Differential Pressure Sensors: Working Principle, Interfacing,Testing Methods and Common Issues

Catalog

What Is a Differential Pressure Sensor?How a Differential Pressure Sensor WorksDifferential Pressure Sensor CircuitInterfacing the MPX7002DP Differential Pressure Sensor with Arduino UnoTypes of Differential Pressure SensorsHow to Test a Differential Pressure SensorCommon Symptoms of a Faulty Differential Pressure SensorApplications of Differential Pressure SensorsFrequently Ask QuestionsRelated ArticlesIn some systems, it's not always necessary to measure the absolute pressure of a gas or liquid. Instead, what's often more important is the pressure difference between two specific points. In such scenarios, differential pressure sensors are used. These sensors compare the pressure before and after a component—such as a valve—in a pipeline. If the valve is fully open, the pressure on both sides should be nearly identical. Any discrepancy could indicate the valve isn’t entirely open or there may be a blockage. This article provides an overview of how differential pressure sensors work, how they are used, and where they are commonly applied.

What Is a Differential Pressure Sensor?

A differential pressure sensor is a device designed to measure the pressure difference between two distinct points in a system. Instead of reading the absolute pressure, it provides a relative pressure reading that reflects how much higher or lower one point is compared to the other. These sensors are known for their accuracy, durability, and consistency in performance.

The primary role of a differential pressure sensor is to deliver precise data about the pressure relationship between two locations within gases, liquids, or steam. These sensors are crucial for accurately detecting pressure differences and are widely used in process control, automation, and system monitoring. Their applications range from safety-critical environments to filter status monitoring and liquid level detection in sealed tanks.

These sensors typically operate based on capacitive sensing technology. They feature thin diaphragms positioned between two parallel metal plates. When external pressure is applied, the diaphragm slightly bends, which alters the capacitance. This change in capacitance results in a corresponding variation in the sensor’s output signal.

How a Differential Pressure Sensor Works

A differential pressure sensor functions by detecting the pressure difference between two points in a pipeline. At one location, it monitors the status of components like a particulate filter and ensures it’s working correctly. At another, it helps manage low-pressure exhaust gas recirculation (EGR) systems. These sensors typically include two input ports that allow tubing connections. The tubes are then easily routed to the specific points in the system where pressure measurement is required.

Differential Pressure Sensor Circuit

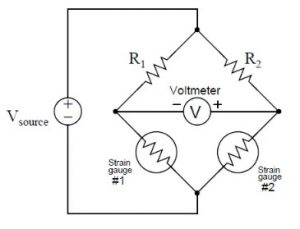

Below is a basic example of a differential pressure sensor circuit that uses two strain gauges. These gauges are carefully matched in terms of resistance. When a difference in pressure occurs, one strain gauge is compressed while the other is stretched. This mechanical deformation leads to an imbalance in the Wheatstone bridge circuit. The connected voltmeter detects this imbalance and translates it into a corresponding pressure reading:

Differential Pressure Sensor Circuit

By analyzing this circuit, we can identify the following key points:

- Determine which port is the high-pressure side: In this configuration, Port B is designated as the high-pressure port.

- Effect of an open-circuit failure in resistor R1: If the fixed resistor R1 becomes open (fails), the voltmeter will read full-scale high, indicating a significant imbalance in the bridge circuit.

- Identifying faulty components that cause a full-scale reading on the voltmeter: The following component failures can result in the voltmeter registering a maximum (upscale) output: Strain Gauge 1: A short-circuit failure. Strain Gauge 2: An open-circuit failure. Resistor R1: An open-circuit failure. Resistor R2: A short-circuit failure.

These failures disrupt the bridge balance significantly enough to push the output reading to the extreme end of the scale.

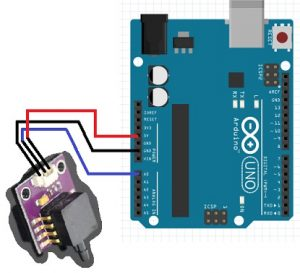

Interfacing the MPX7002DP Differential Pressure Sensor with Arduino Uno

The MPX7002DP differential pressure sensor can be easily interfaced with an Arduino Uno, making it suitable for developing open-source medical devices. These devices are often used by healthcare professionals to diagnose and manage various respiratory conditions. In this setup, a breakout board featuring the MPX7002DP sensor is utilized.

