Semiconductor Fuse: Structure, HSN Code, Operation, and Common Uses

Catalog

What Is a Semiconductor Fuse?Construction of a Semiconductor FuseHow a Semiconductor Fuse WorksSemiconductor Fuse vs. HRC FuseSemiconductor Fuse SelectionSemiconductor Fuse CharacteristicsHow to Test a Semiconductor FuseApplications of Semiconductor FusesSemiconductor Fuse – Frequently Asked QuestionsRelated ArticlesA fuse is a protective electrical component designed to safeguard circuits from issues like overloads or excessive current. The concept of the electric fuse was introduced by Thomas Alva Edison in 1890. While fuses are available in various shapes and sizes, their core function remains the same. They are generally categorized into AC fuses and DC fuses. In this article, we focus on a specific type of DC fuse — the semiconductor fuse — exploring its design, how it works, and where it is typically used.

What Is a Semiconductor Fuse?

A semiconductor fuse, also known as a high-speed fuse, ultra-rapid fuse, or rectifier fuse, is a type of overcurrent protection device specifically engineered to safeguard sensitive semiconductor components. These include thyristors, SCRs (silicon-controlled rectifiers), rectifiers, diodes, and power supply units. Designed to react quickly, semiconductor fuses are fast-acting and current-limiting, helping to minimize peak let-through current and providing low I²t (melting energy) values. Typically, these fuses are rated between 125V and 2,100V and come in a variety of shapes and sizes to suit different applications. The symbol used for a semiconductor fuse is shown below.

Semiconductor Fuse Symbol

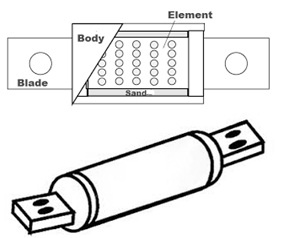

Construction of a Semiconductor Fuse

The structure of a semiconductor fuse includes a fuse element that is embedded in a filler material and enclosed within a durable fuse body. The fuse element itself is typically made from fine silver, chosen for its resistance to oxidation and its high melting point of around 960°C, which allows it to withstand the fuse's maximum operating temperatures. The outer body is usually constructed from thermally stable aluminum oxide ceramic, providing both mechanical strength and heat resistance.

Semiconductor fuses are also known as high-breaking capacity (HBC) fuses or current-limiting fuses. In some contexts, they may also be referred to as ultra-fast or rectifier fuses. The duration from the onset of overcurrent to the point when the fuse element melts is known as the pre-arcing time.

Semiconductor Fuse Construction

How a Semiconductor Fuse Works

A semiconductor fuse functions by allowing current from the power source to pass through and supply the connected circuit under normal conditions. However, in the event of an overload or short circuit, the excessive current causes the fuse element (filament) to melt or break, instantly cutting off the power and disconnecting the circuit. Once the current exceeds the predefined threshold, the fuse reacts quickly to isolate the faulty part of the system, preventing further damage.

Semiconductor fuses are designed to respond much faster than standard fuses, making them ideal for protecting sensitive components such as transistors, integrated circuits (ICs), and diodes. Due to their fast response time and high precision, they are increasingly used in place of conventional AC and DC fuses in many applications.

Semiconductor Fuse vs. HRC Fuse

The key differences between a semiconductor fuse and a High Rupturing Capacity (HRC) fuse are outlined below.

Semiconductor Fuse vs. HRC Fuse

| Feature | Semiconductor Fuse | HRC (High Rupturing Capacity) Fuse |

|---|---|---|

| Construction | Made with materials suited for protecting semiconductor devices. | Constructed using metal elements placed between two contacts. |

| Speed of Operation | Very fast-acting (ultra-rapid response). | Relatively slower in operation compared to semiconductor fuses. |

| Current Rating | Typically designed for lower current ratings. | Suitable for higher current ratings. |

| Application Area | Used to protect sensitive components like MOSFETs, IGBTs, thyristors, and diodes, especially where fast response is critical. | Commonly used to protect motors, capacitors, and other high-power equipment in power factor correction panels. |

| Response to Faults | Extremely fast disconnect time during short circuits and overcurrent conditions. | Has a slower disconnect time in comparison, which may not be suitable for delicate electronics. |

Semiconductor Fuse Selection

Selecting the right semiconductor fuse involves meeting specific application and protection requirements. Key selection criteria include:

- Continuous Current Rating: The fuse must be capable of carrying the device's rated current continuously under normal operating conditions.

