Metal Oxide Film Resistors: Structure, Operation and Key Specs

Catalog

What Is a Metal Oxide Film Resistor?SpecificationsConstruction of Metal Oxide Film ResistorsWorking Principle of Metal Oxide Film ResistorsCharacteristics of Metal Oxide Film ResistorsMetal Oxide Film Resistor Color CodeAdvantages of Metal Oxide Film ResistorsDisadvantages of Metal Oxide Film ResistorsApplications of Metal Oxide Film ResistorsFrequently Ask QuestionsRelated ArticlesMetal oxide film resistors are one of the earliest alternatives to carbon composition resistors. Compared to metal film resistors, they are relatively simple and cost-effective to produce.

To understand these components, it's important to know that metal oxides are compounds formed through the chemical bonding of oxygen with other elements. For example, tin oxide—created by combining tin and oxygen—is commonly used in the manufacturing of these resistors.

Metal oxide film resistors are widely used in electronic circuits due to their better performance and stability when compared to both carbon composition and carbon film resistors.

In this article, we’ll explore the construction, working principle, specifications, and typical applications of metal oxide film resistors.

Metal Oxide Film Resistors

What Is a Metal Oxide Film Resistor?

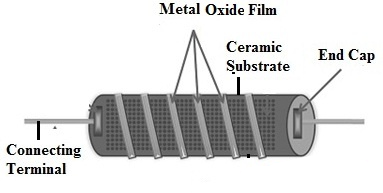

A metal oxide film resistor is a type of fixed-value, axial-lead resistor made by coating a ceramic rod with a thin layer of metal oxide—typically tin oxide. It's important not to confuse these with metal oxide varistors, which are made from materials like silicon carbide or zinc oxide and serve different purposes. Metal oxide film resistors are commonly used in circuits where power dissipation is a key requirement. The basic construction of a metal oxide film resistor is illustrated below.

Specifications

Below is a performance overview of metal oxide film resistors:

- Tolerance options: ±1%, ±2%, ±5%, ±10%

- Resistance range: 1 Ω to 10 MΩ

- Maximum noise level: 0.2 µV/V

- Temperature coefficient: ±300 ppm/°C

- Voltage coefficient: 0.0005%/V

- Maximum operating temperature: Up to 300°C

- Stability: Excellent long-term performance stability

- Surge handling: Capable of withstanding overloads and high surge currents

- Standard tolerance: Typically ±5%

Construction of Metal Oxide Film Resistors

The construction of a metal oxide film resistor is similar to that of a metal film resistor, with the key difference being the material used for the resistive film. Instead of using pure metal, these resistors use a combination of tin oxide and antimony oxide to form the resistive layer. This metal oxide mixture acts as the current-limiting element, providing the desired resistance.

Metal Oxide Film Resistor Construction

The resistive film is typically applied to a ceramic substrate using a chemical vapor deposition (CVD) process. During this process, pure metal compounds react with gas under low pressure and high temperature, forming a stable oxide layer. One common method involves heating the resistor body in tin chloride vapor, which results in the formation of a uniform tin oxide film.

In some variants, the film is first formed using a thin metal layer, which is then oxidized through exposure to oxygen. This controlled oxidation process allows the resistance value to be fine-tuned by adjusting the film’s composition and thickness.

Working Principle of Metal Oxide Film Resistors

Once the metal oxide film is deposited onto the ceramic body, the desired resistance value is precisely adjusted by making a helical (spiral) cut along the film. Today, this is typically done using laser trimming, though older methods included sandblasting or grinding.

The spiral cut increases the length of the resistive path, which in turn significantly raises the resistance—sometimes by up to a hundred times. This cutting process allows for fine-tuning of resistance values with high accuracy.

The final resistance of the resistor depends on several key factors:

- The amount of antimony oxide mixed with the tin oxide

- The width and depth of the helical cut

- The thickness of the metal oxide film layer

By precisely controlling these variables, manufacturers can produce resistors with highly accurate and stable resistance values.

Characteristics of Metal Oxide Film Resistors

Metal oxide film resistors offer several advantages and trade-offs compared to other common resistor types. Below are their key characteristics:

- Superior performance in areas such as voltage rating, power handling, surge resistance, high-temperature operation, and overload capacity when compared to carbon film and even some metal film resistors.

- Preferred for high-endurance applications due to their robustness and thermal stability.

- Lower precision and stability than metal film resistors—making them less ideal for high-accuracy circuits.

- Relatively poor tolerance performance for low resistance values, typically offering wider tolerances than metal film types.

- Higher temperature coefficient (typically around ±300 ppm/°C), meaning their resistance changes more with temperature than metal film resistors.

- Use tin oxide as the primary resistive material, which is doped with antimony oxide to adjust resistivity.

- The resistance value is influenced by the amount of antimony oxide, film thickness, and width of the spiral cut.

- Withstands higher operating temperatures compared to carbon and standard metal film resistors.

- Noise characteristics are comparable to those of carbon film resistors—not as quiet as metal film types.