Required Components:

- MPX7002DP Differential Pressure Sensor

- Arduino Uno Board

Connection Overview:

- GND pin of the sensor → GND on the Arduino Uno

- +5V pin of the sensor → 5V on the Arduino Uno

- Analog output (OUT) of the sensor → A0 pin on the Arduino Uno

MPX7002DP Differential Pressure Sensor Interfacing with an Arduino Uno

This simple interface allows the Arduino to read analog pressure data from the MPX7002DP, enabling real-time monitoring for applications such as ventilators or airflow measurement tools.

Uploading the Code and Reading Sensor Data with Arduino

Once all the wiring is complete, you can upload the following code to the Arduino Uno to begin reading data from the MPX7002DP differential pressure sensor:

cppCopyEdit// MPX7002DP Test Code

// This code reads data from the MPX7002DP

// Sensor output connected to analog pin A0

int sensorPin = A0; // Define the analog input pin for the pressure sensor

int sensorValue = 0; // Variable to store the raw analog reading

float outputValue = 0; // Variable to store the converted pressure in kPa

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 bps

while (!Serial) {

; // Wait for the serial port to connect (only needed for some boards)

}

pinMode(sensorPin, INPUT); // Set the sensor pin as input

}

void loop() {

sensorValue = analogRead(sensorPin); // Read raw analog value

outputValue = map(sensorValue, 0, 1023, -2000, 2000); // Convert to pressure (approx. -2 to +2 kPa)

// Print results to Serial Monitor

Serial.print("Sensor Value: ");

Serial.print(sensorValue);

Serial.print("\tPressure (approx. kPa): ");

Serial.println(outputValue);

delay(100); // Short delay for ADC and sensor to stabilize

}

Code Explanation

- The analog output from the MPX7002DP is connected to A0 on the Arduino.

- The raw analog reading is stored in the sensorValue variable.

- This raw value is mapped to a pressure value in kilopascals (kPa) and stored in the outputValue variable (as a float).

- In the setup() function, serial communication is initialized, and the analog pin is configured as an input.

- The loop() function continuously reads the analog value, converts it, and sends the result to the Serial Monitor.

- A short 100 ms delay is included to allow the sensor and ADC to settle before taking the next reading.

- This loop repeats indefinitely, providing live pressure readings in real time.

⚠️ Note: The map() function in this example gives a rough approximation. For more accurate results, use the sensor’s transfer function based on its datasheet, and apply proper calibration.

Types of Differential Pressure Sensors

Differential pressure sensors come in several common types, including resistive, piezoelectric, capacitive, MEMS, and optical variants. Each type operates based on a different sensing principle and is suitable for specific applications.

Resistive Differential Pressure Sensors

Resistive-type sensors measure pressure changes through the variation in electrical resistance of a strain gauge. The strain gauge is typically attached to a diaphragm exposed to the pressure medium. It consists of a metal resistive element on a flexible substrate and may be bonded to or deposited directly on the diaphragm using thin-film techniques. Metal diaphragms offer high tolerance to overpressure and burst conditions.

In some designs, the strain gauge is applied to a ceramic diaphragm using thick-film deposition. These sensors are generally less tolerant of extreme pressures compared to their metal-diaphragm counterparts. Certain versions use semiconductor materials that exhibit significant resistivity changes under strain—up to 100 times greater than those seen in metal gauges. This high sensitivity allows for the detection of much smaller pressure differences.

Piezoelectric Differential Pressure Sensors

Piezoelectric sensors utilize materials that generate an electrical charge when subjected to pressure. The generated charge is directly proportional to the applied force, and its polarity indicates the direction of pressure. These sensors respond quickly to pressure changes, making them ideal for dynamic pressure monitoring in fast-changing environments.

Optical Differential Pressure Sensors

Optical sensors employ interferometric techniques to measure pressure-induced changes within an optical fiber. These sensors are immune to electromagnetic interference, making them suitable for harsh or noisy environments, such as near radiographic equipment. They can be miniaturized using MEMS technology and are biocompatible, making them suitable for medical or topical use. Optical sensors are capable of sensing pressure variations at multiple points along the fiber length.