- I²t Coordination: The fuse’s I²t value (melting energy) should be lower than the protected device’s I²t rating to ensure the fuse blows before the device is damaged during fault conditions.

- Voltage Withstand Capability: The fuse must withstand the voltage that appears across it after arc interruption.

- Peak Arc Voltage: The peak arc voltage generated when the fuse blows should remain below the maximum voltage rating of the protected semiconductor device.

- Practical Considerations: Fuse selection should also take into account factors such as: I²t rating Voltage rating Breaking capacity Fuse class (gS, gR, aR, gPV, etc.) Physical size and mounting limitations Compatibility with the fuse holder Available ratings for each package type Continuous current rating requirements

In particular, when selecting a semiconductor fuse for soft starters, special attention should be given to the protection of thyristors and ensuring adequate current handling during startup and steady-state conditions.

Semiconductor Fuse Characteristics

The current-time characteristics of semiconductor fuses illustrate how quickly they respond to overcurrent conditions. These fuses are designed to act rapidly and are well-suited for protecting sensitive electronic components.

Semiconductor Fuse Characteristics

When connected in series with semiconductor devices, such as thyristors or IGBTs, a fast-acting fuse will open the circuit as soon as the current exceeds its rated value. This quick disconnection minimizes energy let-through and helps prevent component damage.

Semiconductor Fuse Operation: Current-Time Behavior

When a semiconductor fuse is not installed in a circuit, a fault condition allows the current to rise unchecked until it reaches a critical level, marked as point B. As current increases, so does the temperature of the system.

However, when a fuse is present, the fault current begins to rise but is interrupted at a specific moment, denoted as time t = tm (melting time). At this point, the fuse element melts and opens the circuit, producing an electrical arc.

- The current briefly peaks at point A, known as the Peak Let-Through Current, marked as point C on the current-time graph.

- At point C, the arc resistance increases, which causes the fault current to drop.

- At point D, the arc is extinguished, and the current falls to zero.

The total fault-clearing time (tc) is the sum of:

- tm – the time taken for the fuse element to melt, and

- ta – the time for the arc to extinguish, so tc = tm + ta.

The voltage across the fuse during the arcing period is known as the Arcing Voltage or Recovery Voltage. For safe operation, the I²t rating of the fuse must always be lower than that of the SCR or any protected semiconductor device to ensure proper coordination and protection.

HSN Code for Semiconductor Fuses

The HSN code (Harmonized System of Nomenclature) is an internationally accepted system developed by the World Customs Organization (WCO) to classify goods for customs and tax purposes. It typically uses a 6-digit code, though some countries expand this to 8 digits for more detailed classification.

For semiconductor fuses, the standard HSN code is:

853610 – which falls under the category for “Fuses, of a kind used for the protection of electrical circuits.”

How to Test a Semiconductor Fuse

To test a semiconductor fuse, follow these steps:

- Isolate the Circuit: Make sure the capacitor or load connected to the fuse is disconnected for accurate results.

- Apply Test Voltage: Use a controlled voltage source to apply voltage across the fuse terminals.

- Measure Current Flow: Monitor the current response: If the fuse is intact, it will allow a current to flow within its normal range. If the fuse is blown, the circuit will show little to no current flow.

In more advanced setups, testers may use a dual-current measurement system where:

- The first current level indicates a functional (unbroken) fuse,

- The second current level (typically zero or very low) signals a blown fuse.

Applications of Semiconductor Fuses

Semiconductor fuses are specially designed for the protection of sensitive electronic components in power and industrial systems. Their ultra-fast response time makes them ideal for the following applications:

- Protection of Semiconductor Devices Used to safeguard components such as thyristors, IGBTs, diodes, and power transistors in circuits where high-speed fault interruption is essential.

- Power Conversion Systems Commonly used in power rectifiers, AC and DC motor drives, inverters, converters, and soft starters to protect semiconductor components from overcurrent conditions.

