not recommended. Without it, you lose real-time engine temperature data, which can:

- Lead to unnoticed overheating

- Disable the temperature gauge or warning light

- Cause serious engine damage due to uncontrolled temperature regulation

Do I really need to replace a faulty coolant temperature sensor?

Yes, it's important to replace a bad coolant temperature sensor as soon as possible. Common warning signs include:

- Inaccurate or fluctuating temperature readings

- Check Engine light turning on

- Reduced fuel efficiency

- Engine overheating

Continuing to drive with a faulty sensor can cause significant long-term damage and expensive repairs.

Can a bad coolant temperature sensor affect my AC system?

Yes, it can. In many vehicles, if the sensor mistakenly tells the ECU that the engine is overheating, the ECU may disable the air conditioning system to reduce engine load. This can result in poor AC performance or complete AC shutdown.

What does it mean if the engine coolant temperature warning light turns on?

If this warning light comes on (typically shown as a red or yellow thermometer icon), it usually means:

- The engine is overheating

- The coolant level is too low

- There’s a cooling system malfunction

If the light is red, stop the vehicle immediately to prevent severe engine damage. Let the engine cool down and check the coolant level or call for roadside assistance if needed.

What is a thermistor?

A thermistor is a type of resistor whose resistance value varies significantly with temperature. In ECT sensors, a Negative Temperature Coefficient (NTC) thermistor is typically used—meaning resistance decreases as temperature increases.

Related Articles

OPT3007 Ultra-Thin Ambient Light Sensor Overview and Applications

TPS7A26 LDO Regulator: Functionality and Key Applications

Guide to Low Dropout (LDO) Regulators and How They Work

ESP32-S3 Development Board: Pinout Diagram, Key Features, Technical Specs

DS18B20 Waterproof Temperature Sensor: Overview, Operation, and Common Uses

BAT54A Schottky Diode: Pinout and Common Uses

Infineon ILD8150E LED Driver IC Overview

LF353N Op-Amp Explained: Pinout, Features, and How It Works

ADXL335 Accelerometer Sensor: Pinout, Specs, Features, and How It Works

Subscribe to JMBom Electronics !