MEMS-Based Differential Pressure Sensors

MEMS stands for Micro-Electro-Mechanical Systems. These sensors are micro-fabricated on silicon and may incorporate capacitive or piezoelectric sensing elements. Despite their small size (typically 2–3 mm per side), MEMS sensors offer high resolution and sensitivity. The low-level analog signal generated by the sensor is typically processed by onboard signal-conditioning electronics, which convert it to a usable analog or digital output. MEMS differential sensors are widely used due to their compact form factor and ease of integration in modern electronics.

How to Test a Differential Pressure Sensor

You can test a differential pressure sensor using a digital multimeter (set to 20V range) and a pressure gauge. Below is a step-by-step guide for accurate testing:

Step-by-Step Testing Procedure:

- Initial Setup: Connect the multimeter’s ground lead to the negative terminal of the battery. With the battery turned on (engine off), check the battery voltage. It should read approximately 12.6V.

- Identify Sensor Wires: Refer to the manufacturer’s service manual to identify the signal wire, ground (GND), and 5V reference wire. Use a back-probing method to access these wires without disconnecting the sensor.

- Ignition On, Engine Off: Turn the ignition key to the “ON” position without starting the engine: The 5V reference wire should read around 4.5–5V. The GND wire should show 0V. The signal wire should output a voltage in the range of 0.5–4.5V.

- Engine On, Monitor Signal: Start the engine and monitor the signal wire. Rev the engine and observe any changes in the signal voltage. A healthy sensor should show a change in voltage corresponding to pressure variations.

- Check Pressure with a Gauge: If the signal voltage does not change, inspect the sensor’s hoses using a pressure gauge. Carefully disconnect the hoses from the sensor while the engine is running. Measure the pressure in each hose using a low-range pressure gauge (0–15 PSI, such as an exhaust backpressure gauge).

- Compare Voltage and Pressure: Recheck the sensor signal voltage. It should fall between the two measured pressure values. If the voltage is highly erratic or does not correlate with actual pressure values, the sensor is likely faulty and should be replaced.

Common Symptoms of a Faulty Differential Pressure Sensor

A failing differential pressure sensor may exhibit the following signs:

Typical Failure Causes:

- Contamination (oil, soot, debris)

- Thermal damage from excessive engine heat

- Diaphragm failure—leading to loss of flexibility and responsiveness

- Vibration damage from prolonged exposure to harsh engine conditions

- Blocked ports due to debris or buildup inside the sensor tubing

Performance Issues:

- Poor engine performance or loss of power

- Misfiring or detonation

- Reduced fuel efficiency

- Excessive black smoke from the exhaust

- Overheating of the engine or transmission

- Check engine light illumination

- Hard starting or rough idling

When the sensor becomes clogged or unresponsive, it may fail to properly signal the PCM (Powertrain Control Module), leading to poor exhaust gas recirculation (EGR) and backpressure buildup.

Visual Inspection Tips Before Replacement

- Check the sensor connector: Look for cracked plastic, corrosion, or melted insulation.

- Inspect wiring: Replace any frayed, damaged, or burnt wires.

- Examine sensor hoses: Look for cracks, melting, or signs of abrasion.

- Check for blockages: If hoses appear physically intact, ensure they're not clogged. Clear or replace them as needed.

Pro Tip: When replacing damaged hoses, consider rerouting them to avoid future heat or vibration damage.

Applications of Differential Pressure Sensors

Differential pressure sensors are used in a wide range of industries and applications, thanks to their ability to accurately detect pressure differences across two points. Below are some common and critical use cases:

Medical Applications

- Used in the treatment of deep vein thrombosis (DVT).

- Incorporated in infusion pumps, ventilators, respiratory monitoring devices, and breathing detection systems.

Industrial & Process Control

- Widely employed in flow measurement, liquid level or depth sensing, and leak detection.

- Critical for monitoring and controlling fluid flow in subsea oil & gas processing, effluent treatment plants, and district heating systems using hot water or steam.

- Used to track differential pressure in pipelines to assess flow rates of liquids and gases.

Automation & HVAC Systems

- Essential in cleanrooms, HVAC systems, and building automation for maintaining pressure balance and air quality.

- Deployed in isolation rooms, pharmaceutical labs, data centers, and hospital environments for sensitive air pressure monitoring.

Filter & Safety Monitoring

- Used to monitor filter performance, signaling when filters are clogged or need replacement.

- Commonly integrated into safety-critical systems to ensure process reliability and early fault detection.

- Found in fire suppression systems, especially in sprinkler units to monitor operational pressure.