- Power Electronics Equipment Widely applied in systems such as: Variable Frequency Drives (VFDs) Thyristor-based DC drives Uninterruptible Power Supplies (UPS) Photovoltaic (solar) inverters Solid-state relays Welding inverters

- Circuit Protection Functions These fuses provide protection against: Short circuits Overvoltage Overcurrent High dV/dt (slew rate) Thermal shutdown (TSD) Reverse current blocking (RCB)

- High-Current Applications Typically used with large semiconductor devices that handle 100A or more, ensuring fast disconnection before damage occurs.

Semiconductor fuses play a critical role in protecting modern power electronic systems. With ultra-fast acting characteristics, they are purpose-built to protect high-value semiconductor devices from short circuits and fault currents.

Semiconductor Fuse – Frequently Asked Questions

What is a semiconductor fuse?

A semiconductor fuse—also known as an ultra-rapid fuse, high-speed fuse, or rectifier fuse—is a fast-acting, current-limiting device designed to protect sensitive semiconductor components. These include devices such as diodes, thyristors, IGBTs, and SCRs. Its quick response to overcurrent conditions helps prevent damage to high-value electronic systems.

What is the difference between a semiconductor fuse and an HRC fuse?

| Semiconductor Fuse | HRC (High Rupturing Capacity) Fuse |

|---|---|

| Very fast-acting | Relatively slower response time |

| Typically used for low-current, sensitive devices (e.g., MOSFETs, IGBTs) | Designed for high-current applications (e.g., motors, industrial loads) |

| Provides protection for semiconductor-based systems | Used in general-purpose heavy-duty power distribution |

Why is a semiconductor fuse used in a Variable Frequency Drive (VFD)?

Semiconductor fuses are essential for protecting the sensitive internal components of a VFD, especially during short circuits or fault conditions. While motor circuit breakers might provide general protection, semiconductor fuses are more precise and faster, making them far more effective in protecting power electronics like IGBTs and rectifiers within the drive.

How do you check if a semiconductor fuse is blown?

To test a semiconductor fuse:

- Isolate the circuit (e.g., disconnect the capacitor/load).

- Apply voltage across the fuse using a testing apparatus.

- Measure current response: A normal current level indicates the fuse is intact. A lack of current or secondary low current level indicates the fuse is blown.

What does “semiconductor” mean in electricity?

A semiconductor is a material that partially conducts electricity. Unlike conductors (which allow free electron flow) and insulators (which block it), semiconductors can control current flow when voltage is applied. They are the foundation of modern electronics, found in transistors, diodes, and integrated circuits.

Why should you never replace a fuse with a higher-rated fuse?

Replacing a fuse with a higher current rating than specified can be dangerous:

- The fuse may not blow during an overload, allowing excessive current to continue flowing.

- This can lead to overheating, damaged components, or electrical fires.

- Always match the fuse rating to the manufacturer’s specifications to ensure safety.

Can I use a penny as a fuse replacement?

Absolutely not. Using a penny (or any non-fuse object) bypasses circuit protection entirely. Unlike a fuse, a penny will not melt or break during overcurrent, which can result in serious electrical damage or fire hazards. This is extremely unsafe and strongly discouraged.

Why use a semiconductor fuse?

Semiconductor fuses offer ultra-fast protection for critical electronic components. They:

- React instantly to short circuits and overcurrent events

- Minimize let-through energy, preserving the health of sensitive semiconductors

- Prevent costly downtime and equipment failure

Related Articles

Voltage Amplifier: Circuit Design, Gain, vs. Power Amplifier, and Key Applications

Resistor-Transistor Logic (RTL):Operation, Features, and Applications

Diode-Transistor Logic (DTL): Circuit Design,Truth Table, and Applications

2N5089 NPN Transistor: Overview, Pinout, and Common Uses

ESP32-S2 Development Board: Pinout, Features & Specs

ADXL335 Accelerometer Module: Pin Configuration, Features & Internal Components

Preamplifiers: What They Are, How They Work, Types and Differences

Metal Oxide Film Resistors: Structure, Operation and Key Specs

Subscribe to JMBom Electronics !