Air Core Inductors: Design, Operation, Inductance, and Common Uses

Catalog

What Is an Air Core Inductor?ConstructionWorking PrincipleDifference Between Air Core Inductor and Solid Core InductorAdvantages of Air Core InductorsDisadvantages of Air Core InductorsApplications of Air Core InductorsFrequently Ask QuestionsRelated ArticlesAn inductor is an electrical device primarily used to store energy in the magnetic field created when current flows through it. Typically, inductors are made by winding a conducting wire into a coil around a core — each loop of wire is called a winding. The inductance of the coil depends directly on the number of these windings. Among various types of inductors, the air core inductor stands out as one that uses a non-magnetic core, often referred to as an air core coil. These inductors are ideal for applications that require low inductance values and operate at high frequencies. This article provides an overview of air core inductors, including how they work and where they are commonly used.

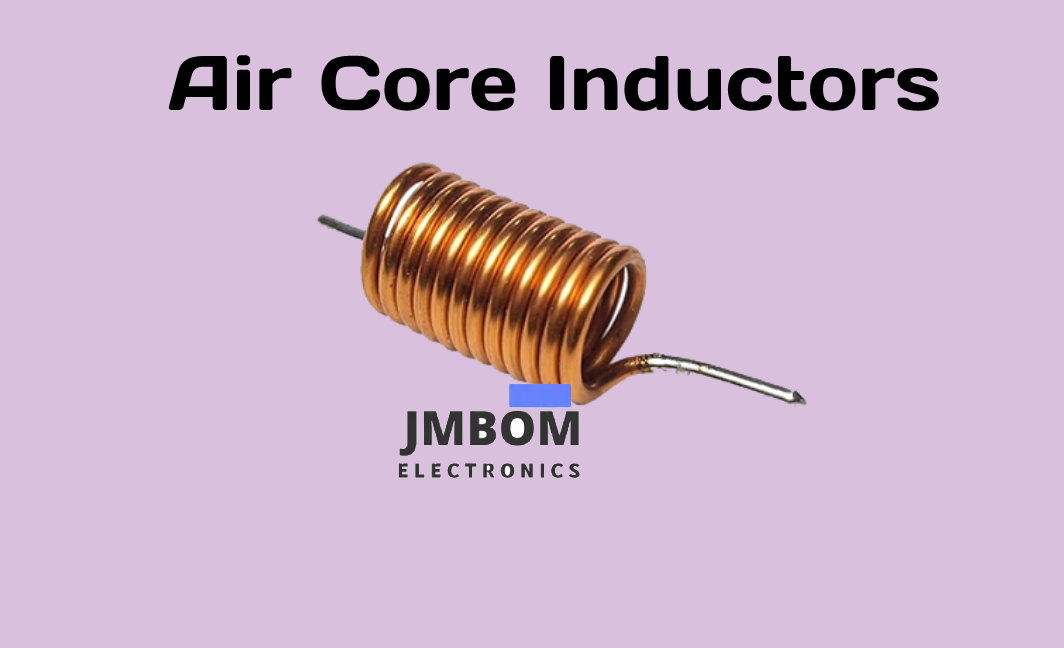

What Is an Air Core Inductor?

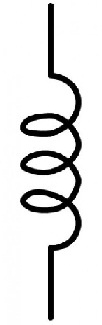

An air core inductor, also called an air coil inductor, is a type of inductor made by winding a wire coil without any magnetic core inside. Using air as the core results in a lower maximum inductance compared to inductors with ferrite or iron cores, but it also significantly reduces energy losses. Because there are no core-related losses, air core inductors can operate effectively at very high frequencies. Below is the standard symbol used to represent an air core inductor.

Air Core Inductor Symbol

These inductors are used when a low amount of inductance is needed, and since they have no core, there are no core losses. However, to achieve the desired inductance, they require more coil turns compared to inductors with magnetic cores. Ceramic inductors are often referred to as air core inductors. They offer effective performance, especially in switch-mode applications, where high frequency, excellent linearity, and minimal core loss are important.

Construction

An air core inductor is basically made by winding multiple turns of wire into coils around a simple non-magnetic form, often made of cardboard, ceramic, or plastic for insulation. The coil is wrapped around a hollow space inside the form, which is filled with air—hence the name “air core inductor.” In this design, air itself acts as the core material.

Construction of Air Core Inductor

Working Principle

Air core inductors operate on the principle that air has very low electrical conductivity, resulting in a relatively low inductance and a weaker magnetic field. Due to this weaker magnetic field, air core inductors allow current to rise more quickly and help minimize signal loss. This is especially beneficial because signal loss tends to occur when inductors generate strong magnetic fields within a circuit.

Difference Between Air Core Inductor and Solid Core Inductor

The key differences between air core and solid core inductors are as follows:

Air Core Inductor vs. Solid Core Inductor

| Feature | Air Core Inductor | Solid Core Inductor |

|---|---|---|

| Core Material | No solid core inside the coil | Contains a solid magnetic core inside the coil |

| Size | Generally smaller and lighter | Typically larger and heavier |

| Inductance Value | Lower inductance values | Higher inductance values |

| Cost | More affordable | Usually more expensive |

Inductance of an Air Core Inductor

The inductance of a single-layer air core inductor can be calculated using the formula:L=d2×n218d+40zL = \frac{d^2 \times n^2}{18d + 40z}L=18d+40zd2×n2

Where:

- D is the diameter of the coil

- n is the number of turns in the coil

- z is the length of the inductor

The resulting inductance L is typically measured in microhenries (μH).