Flow Measurement Equipment

- Supports accurate measurements in systems using Venturi tubes, orifice plates, Pitot tubes, and similar flow-based devices.

- Enables safe tank level measurement by monitoring pressure differentials in closed vessels.

General Use

- Suitable for monitoring non-aggressive and non-flammable gases in precise measurement devices.

- Helps manage process control loops, ensuring systems operate efficiently and safely.

Importance of Calibration

Pressure sensors—like any other measuring instrument—can be affected over time by thermal, mechanical, or chemical stress, leading to issues such as:

- Zero drift

- Hysteresis

- Loss of accuracy

These effects can compromise safety and reduce process efficiency. While regular calibration cannot prevent these shifts, it helps in early detection. Therefore, it's recommended to perform annual calibration for both electrical and mechanical pressure measurement devices to maintain reliability and performance.

Final Note:

Differential pressure sensors are vital components in automation, healthcare, industrial control, and safety systems. Their high sensitivity and accuracy make them indispensable for reliable operation across many applications.

Frequently Ask Questions

What Does a Differential Pressure Sensor Do?

A differential pressure sensor measures the difference in pressure between two points within a system. It’s commonly used to detect flow rates, monitor filter conditions, or identify blockages. Unlike absolute pressure sensors, which measure pressure relative to a vacuum, differential sensors compare two separate pressure inputs directly.

What Is a DPS Sensor Used For?

A Differential Pressure Sensor (DPS) monitors the pressure drop between two locations in a flow system. In automotive applications, it’s typically installed across the exhaust system—such as before and after the diesel particulate filter (DPF)—to monitor filter performance and determine when regeneration is needed.

What Is a Differential Pressure Flow Sensor?

A differential pressure flow sensor measures the flow of gases, steam, liquids, or natural gas by calculating the pressure drop across a restriction (like an orifice plate or Venturi tube). This pressure-flow relationship allows the system to determine flow rate with accuracy based on fluid dynamics principles.

How Do You Know If a Differential Pressure Sensor Is Failing?

Signs of a faulty differential pressure sensor, particularly in diesel vehicles, include:

- Poor engine performance

- Reduced fuel economy

- Elevated engine temperatures

- Inability of the DPF to regenerate properly These symptoms can trigger warning lights or diagnostic trouble codes (DTCs) on the vehicle’s dashboard.

What Happens When a Pressure Sensor Goes Bad?

A failing pressure sensor may lead to:

- Incorrect or fluctuating pressure readings

- Erratic system behavior

- Warning lights (e.g., check engine light)

- Improper engine response or performance issues Timely diagnosis is essential to prevent damage to engine components or safety systems.

How Much Does It Cost to Replace a DPF Pressure Sensor?

The cost of replacing a DPF pressure sensor depends on the vehicle make and model. Typically, professional replacement services start at £229 for most vehicles, including parts and labor. Always consult a qualified mechanic for an accurate estimate.

Can You Drive with a Faulty DPF Pressure Sensor?

While the car may still run with a malfunctioning sensor, it is not recommended. Continued driving can cause:

- Reduced fuel efficiency

- Engine performance issues

- Excessive soot buildup

- Potential engine damage In addition, a faulty DPF sensor will cause an MOT test failure due to emissions non-compliance.

Why Is Differential Pressure Important?

Differential pressure is crucial because it provides insights into system performance and health. It helps:

- Monitor flow rates

- Detect leaks or blockages

- Evaluate filter condition By tracking pressure differences, operators can optimize efficiency, maintain safety, and schedule preventative maintenance effectively.

Related Articles

DS18B20 Waterproof Temperature Sensor: Overview, Operation, and Common Uses

BAT54A Schottky Diode: Pinout and Common Uses

Infineon ILD8150E LED Driver IC Overview

LF353N Op-Amp Explained: Pinout, Features, and How It Works

ADXL335 Accelerometer Sensor: Pinout, Specs, Features, and How It Works

Engine Coolant Temperature Sensor: Overview, Function & Circuit Design

Crankshaft Position Sensor: Overview, Circuit Function& Comparison with Camshaft Sensors

Inverting Summing Amplifier: Circuit Diagram,Operation and Formula

Active Bandpass Filter: Overview, Types,Q Factor & Applications

Passive High-Pass Filter: Overview, Circuit Design & Transfer Function

Subscribe to JMBom Electronics !