Metal Oxide Film Resistor Color Code

Like most cylindrical through-hole resistors, metal oxide film resistors are marked with color bands to indicate their resistance value and tolerance. These follow the standard resistor color code system, which is shared with carbon film, metal film, wirewound, and fusible resistors.

Resistors typically have 4 to 6 color bands:

- The first two (or three) bands indicate significant digits,

- The next band represents the multiplier,

- And the final band shows the tolerance.

You can refer to the standard Resistor Color Code Chart to decode these markings quickly

Advantages of Metal Oxide Film Resistors

Metal oxide film resistors offer several notable benefits, including:

- High performance compared to carbon film and even some metal film resistors

- Widely used in high-endurance applications by engineers and designers

- More affordable than carbon composition resistors

- Excellent surge current handling capabilities

- Can operate at higher temperatures than many other resistor types

- Known for their stability and long-term reliability

- Compact size makes them suitable for space-constrained designs

- Lower noise generation, making them more suitable for sensitive analog circuits

Disadvantages of Metal Oxide Film Resistors

Despite their strengths, metal oxide film resistors also come with a few limitations:

- Not suitable for high-frequency applications

- Less commonly used today, as newer resistor technologies have become more popular

- Installation can be more difficult, especially compared to surface-mount resistor types

Applications of Metal Oxide Film Resistors

Metal oxide film resistors are used in a variety of applications, especially where reliability and heat resistance are important:

- Commonly used as standard fixed resistors in general-purpose electronic circuits

- Suitable for power dissipation needs above 1 watt

- Preferred in designs where high thermal and electrical stability is required

- Used in medical devices, telecommunications equipment, and industrial systems

- Found in power electronics circuits where wattage handling is critical

This covers a complete overview of metal oxide film resistors—including how they work, their characteristics, pros and cons, and real-world uses. These resistors use a metal oxide film as the resistive element to control current flow precisely in a circuit.

Frequently Ask Questions

What are the four types of resistors?

Different Types Of Resistors

- Table of Contents

- Linear Resistors.

- Fixed Resistors.

- Variable Resistors.

- Non-Linear Resistors

What is the Use of a Metal Oxide Film Resistor?

Metal oxide film resistors are used in moderate-power electronic applications, typically handling power levels of a few watts. These resistors feature a resistive film made from metal oxides (such as tin oxide mixed with antimony oxide). While less precise than metal film resistors (with a typical temperature coefficient around ±350 ppm/°C), they are cost-effective, durable, and suitable for circuits that require heat resistance, surge protection, or high reliability at a reasonable price.

Are Metal Oxide Film Resistors Good?

Yes, metal oxide film resistors—especially the thick film types—are considered versatile and reliable. Their key advantages include:

- Good durability and long-term stability

- Strong overload and surge resistance

- Flameproof coatings for safety

- Affordable for most applications

They are not ideal for precision analog circuits, but they perform well in power circuits, general-purpose applications, and harsh environments.

What Is a Common Application for a Metal Oxide Varistor (MOV)?

Metal oxide varistors (not to be confused with metal oxide film resistors) are used for overvoltage protection. Common applications include:

- Power strips and AC line protection

- Consumer electronics (e.g., cameras, phones, MP3 players)

- Industrial systems and data equipment to guard against voltage spikes or surges

MOVs act as surge suppressors, clamping high voltages and protecting sensitive components.

Where Are Metal Film Resistors Used?

Metal film resistors are used in applications where precision and low noise are critical:

- Analog circuits (e.g., amplifiers, filters)

- Digital circuits (e.g., clock and counter circuits)

- Measurement and audio systems

They offer tight tolerances and a low temperature coefficient, making them ideal for stable, low-noise environments.

Are Metal Film Resistors Flameproof?

Yes. Many metal oxide and metal film resistors come with a flame-retardant coating, especially those used in power-sensitive circuits. This coating helps the resistor withstand overloads without catching fire or being physically damaged.

What Happens If You Don’t Use a Resistor in a Circuit?

If a resistor is omitted where required:

- Excessive current may flow

- Components can overheat, burn, or explode

- Wires may melt, and circuits can be damaged or destroyed

Resistors are essential for current limiting, voltage division, and circuit protection.

What’s the Difference Between MFR and BFR (Non-electronics context)?

In pharmaceutical and chemical manufacturing:

- MFR (Master Formula Record): A standardized, official document containing the complete formulation and manufacturing process.

- BFR (Batch Formula Record): A production-specific document based on the MFR, used to record actual production data for a specific batch.

Related Articles

Voltage Amplifier: Circuit Design, Gain, vs. Power Amplifier, and Key Applications

Resistor-Transistor Logic (RTL):Operation, Features, and Applications

Diode-Transistor Logic (DTL): Circuit Design,Truth Table, and Applications

2N5089 NPN Transistor: Overview, Pinout, and Common Uses

ESP32-S2 Development Board: Pinout, Features & Specs

ADXL335 Accelerometer Module: Pin Configuration, Features & Internal Components

Preamplifiers: What They Are, How They Work, Types and Differences

Subscribe to JMBom Electronics !