Advantages of Air Core Inductors

- Simple and straightforward construction.

- No saturation issues, iron losses, or core distortion, making them ideal for high-frequency use.

- Inductance is not affected by the current level passing through the coil.

- Eliminates iron core losses since there is no magnetic core.

- Performs well at high frequencies without core losses or signal distortion.

- Generally more cost-effective compared to core-based inductors.

- Minimal signal loss even at high magnetic field strengths.

- Can operate effectively up to frequencies around 1 GHz, whereas ferromagnetic core inductors start losing efficiency beyond 100 MHz.

Disadvantages of Air Core Inductors

- Tend to be physically larger in size compared to solid core inductors.

- Typically have a lower Q factor, meaning less efficiency in energy storage.

- Cannot achieve very high inductance values easily.

- Require more coil turns to match the inductance of an equivalent solid-core inductor.

- Air’s low electrical conductivity leads to low magnetic permeability, which results in lower inductance overall.

Applications of Air Core Inductors

Air core inductors are widely used in various electronic circuits and devices, including:

- Designing RF (radio frequency) tuning coils.

- Essential components in computers, TVs, communication devices, mobile chargers, and DVD players.

- Commonly used in snubber circuits, filter circuits, and other high-frequency applications such as television and radio receivers.

- Suitable for low-frequency applications ranging from 20 Hz to 1 MHz.

- Frequently employed for interstage coupling in circuits.

- Key components in RF and IF (intermediate frequency) tuning coils.

- Help achieve lower peak inductance while minimizing energy losses compared to ferrite core inductors.

- Used in radio transmitters to reduce harmonic vibrations when electromagnetic signals pass through them.

- Found in hi-fi stereo speakers to minimize sound distortion.

In summary, air core inductors offer effective solutions for switch-mode magnetic applications, especially where high frequency, high linearity, and low core loss are critical. They are also ideal when space constraints are not a major concern.

Frequently Ask Questions

What is an Air Core Inductor?

An air core inductor, also called an air coil inductor, is a type of inductor that has no magnetic core inside the coil—air acts as the core instead. The coil is usually made from copper wire, which is insulated, with either tinned or bare ends.

What is a Core Inductor?

A core inductor typically consists of a coil of conducting material (usually insulated copper wire) wound around a core. The core can be made of plastic (resulting in an air-core inductor) or a ferromagnetic material (like iron or ferrite), which is known as an iron core inductor.

What Are the Different Types of Inductors?

There are several common types of inductors, including:

- Air Core Inductor: Hollow coils with low permeability and low inductance.

- Iron Core Inductor

- Toroidal Inductor

- Laminated Core Inductor

- Powdered Iron Core Inductor

- Axial Inductor

- Shielded Surface Mount Inductor

- Coupled Inductor

What is the Difference Between Air Core and Ferrite Core Inductors?

Air core inductors are generally used for higher frequency applications, while ferrite core inductors are better suited for lower to moderate frequency ranges. Air cores have lower inductance but also lower losses, making them ideal for high-frequency tuning, whereas ferrite cores provide higher inductance and are used where size and inductance are more critical.

What is the Purpose of the Core in an Inductor?

The core material provides high magnetic permeability, which boosts the magnetic field strength and allows the inductor to store more energy. Iron-core inductors, for example, also have stronger magnetic coupling between coil windings.

What is the Best Type of Inductor?

For very high-frequency applications (above 100 MHz), air core inductors are preferred due to their low losses and high Q factor, making them ideal for RF circuits. Ferrite core inductors are better when you need higher inductance in a smaller package and operate up to about 100 MHz.

What is an Inductor in Simple Terms?

An inductor is a passive electronic component that stores energy temporarily in a magnetic field when electric current flows through its coil.

Why Use a Ferrite Bead Instead of an Inductor?

Ferrite beads are primarily used for electromagnetic interference (EMI) suppression and noise reduction, making them ideal for filtering high-frequency noise. Inductors, on the other hand, are better suited for energy storage, current control, and filtering in circuits.

What is the Best Core Material for an Inductor?

Powdered cores are often considered superior to other materials like ferrites or laminated steel in many applications. Designers choose among various powder core materials and shapes depending on the trade-offs between losses, cost, size, and ease of winding.

Related Articles

2N5089 NPN Transistor: Overview, Pinout, and Common Uses

ESP32-S2 Development Board: Pinout, Features & Specs

ADXL335 Accelerometer Module: Pin Configuration, Features & Internal Components

Preamplifiers: What They Are, How They Work, Types and Differences

Metal Oxide Film Resistors: Structure, Operation and Key Specs

Semiconductor Fuse: Structure, HSN Code, Operation, and Common Uses

DC Servo Motor: Structure, Operation, Arduino Interface & Common Uses

Iron Core Inductor : Construction, Formula, Working & Its Applications

Subscribe to JMBom Electronics !